4

INSTALLATION

21

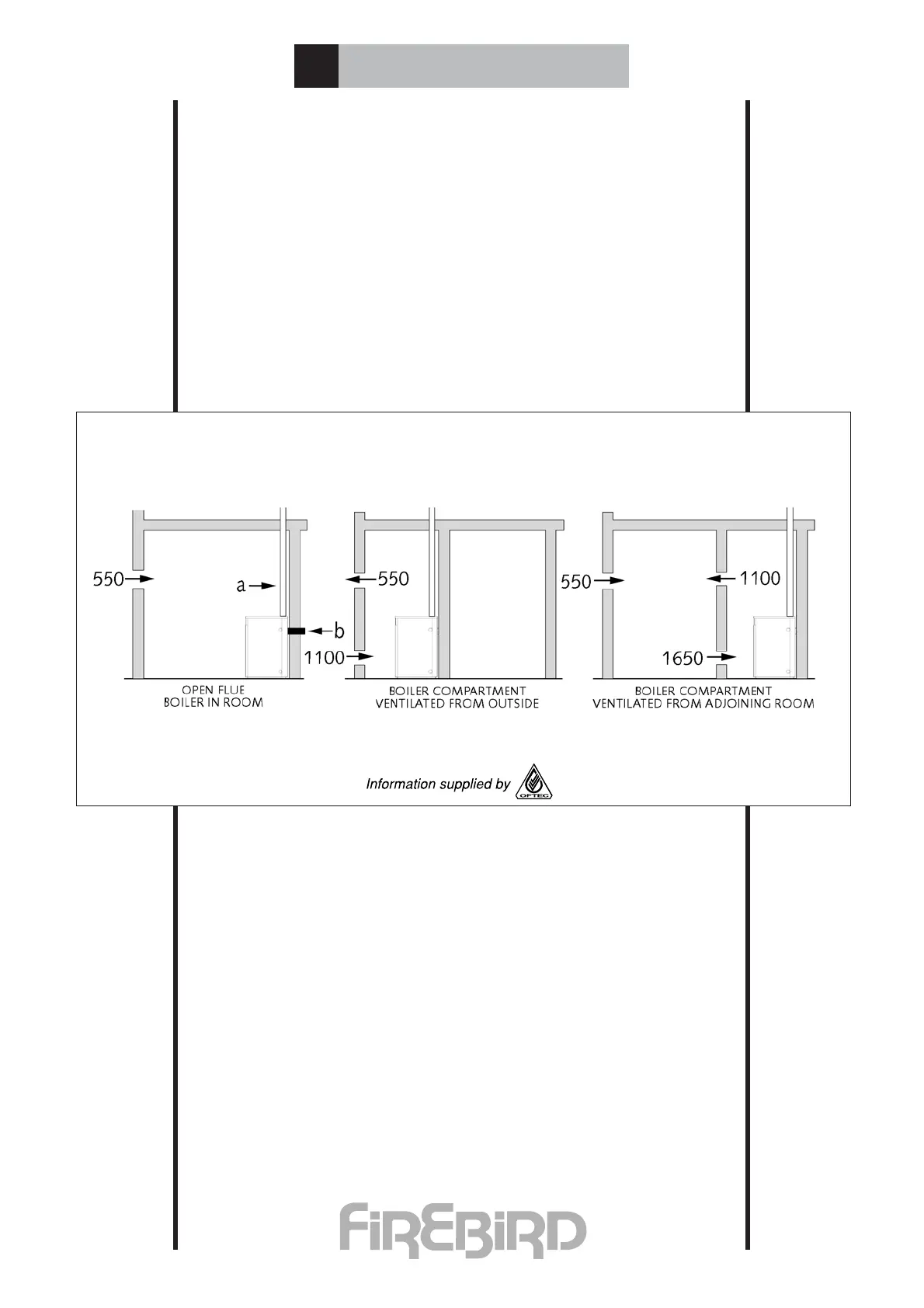

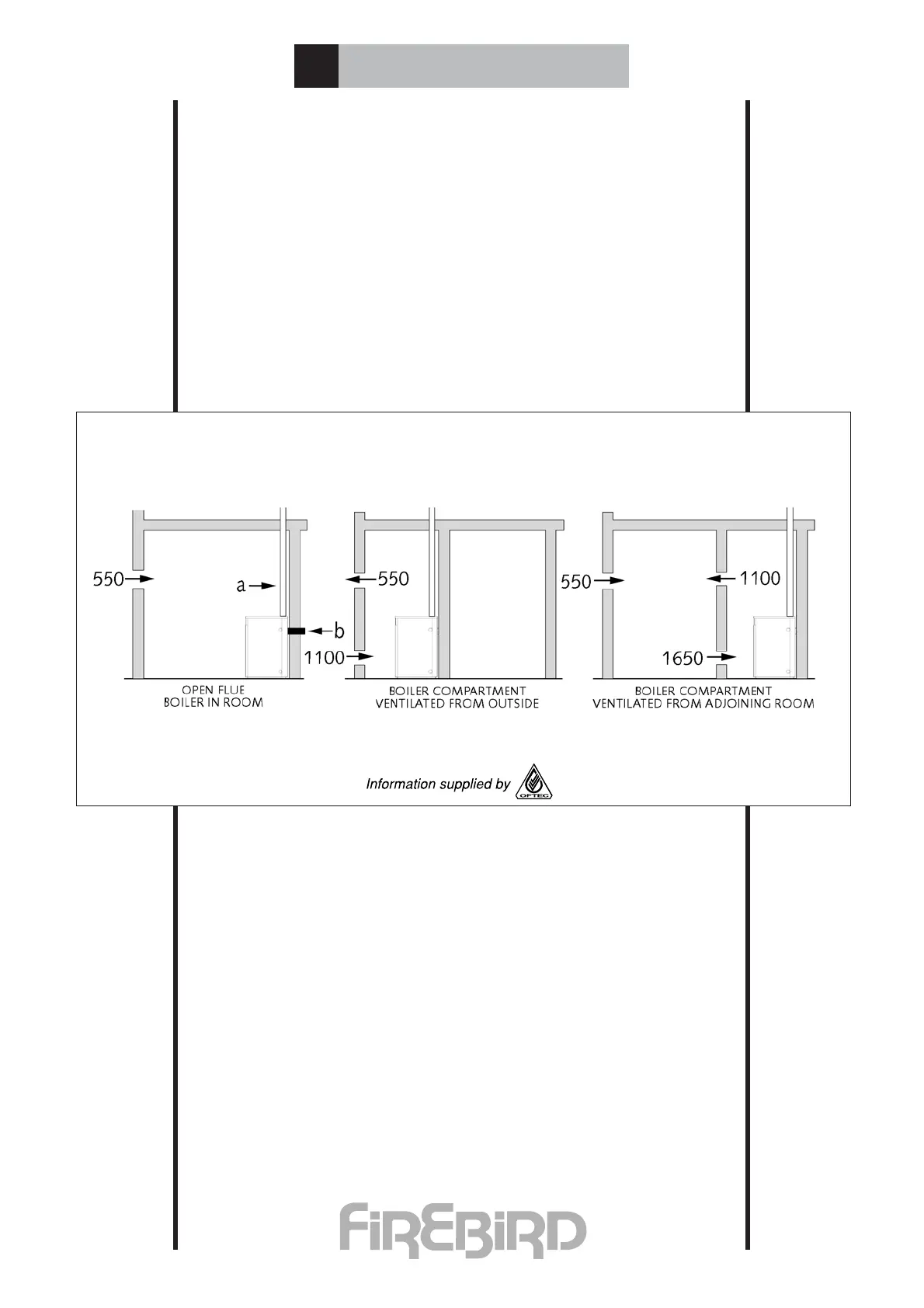

4-E Ventilation and Combustion Air

1. Conventional Flue Boilers

An adequate supply of combustion and ventilation air is essential for

efficient and safe boiler operation and the openings for this should be

positioned to cause least possible draught, with no possibility of being

accidentally blocked.

Please note: The British Standard Code of Practice for Oil Firing BS5410:

Part 1, requires a permanent air inlet opening of

550mm

2

per kW (above 5 kW)

of boiler rated output. (Note: 1kW = 3412 Btu/h).

Also, when the boiler is installed in a compartment or confined space,

ventilation openings are required to ventilate and to avoid overheating in

the boiler area.

FULL TEXT of both BS 5410 Part 1: 1997 and appropriate Building

Regulations for each country should be obtained and fully applied

N.B. Please Carefully Note:

A. For boiler installations in domestic garages in Scotland, Part F of

Building Regulations permits only Room Sealed appliances to be used (Ref.

OFTEC Bk. Three May 1999 page 1 (18).

B. Technical annex T1/127 to OFTEC Book Three, May 1999 page 2

(19) Para. 1, 2 states “In Scotland and the Republic of Ireland only Room

Sealed Balanced Flue Appliances can be used in that

location” (i.e. domestic garages).

Definitions

Combustion Air : Air required directly by boiler oil burner for combustion

process.

Ventilation Air : Air required in room for ventilation, cooling, etc. and to

promote a healthy living environment.

Conventional open flue (a) or open flue low level discharge (b)

Combustion & Ventilation air supply for conventional

open flue boilers

The figures shown are free areas of grilles in mm

2

per kw of appliance rating (output).

☛

☛

☛

☛

Loading...

Loading...