13

machine is used as intended (reasonable contact

pressure), a constant sanding speed is achieved.

Setting and adjusting the speed

The speed can be set

[1-5]

between 6000 and

10000 min

-1

using the adjusting wheel.

For sanding, we recommend the following settings

for the adjusting wheel

[1-5]

:

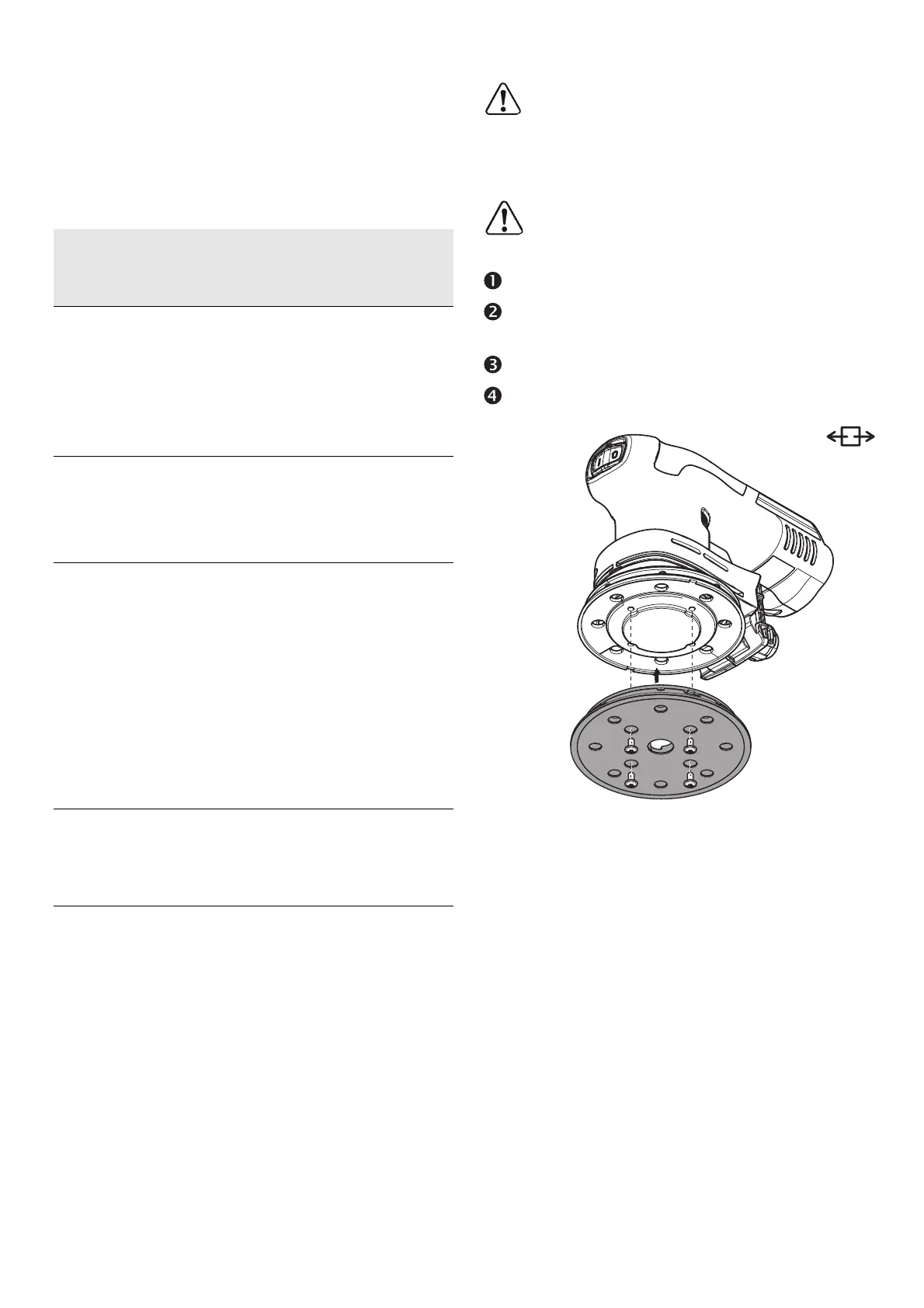

Replacing the sanding pad [4a]

An optimal work result can only be achieved

using original accessories and consumables.

The use of non-original accessories or con-

sumables invalidates the right to claim under war-

ranty.

Warning!

Do not perform any structural

changes in the open interior space of the ma-

chine when the sanding pad is dismantled.

Undo the four screws.

Remove the sanding pad by pulling it down-

wards.

Attach the new sanding pad.

Use four screws to tighten it by hand (2.5 Nm).

Sanding work Adjusting

wheel set-

ting

– Sanding with max. abrasion

– Sanding off old paint

– Sanding of wood and veneered surface

prior to paintwork

– Intermediate sanding of paintwork on sur-

faces

5 - 6

– Sanding thinly applied undercoat

– Sanding wood with sanding cloth

– Edge breaking on wooden parts

– Smoothing primed wooden surfaces

4 - 5

– Sanding solid wood and veneered edges

– Sanding rebate of windows and doors

– Intermediate sanding of paintwork at edg-

es

– Light sanding of natural wood windows

using sanding cloth

– Smoothing wooden surfaces using sand-

ing cloth before staining

– Rubbing or removing excess limestone

residue using sanding cloth

3 - 4

– Intermediate sanding of paintwork on

stained surfaces

– Cleaning natural wood window rebate us-

ing sanding cloth

2 - 3

– Sanding stained edges

– Sanding of thermoplastics

1 - 2

Loading...

Loading...