3 3.2 STANDARDS & REGULATIONS - FLUE SYSTEMS

9

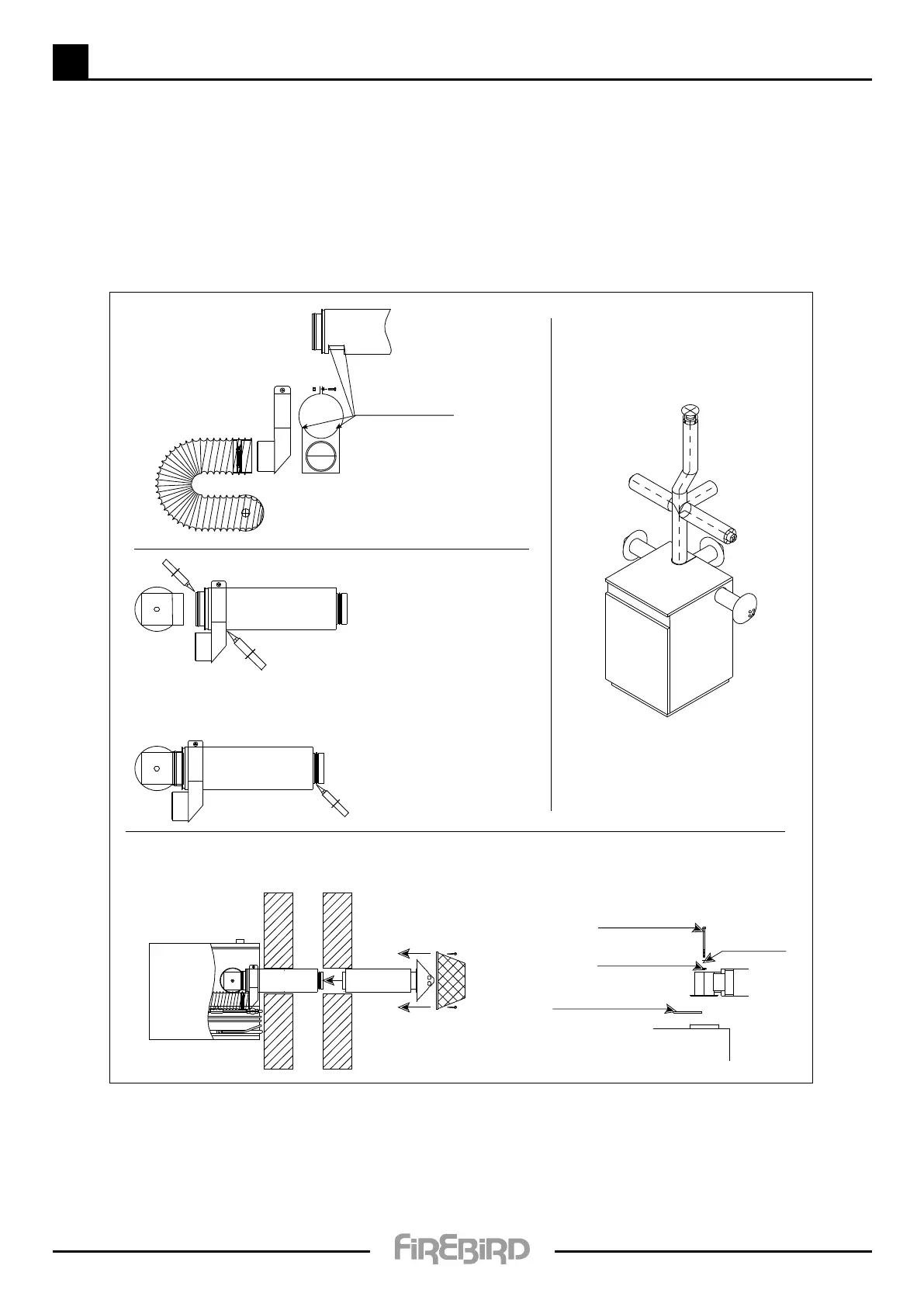

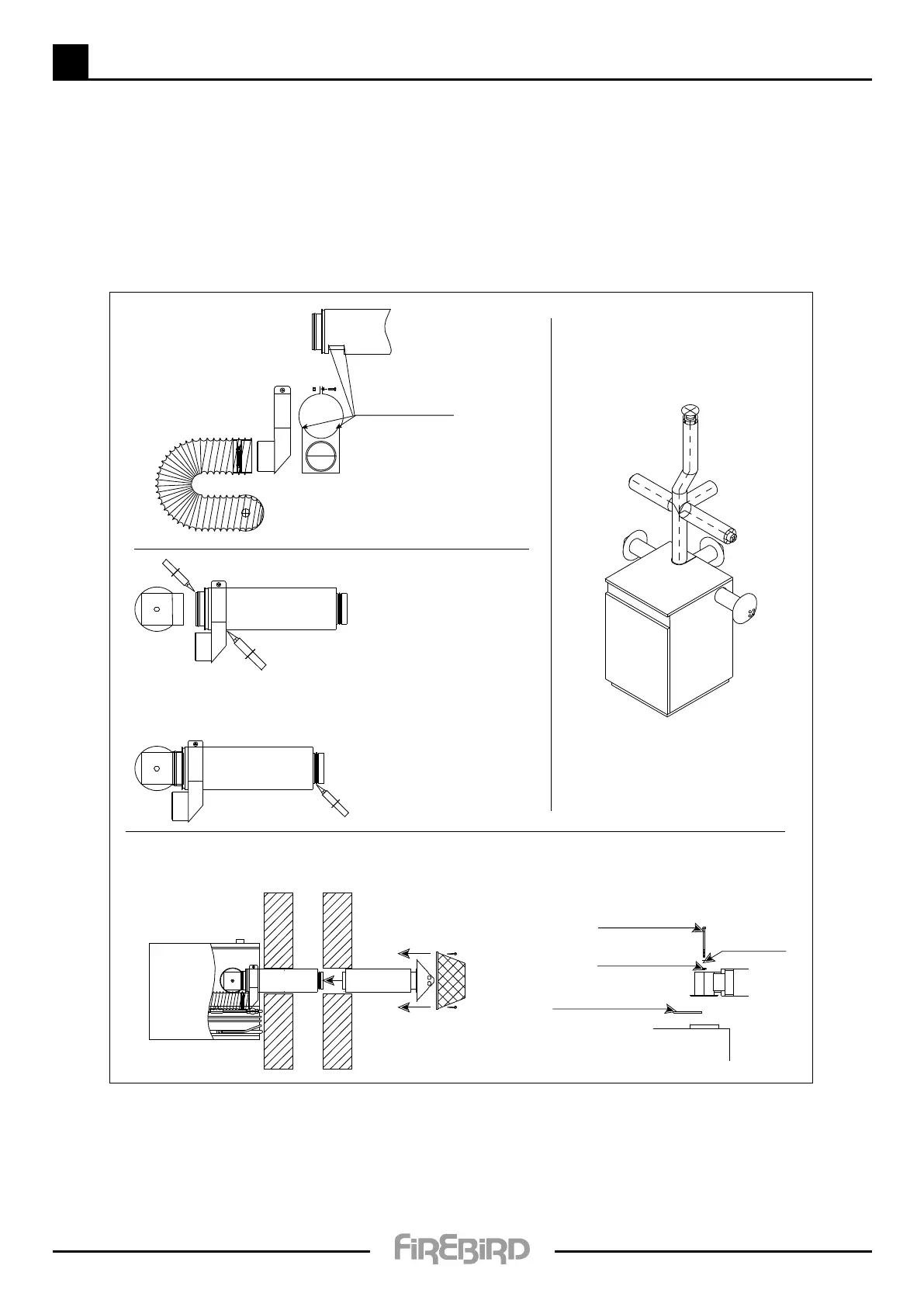

Balanced Flue System

IMPORTANT: THE INSTALLER MUST EXAMINE THIS ILLUSTRATION

CAREFULLY BEFORE PROCEEDING WITH INSTALLATION.

• The Firebird low level concentric ue kit has been specically designed for Firebird’s indoor boilers.

The use of third party low level ue kits is not recommended and may affect its warranty.

Locating points for xing

air box to ue pipe.

Push the ue adaptor in

to ue collar.

Push the ue pipe through

the 125mm hole in the wall.

Secure the ue

adaptor to the

boiler.

Apply high temperature sealant

to the O ring on the inner ue

pipe to ensure a positive seal.

IMPORTANT:

A 50mm - (2inch) gap

must be left between the

cone cowl and the wall.

Ensure Combustion air pipe

protrudes beyond the outer

surface of the wall.

GAS GAS

GAS

GAS

GAS

GAS

M8 x 130mm bolt

M8 ber washer

Ceramic gasket seal

M8 washer

ENSURE UNRESTRICTED AIR-SUPPLY TO BOILER ROOM.

No further adjustments are required for adequate combustion-air supply.

Check burner operation when installation is completed.

Use burner Combustion Analyser to ensure correct performance.

Consult separate burner manual supplied with boiler.

High Level Balanced Flue:

• Right hand outlet.

• Left hand outlet.

• Rear outlet and top outlet.

Apply high temperature

sealant to the inside of

ue collar.

Balanced Flue:

• Right hand outlet.

• Left hand outlet.

• Rear outlet.

GAS

GAS

GAS

GAS

GAS

GAS

GAS

GASGAS

Loading...

Loading...