18 Rotex Series Dual Mode Sanders

Maintenance and Adjustment

WARNING! Any maintenance or repair work

that requires opening of the motor or gear hous-

ing should be carried out only by an authorized

Customer Service Center (see your dealer for

information on locating a service center).

WARNING! To reduce the risk of electrocution or

other personal injury, always unplug the tool from

the power supply outlet before performing any

maintenance or repair work on the tool.

NOTICE: Do not use compressed air to clean the

motor housing of the tool, as you could inject for-

eign objects into the motor through the ventilation

openings.

NOTICE: Certain cleaning agents and solvents are

harmful to plastic parts. Some of these include, but

are not limited to: Gasoline, Acetone, Methyl Ethyl

Ketone (MEK), Carbonyl Chloride, cleaning solutions

containing Chlorine, Ammonia, and household clean-

ers containing Ammonia.

Routine Maintenance

Dust and debris from some materials can be extremely

abrasive and cause components within the sander to wear

prematurely. It is important to keep moving parts cleared of

abrasive dusts.

► As a general rule, keep the sander clean of all dust and

debris. Even soft-wood dust can be abrasive over time.

► Examine all moving parts for dust and debris.

► Sanding pads are considered a wear item and will need

to be replaced periodically. Replace the pad when it no

longer holds sanding disks in place.

Motor Brush Replacement

Motor brushes provide electricity to the spinning motor

armature, and will wear over time. The brushes are

designed to disconnect power to the motor when they have

warn beyond their usable life. If your sander stops working,

it is likely that the brushes have warn and need replace-

ment. Contact Festool for replacement brushes.

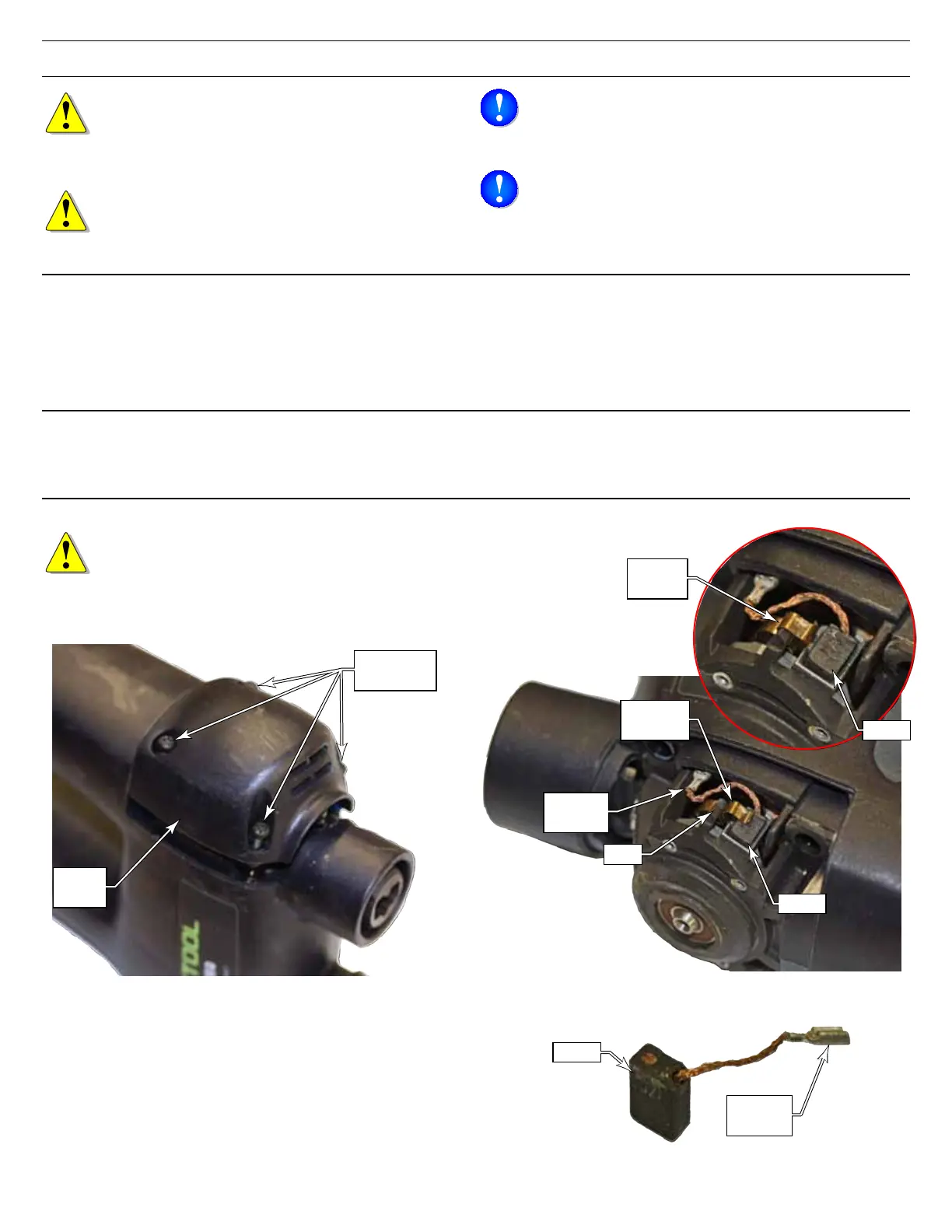

RO 90 Motor Brushes

WARNING! To avoid the risk of electrical shock,

make sure the sander is unplugged from power.

