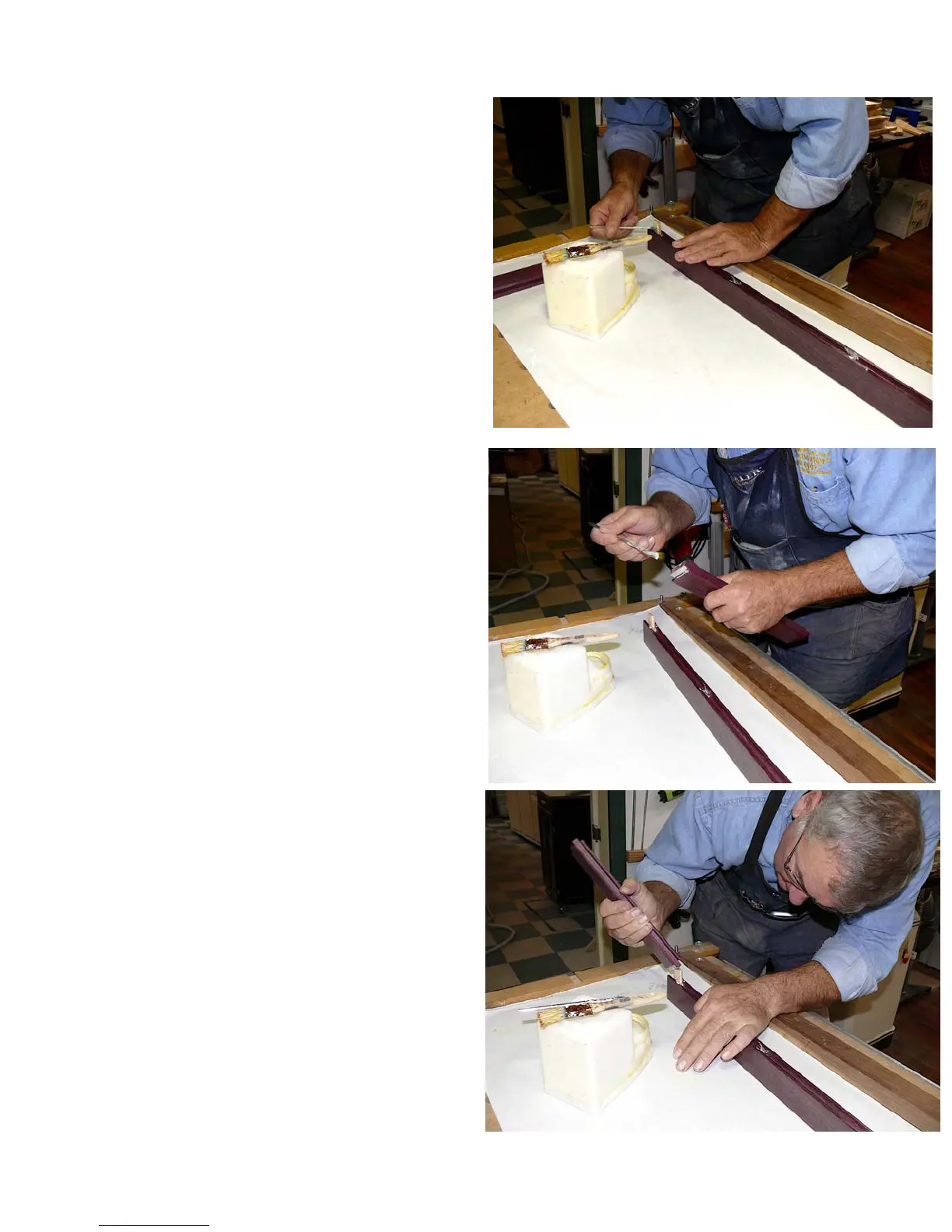

Now let’s construct the rail, stile and ma-

ple burl back panel. The doors will be

done the same way. We saw earlier how

I now use Domino M&T joints cut inside

the tongue and groove joints of the rail

and stile components to both reinforce

these joints and to make them self-

aligning.

With normal rail and stile construction

when you clamp up the assembly the rail

pieces with the tongues cut in their ends

can slide down the groove cut in the stile

pieces leaving the assembly either out of

square or with an unsightly gap between

the edge of the rail and the end of the

stile.

The Domino M&T eliminates that mis-

alignment by holding the edge of the rail

flush with the end of the stile speeding up

the whole process by much more than

the time required to cut the Domino mor-

tises in the first place. That is what I call

a real win-win.

