912 Series

R

2

Table 1. Specifications

AVAILABLE See table 2

CONFIGURA TIONS

BODY SIZES AND END Inlet: 1/4-inch NPT screwed

CONNECTION STYLES Outlet: J 1/4 or J 3/8-inch NPT

screwed

MAXIMUM 250 psig (17 bar)

ALLOW ABLE INLET

PRESSURE

OUTLET PRESSURE See table 2

RANGES

MAXIMUM Maximum Emergency Outlet

ALLOW ABLE OUTLET Pressure: 20 psig (1.4 bar)

PRESSURE Maximum Recommended Outlet

Pressure to Avoid Internal Part

Damage: 3 psi (0.21 bar, differ-

ential) above outlet pressure setting

INTERNAL RELIEF Approximate Internal Relief Valve

PERFORMANCE Start-to-Discharge Point: See

table 2

Capacity: Adequate only for relieving

minor buildup situations such as are

caused by chips or dirt blocking the

seat partly open; for major malfunctions,

external relief is required according to

the ‘‘Installation’’ section.

MA TERIAL -20 to 160_F (-29 to 71_C)

TEMPERA TURE

CAP ABILITIES

PRESSURE Internal

REGISTRA TION

APPROXIMA TE 1.3 pounds (0.6 kg)

WEIGHT

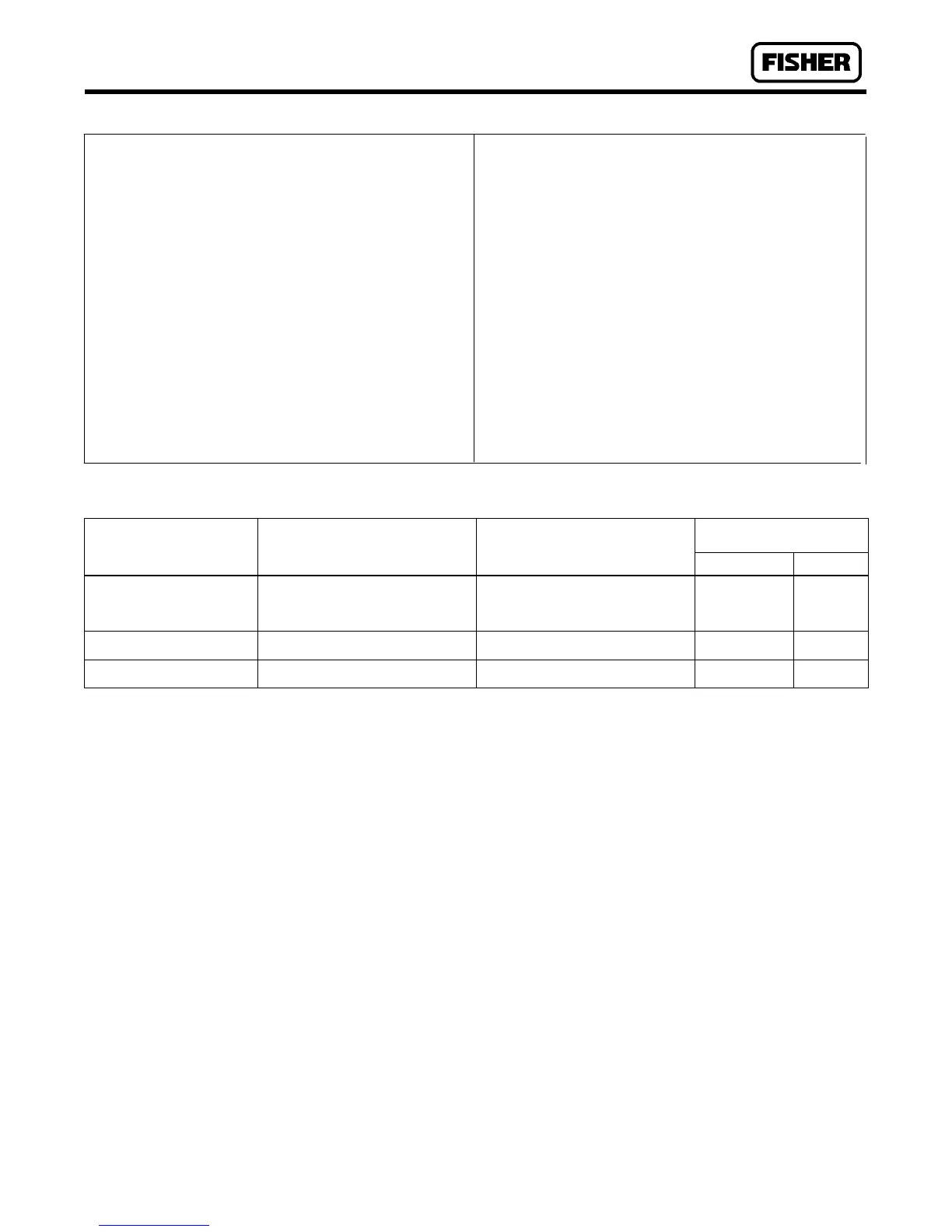

Table 2. Outlet Pressure Range Data

APPROXIMA TE POINT ABOVE

OUTLET PRESSURE SETTING

CONTROL SPRING

SELECTION

AT WHICH INTERNAL RELIEF

ST ARTS T O DISCHARGE

Part Number Color Code

Type 912 without handwheel

3 to 7 inches w.c. (7 to 17 mbar)

5 to 10 inches w.c. (12 to 25 mbar)

9.25 to 13 inches w.c. (23 to 32 mbar)

12 to 24 inches w.c. (30 to 60 mbar)

5 to 21 inches w.c. (12 to 52 mbar)

8 to 30 inches w.c. (20 to 75 mbar)

16 to 39 inches w.c. (40 to 97 mbar)

17 inches w.c. to 3 psig (42 to 210 mbar)

1B7843 27222

1B7844 27222

1L5079 37022

1B7845 27222

Red

Orange

Cadmium

Blue

Type 912H without handwheel

1 to 2.5 psig (69 to 172 mbar)

2.7 to 5 psig (186 to 340 mbar)

0.7 to 6.8 psig (0.05 to 0.47 bar)

3.8 to 12.5 psig (0.26 to 0.86 bar)

1B7846 27222

1B7847 27222

Yellow

Green

912 Series with handwheel

0 to 1 psig (0 to 69 mbar)

0 to 5 psig (0 to 340 mbar)

0 to 3 psig (0 to 210 mbar)

0 to 12.5 psig (0 to 0.86 bar)

1C5804 27222