1. Unplug the sander from power.

2. Remove the 4 T10 Torx screws that secure the brush

cover, and remove the cover.

Brush

Cover

Mounting

Screws (4)

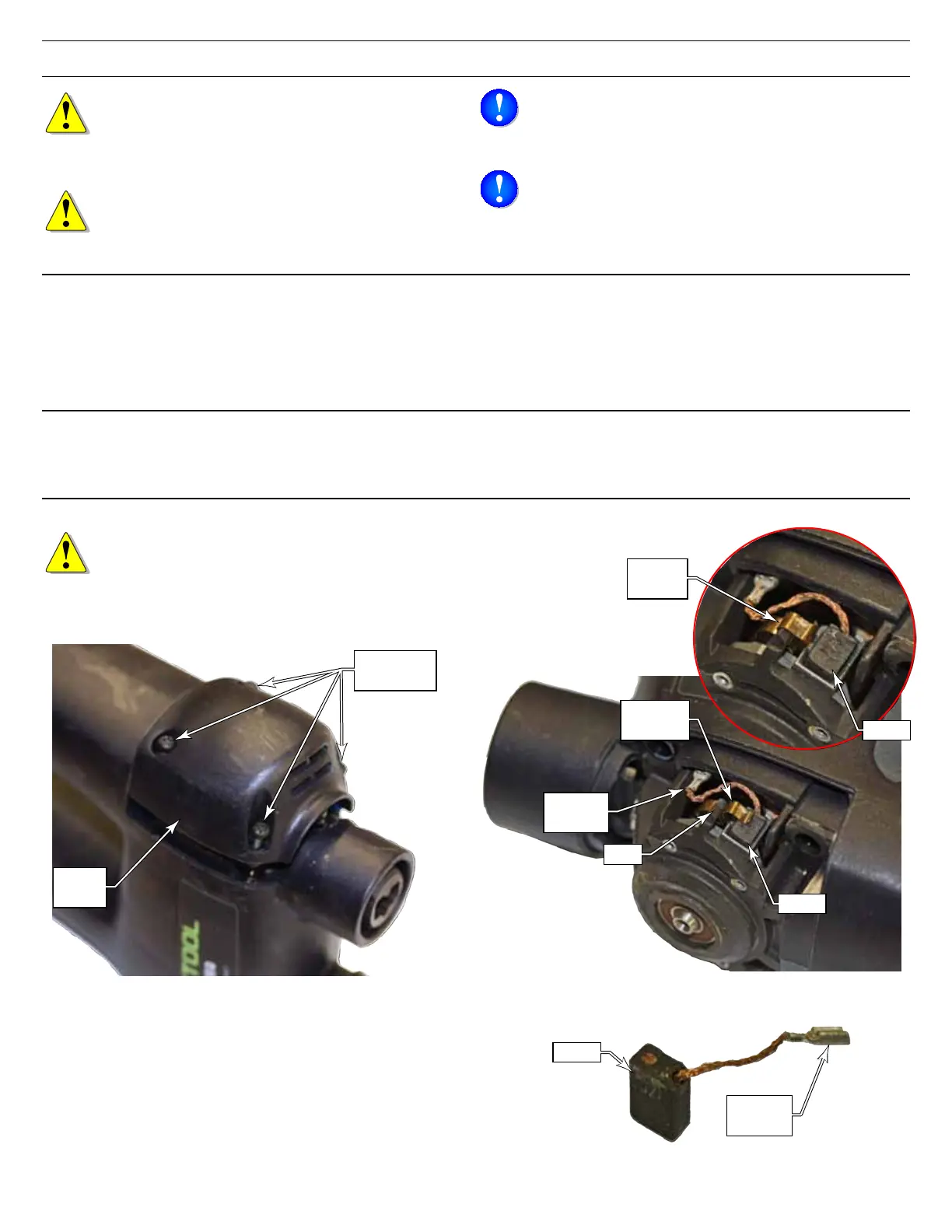

3. Using a small tweezer, carefully lift the pressure spring

off the brush and rest it on the adjacent post.

4. Using tweezers or needle nose pliers, carefully remove

the wire terminal from the spade lug.

5. Slide the brush out of the brush holder, and repeat for

the second brush on the other side of the motor.

Spring

on Post

Brush

Brush

Pressure

Spring

Post

Wire

Terminal

6. Install the new brushes by reversing the procedure. Don’t

forget to move the pressure spring back over the brush.

Brush

Wire

Terminal

Loading...

Loading...