3.

1.

1.

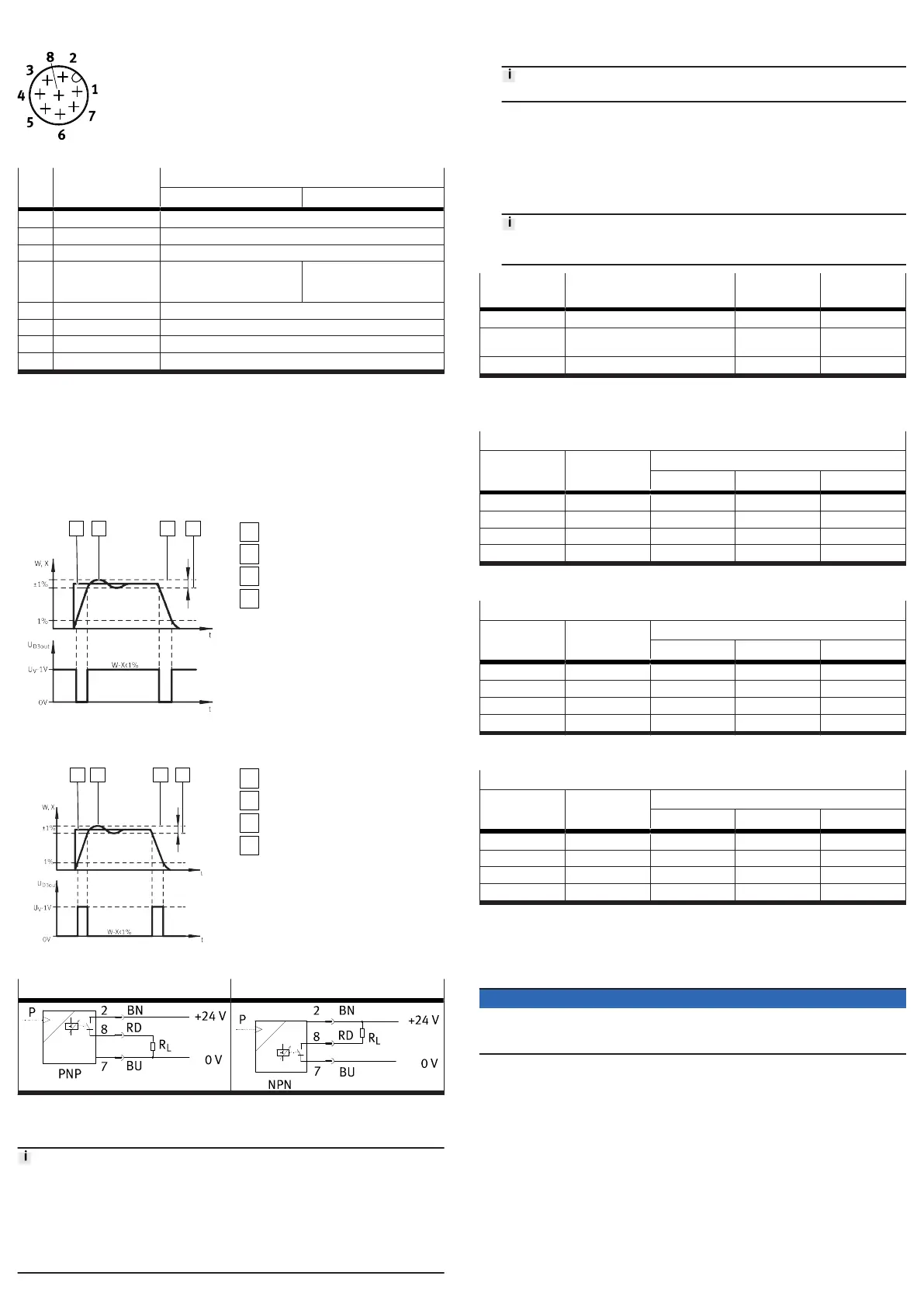

Pin allocation

The pins on the electrical connection are assigned as follows:

Fig. 5: Pin allocation

PIN Wire colour

1)

Port identifications

VPPM-...-V1... VPPM-...-A4...

