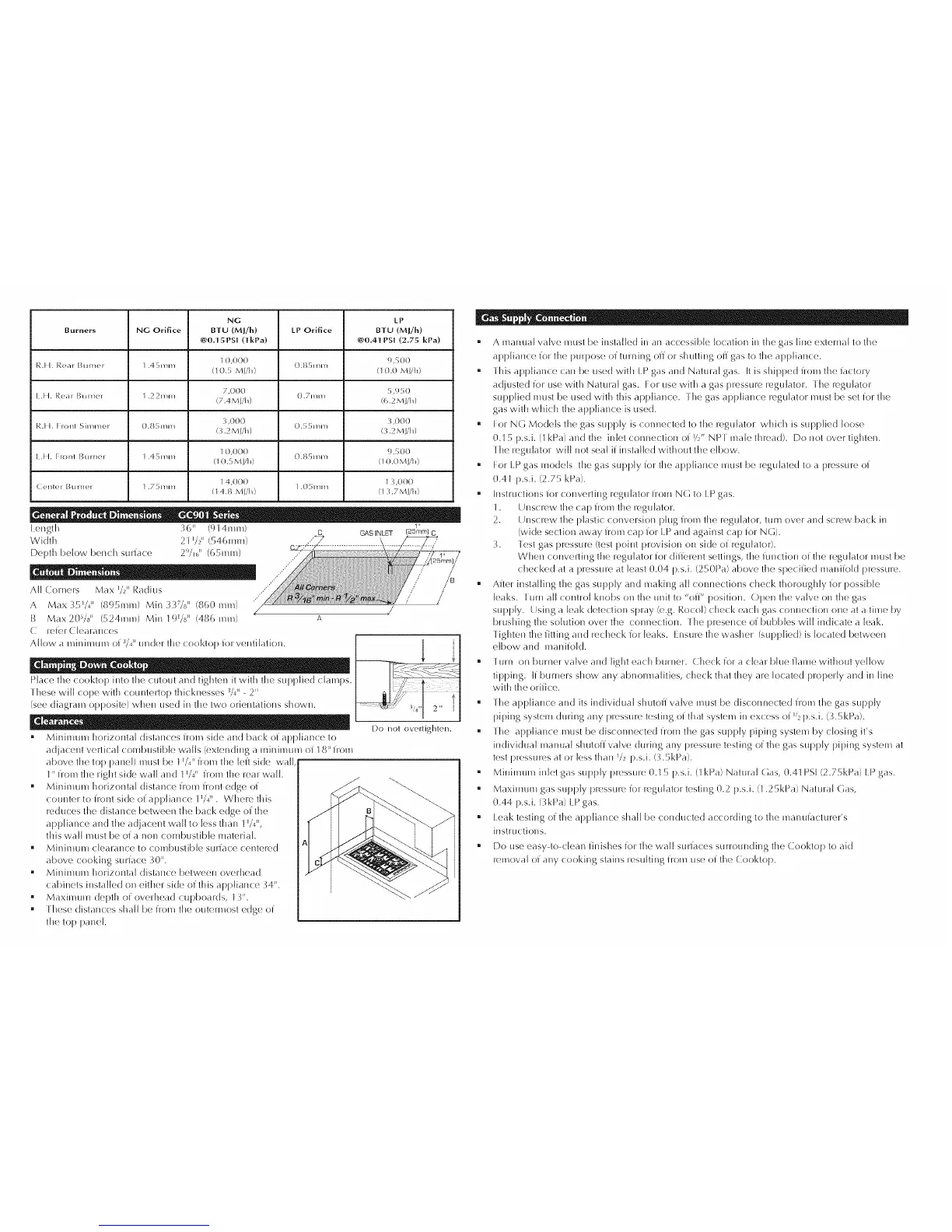

NG LP

Burners NG Orifice BTU (MJ/h) LP Orifice BTU (MJ/E)

@O.+15PSI (] kPa) @O.4+1 PSI (2.75 kPa)

JR.[ I. [',}ear Burner 1.45toni I 0,000 0.851_11_1 !),500

(I 0.5 Mj/h) (I 0.0 Mj/h)

I .I I. I',>ear Btllnel 1.22nlm 7,000 0.7me 5,950

(7.4M j/h) ff,.2Mjlh)

I',>.1 I. Fronl Sh11111c,I 0.8r;llln1 3,000 0 r r illn I 3,000

(3.2MWi9 (3.2 MWi9

I .I I. I IOlll l_tlfllOf 1,45111nl I 0,000 0,85111111 !),500

(l 0,', Ml/h) (l 0,0 Ml/h)