1C5805 27012

Black

Brown

area. The vent opening on the regulator or the

opening on the remote vent pipe (if one is used)

should be pointed down to minimize clogging

from collected moisture, corrosive chemicals,

or other foreign material. Overpressuring the

downstream system (and risk of explosion)

could result from a clogged vent.

Overpressuring any portion of a regulator or

associated equipment may cause leakage, part

damage, or personal injury due to bursting of

pressure-containing parts or explosion of accu-

mulated gas.

Like most regulators, the 912 Series regulators have an out-

let pressure rating lower than the inlet pressure rating.

Downstream protection is required if the actual inlet pres-

sure can exceed the regulator outlet pressure rating or the

pressure rating of any downstream equipment.

Regulator operation within ratings does not preclude the

possibility of damage from external sources or from debris

in the lines. A regulator should be inspected for damage pe-

riodically and after any overpressure condition.

Ensure that the regulator is undamaged and contains no

foreign material. Install the regulator so that flow through it

leaves the outlet port (marked on the body). The regulator

may be installed in any position, however, the spring case

vent should be pointed down. Spring case/vent orientation

can be changed by rotating the spring case with respect to

the body.

For an indoor installation, if the regulator controls a gas that

is flammable or otherwise hazardous, a spring case with the

optional tapped vent should be used so that the exhaust can

be piped away. Provide protection on a remote vent by

installing a screened vent cap into the remote end of the

vent pipe. The vent should be pointed down.

Apply a good grade of pipe compound to the pipe threads

before making the connections. Install piping into the

1/4-inch NPT inlet connection and the 1/4-inch or 3/8-inch

NPT outlet connection.

Loading...

Loading...