1 white (WH) Digital input D1

2 brown (BN) +24 V DC supply voltage

3 green (GN) Analogue input W- (- setpoint value)

4 yellow (YE) Analogue input W+

(+ setpoint value)

0 … 10 V

Analogue input W+

(+ setpoint value)

4 … 20 mA

5 grey (GY) Digital input D2

6 pink (PK) Analogue output X (actual value)

7 blue (BU) GND supply earth

8 red (RD) Digital output D3

2)

1) With usage of the plug socket with cable as specified in accessories.

2) The hysteresis of the digital comparator output D3 is 0.5% FS.

Tab. 3: Pin allocation

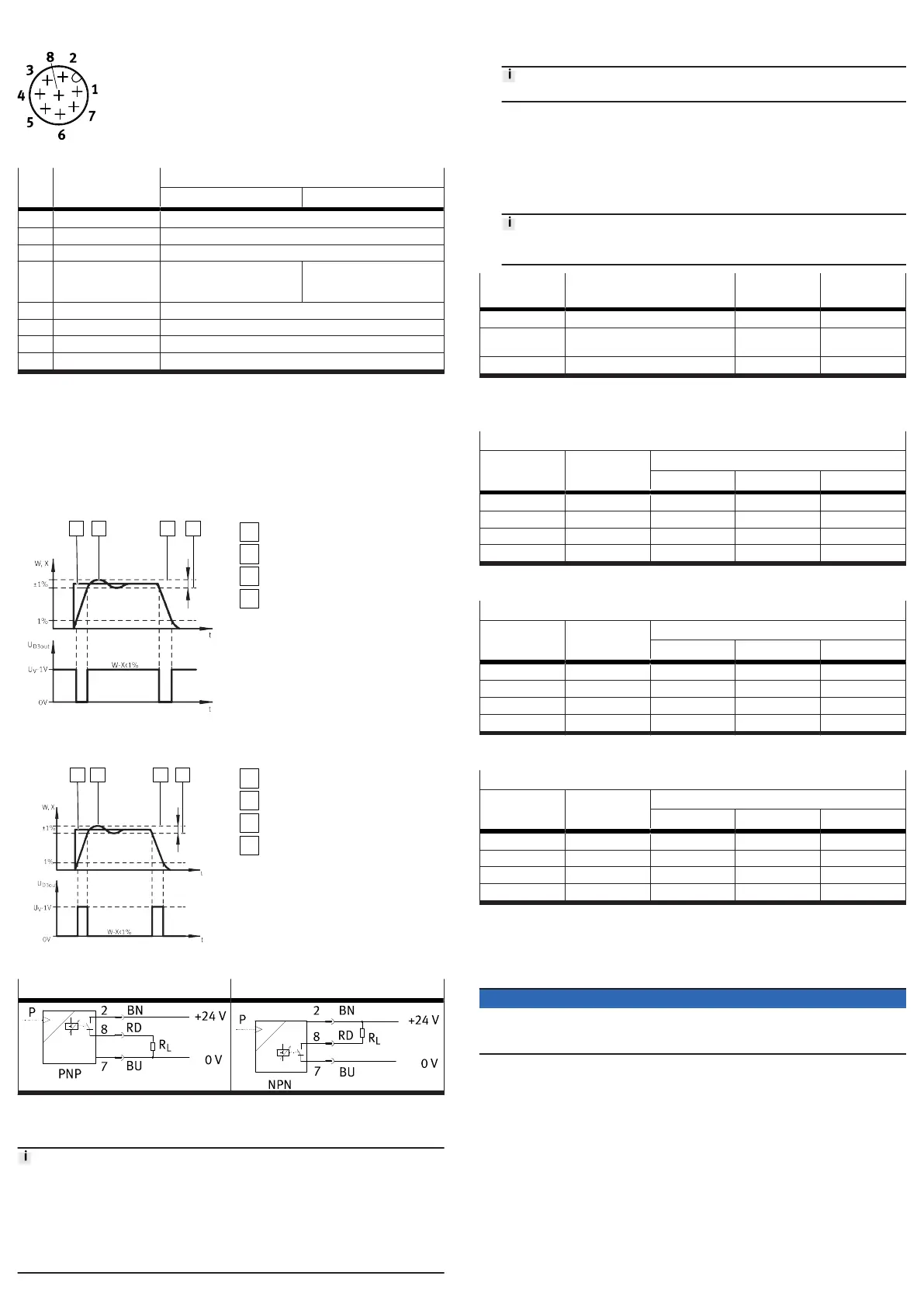

Digital comparator output D3

The “Pressure reached” function permits monitoring of the pressure control func-

tion. The setpoint value is compared with the actual value.

