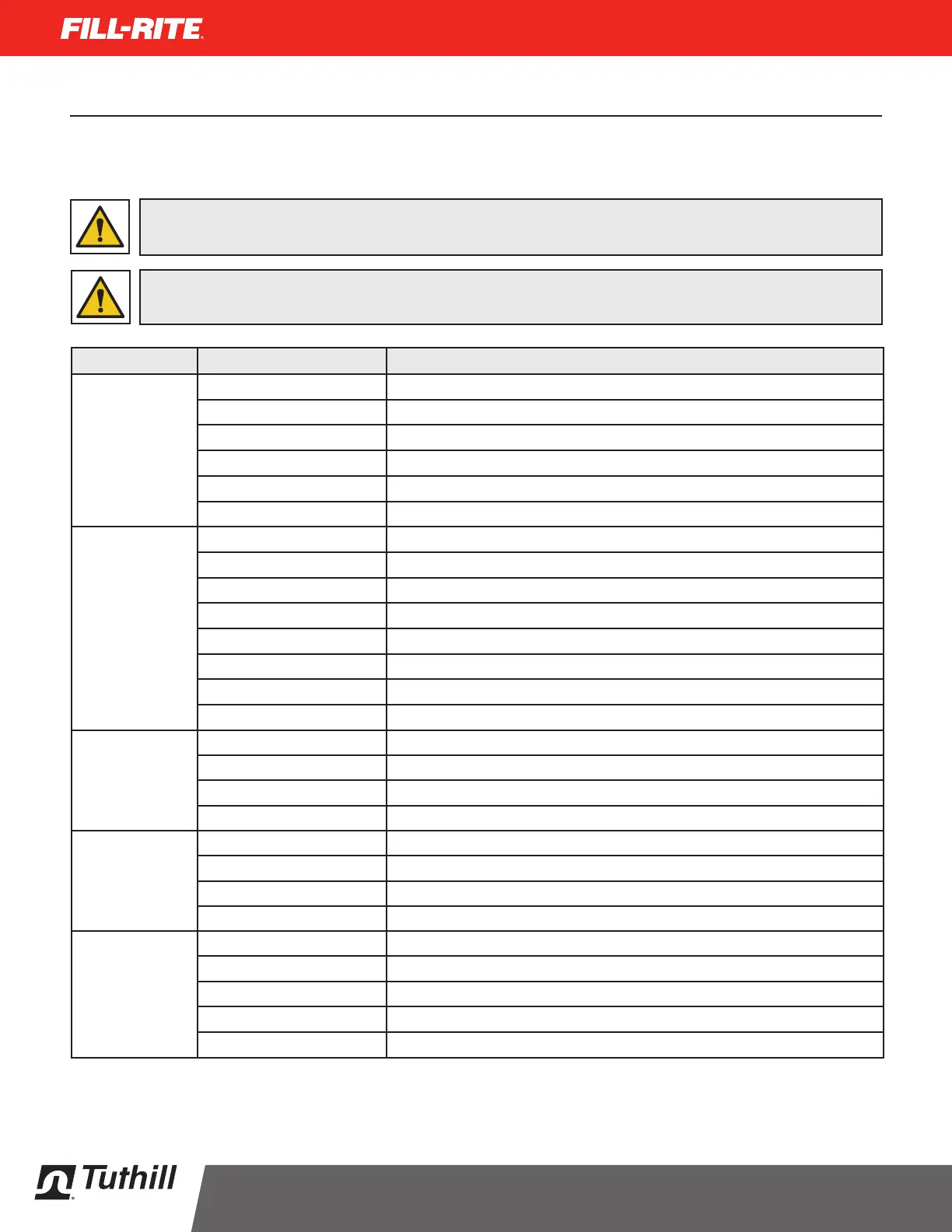

| FR3V SERIES FUEL TRANSFER PUMPS

WARNING! DO NOT open or attempt to repair the motor on your FR300V series pump. Opening the motor case can compromise the integrity of the Explosion Proof

construction and will void any existing warranty and certification (UL listing). Please refer to the warranty policy located on page 2.

WARNING! Be certain all power to the pump is turned off prior to performing any service or maintenance.

Symptom Cause Solution

Pump won't prime

1. Suction line problem Check for leaks in suction line.

2. Bypass valve open Remove and inspect valve, must move freely & be free of debris.

3. Vanes sticking Check vanes and slots for nicks, burrs and wear. *

4. Excessive rotor or vane wear Inspect rotor & vanes for excessive wear or damage, replace if necessary. *

5. Outlet blocked Check pump outlet, hose, nozzle & filter for blockage.

6. Vapor Lock Reduce vertical and horizontal distance from pump to liquid; Remove the automatic nozzle.

Low capacity

1. Excessive dirt Remove and clean screen.

2. Suction line problem Check suction line for leaks or restrictions; it may be too small, too long or not airtight.

3. Bypass valve sticking Remove and inspect valve; must move freely and be free of debris.

4. Vanes sticking Check vanes and slots of wear. *

5. Excessive rotor or vane wear Inspect rotor & vanes for excessive wear or damage; replace if necessary. *

6. Hose or nozzle damage Replace hose or nozzle.

7. Plugged filter Replace filter.

8. Low fluid level Fill tank.

Pump runs slowly

1. Incorrect voltage Check incoming line voltage while pump is running.

2. Vanes sticking Inspect vanes and slots for nicks, burrs and wear. *

3. Wiring problem Check for loose connections.

4. Motor problem Refer to warranty policy.

Motor stalls

1. Bypass valve sticking Remove and inspect valve, must move freely & be free of debris.

2. Low voltage Check incoming line voltage while pump is running.

3. Excessive rotor or vane wear Check rotor & vanes for excessive wear or damage. *

4. Debris in pump cavity Clean debris from pump cavity.

Motor overheats

(Thermal overload

tripped)

1. Pumping high viscosity fluids These fluids can only be pumped for short periods of time (less than 30 minutes duty cycle).

2. Clogged screen Remove and clean screen.

3. Restricted suction pipe Remove and clean pipe.

4. Motor failure Refer to warranty policy.

5. Pump rotor lock-up Clean and check pump rotor and vanes. *

Troubleshooting

The following Troubleshooting guide is provided to offer basic diagnostic assistance in the event you encounter abnormal service from your Tuthill product.

If you have questions regarding installing, operating, or servicing your product, please feel free to contact our Customer Service Department at 1-800-634-2695 (M-F 8 AM–6 PM ET).

You can also reach us on the World Wide Web at “www.fillrite.com”.

Loading...

Loading...