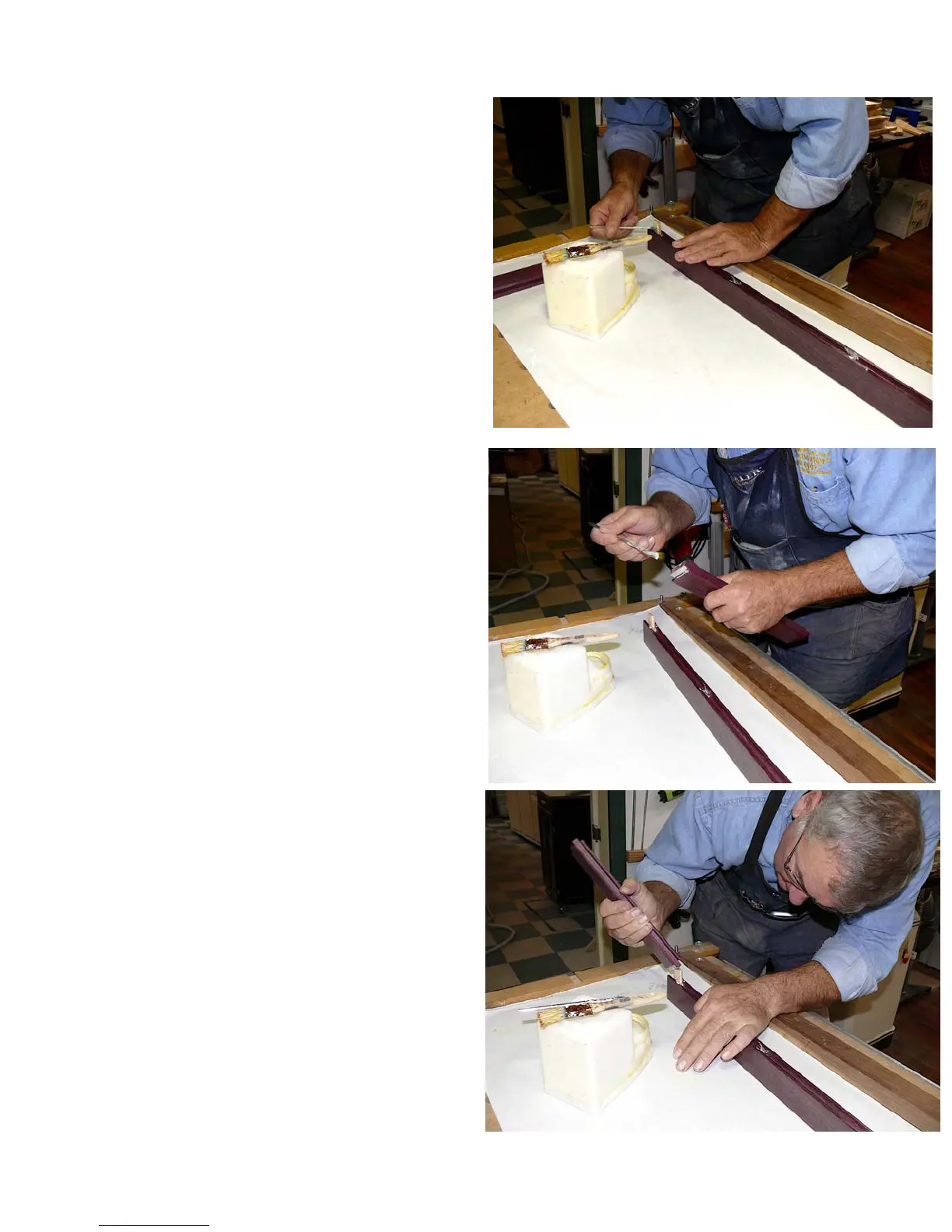

The same is true with respect to place-

ment of intermediate stiles as we will see

shortly on the back assembly for this

piece. Normally you have to measure

and mark the location for those and make

sure the intermediate stile stays in the

right place while you glue up and clamp

up. On many occasions that turns out to

be quite a time consuming process.

Well, watch here while the back rail, stile

and panel components go together. The

Domino M&Ts keep it all aligned without

me having to do anything.

While this would not necessarily be

true for everyone, I can justify the cost

of the Domino machine for this one

reason alone!

Loading...

Loading...