(2,nlcq [3tilnc,l 1.75mm I 4,000 1.05HI1_1 I 3,000

( t 4.8 Mj/h) (l 3.7Mj/h)

t ength g"o" (9 14me) 6ASINLTT s"

Width 21 _/2" (5461_Im)

DelJth below bench suriace 29/16I' (65me)

I D " 0

All COHIeFS Max _/2"Radius

A Max35W' (895mm) Min337/8 '' (860mm1

I:_ Max 2()s/d ' (524mm) Min I !)1/811 (486 I/ll/l) A

C rek'r (tearauces

Allow a minilllulll of 3/,€' under the cooktop ior ventilation.

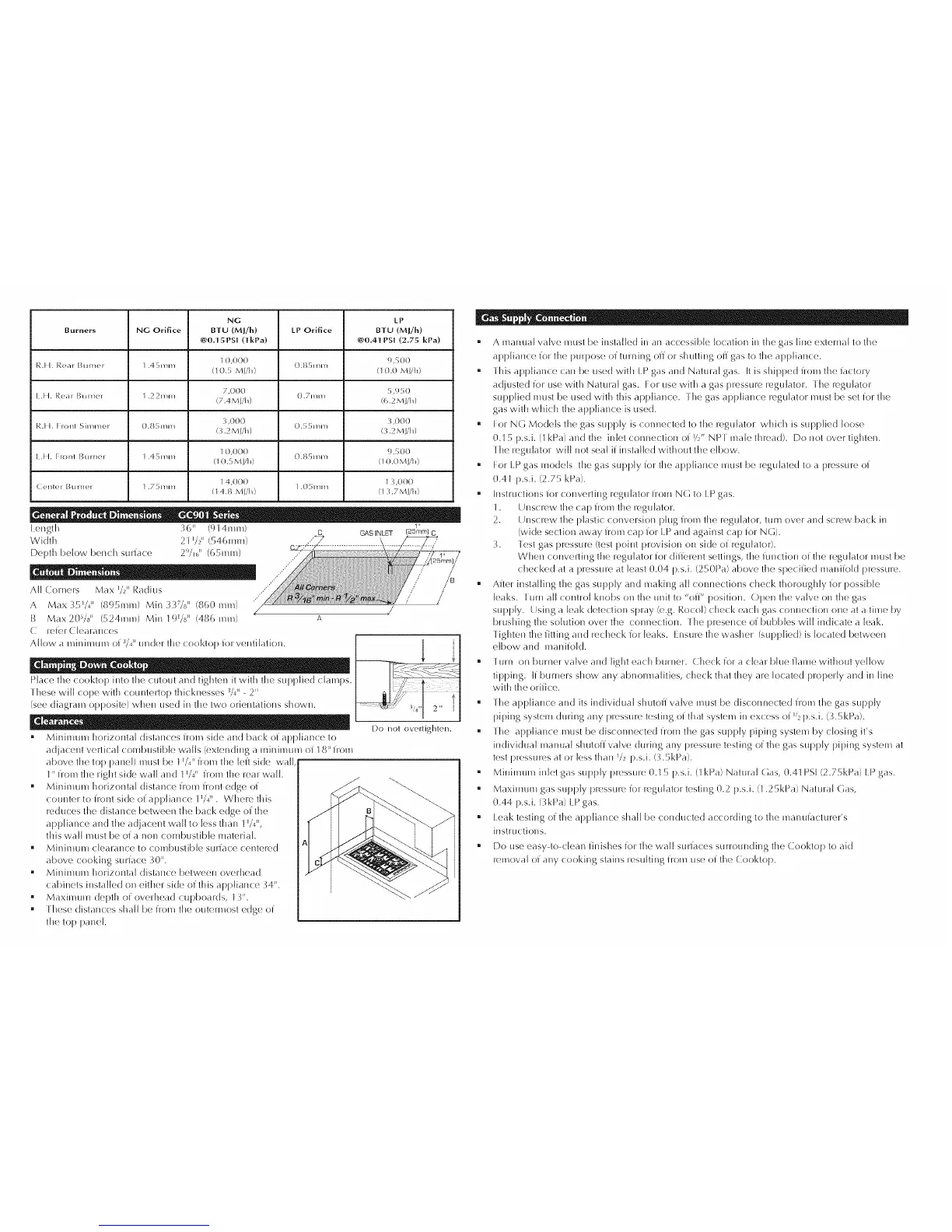

Place the cooktop into tile CtltO/lt and tighten it with the sUf)l}lied clamps.

these witt cope with countertop thickuesses 3/+ 11 2 I1

(see diagram opposite) when used in the two orientations shown.