The digital switching output D3 becomes active as soon as the divergence is

£ 0.5% FS and becomes inactive when the divergence > 1% FS is exceeded.

Graph for VPPM-...-...P switching variant

Fig. 6:

Switching variant VPPM-...-...P

Setpoint value

Actual value

Upper tolerance limit

Lower tolerance limit

Graph for VPPM-...-...N switching variant

Fig. 7:

Switching variant VPPM-...-...N

Setpoint value

Actual value

Upper tolerance limit

Lower tolerance limit

Circuit diagram VPPM-...-...P Circuit diagram VPPM-...-...N

Tab. 4:

VPPM-... circuit diagrams Switching output

8

Commissioning

•

Keep high-frequency radiation away from the VPPM-... in order to avoid

increased tolerances of the outlet pressure.

• The VPPM-... interprets setpoint signals that are less than 1% Full Scale (FS) as

0 V or 4 mA. In this case the working pressure is set to ambient pressure.

• At typical input values below 3.6 mA , the valve detects a cable break and the

last pressure set remains unregulated. Leakage results in a change of pressure

over the long term.

1. Connect the VPPM-... with a setpoint value signal. The VPPM-... has a differen-

tial input. Apply the setpoint signal 0 … 10 V or 4 … 20 mA to contacts 3 and 4.

Apply the lower potential to contact 3 and the higher potential to contact 4.

Contact 3 (– setpoint value) can be connected to contact 7 (GND).

2. Power the VPPM-... with direct current.

– Supply voltage UV = 24 V DC ±10%

Select a parameter set for the regulator.

– Press and hold the [Edit] key for 3 seconds.

–

Select a parameter set with the [UP] and [DOWN] keys. The LED of the

selected parameter set lights up.

– Press the [Edit] key to confirm the selection.

The control response of the VPPM-... can also be set by remote control via

digital inputs D1 and D2.

Parameter set Control response Input D1 (PIN

1)

Input D2 (PIN

5)

1 Fast control response 1 (24 V DC) 0 (0 V DC)

2 Factory setting: universal control

response

0 1

3 Precise control response 1 1

Tab. 5: Parameter sets

The following 3 tables show the recommended parameter sets for the different

pneumatic ports:

Parameter sets recommended for VPPM-6...

Tube length

1)

Open system Output volume in ml

0 … 100 100 … 1000 >1000

0 m 3 3 2 1

1 m 3 3 2 2

3 m 3 3 3 2

³ 5 m 3 3 3 2

1)

with inner tubing diameter 6 mm or 8 mm

Tab. 6: Parameter sets recommended for VPPM-6...

Parameter sets recommended for VPPM-8...

Tube length

1)

Open system Output volume in ml

0 … 500 500 … 2000 >2000

0 m 3 1 2 3

1 m 3 1 2 3

3 m 3 2 3 3

³ 5 m 3 3 3 3

1)

with tubing diameter 8 mm or 10 mm

Tab. 7: Parameter sets recommended for VPPM-8...

Parameter sets recommended for VPPM-12L-...

Tube length

1)

Open system Output volume in ml

0 … 2000 2000 … 10000 >10000

0 m 3 1 2 3

1 m 3 1 2 3

3 m 3 2 3 3

³ 5 m 3 3 3 3

1)

with tubing diameter 12 mm or 16 mm

Tab. 8: Parameter sets recommended for VPPM-12L-...

9 Maintenance

9.1 Disassembly

NOTICE

•

When switching off the VPPM.-..., first make sure that the setpoint value is set

to 0, then that the supply pressure and finally the supply voltage are switched

off.

Switch off the following energy sources:

– Operating voltage

–

Compressed air

2. Disconnect the connections from the device.

3.

Remove the device from the mounting surface or H-rail.

9.2

Cleaning

Switch off the following energy sources to clean the outside:

– Operating voltage

–

Compressed air

2. Clean the device on the outside with a soft cloth as required.

Loading...

Loading...