• Minimum horizontal distances i/om side aud back of appliance to

adjacent vertical combustible walls (extendiug a rniuil'nUl'n of t 8IIirom

above the top panel) must be t _/,_"i/om the left side watt

t" irom tile right side watt and l I/311 i/Om the rear watt.

• Miniimml horizontal distauce irom flout edge ot

cotillter to i]ollt side el apIJtiauce I l/311 . Where tiffs

reduces tile (Jistance between tite back edge of the

appliance alld the adjacent watt to tess !halt t _/_",

this watt i'qtlst be of a non combustible material.

" Mininlul'n clearance to combustible suriace centered

above cookiug suriace 3()".

" MhlilllUm horizontal distauce betweelt overhead

cabiltets installed oil either side of this apptiaitce ")4".

• Maximum depth of ow_rhead cupboards, t +}".

• these distallces shall be irom the outerrnost edge of

the top panel.

Do not overtighten.

• A Illauuat valve I'nUSt be iustatted in all accessible location ilt the gels tiue external to the

appliance ior the purpose of turning offer shutting ofigas to the apptiallce.

• this appliance cau be tised witil t P gas an(J Natural gas. It is shipped from tile iactory

a(Jjuste(J ior use with Natural gas. For use with a gels pressure regulator, the regulator

supplied must be used with this apptiailce, the gels api}tiance regulator mtlst be set ior the

gels with which tile appliance is used.

• For NG Models tite gas supply is conuected to tile regulator which is supplied loose

0.t 5 p.s.i. (I kPa) an(J the inlet coitile(::tioll oi rZ," NP t male thread). Do not over tighten.

the regulator wilt ltOt seat ii installed without tile elbow.

• l:or t P gels models tile gels supply ior the appliance i'iltlst be regulated to a pressure of

0.41 p.s.i. (2.75 kPa).

• tustructions ior convertiug regulator i]om NG to t P gels.

t . t_JltsCI'OWthe celI) iroll} the regulator.

2. t Jltsorew !lie plastic OOlWersioll plug 7roe !lie regtltator, tttrn over and screw back ill

(wide section away 1]'O1"_I cap iOl t P alld against cap iOl" N(-]).

"). lest gels pressure (test point provision oil side oi: regulator).

When COliVertillg the regulator ior diiierellt settiugs, tile itlllctioll Of tile regulator must be

checked at a pressure at least 0.04 p.s.i. (250Pa) above the speciiied mauiiotd pressure.

• After ills!ailing the gels supply and making all connections check thoroughly ior possible

leaks, turn all control kuobs oil the unit to "off _' position. Open the valve oil tile gas

supply. Using a leak detection spray (e.g. Rocot) check each gas connection one at a time by

brushing tile solution over tile connection, the presence of bubbles wilt indicate a leak.

lighten the it!ring alld recheck ior leaks. Ensure the washer (supplied) is located between

elbow alld maliiiotd.

• [ urn oil burner valve aii(J light each buruer. Check iora clear blue itame without yellow

tif)piug, ti burilers show any abnorrnalities, check that they are located properly and ill line

witil the oriiice.

• the apiJtiauce and its iudividuat shutoi] valve i'iltlst be discollllected irol'_l the gas supply

pilling system during auy press!ire testing of that system iu excess of w2p.s.i. (+L5kPa).

• the apptiauce must be disconnected irol'_l tile gas supply pipiug system by ctosiug it's

iudividuat inanuat shutoff valve during any ioressure testing of the gas supply piping system at

test pressures at or tess thau _/2 p.s.i. (3.SkPa).

• Mininlum inlet gas supply pressure 0. t 5 p.s.i. (t kPa) Natural (]as, 0.4t PSi (2.75kPa) t P gas.

" Maxiinurn gas supply pressure ior regul<dor testing 0.2 p.s.i. (t .25kPa) Natural Gas,

0.44 p.s.i. (3kPa)t P gas.

• t eak testing el thc, apiJtiance shall be conducted according to tile rnanuiacturer's

instructions.

• Do use easy to clean iinishes ior tile watt SLII'iacos StlHOtllldillg the Cooktop to aid

retrieval of any cooking stains resulting froth use of tile Cooktop.

Loading...

Loading...