6. As shown in Figure 3, run a supply pressure line

from the upstream pipeline to the restrictor inlet

(use 3/8 NPT outer diameter tubing or larger).

Install a Type 252 pilot supply lter upstream of the

restrictor, if needed, to keep the supply source

from clogging the restrictor or pilot. Inspect and

clean this lter regularly to make sure it has not

been plugged.

7. Install a downstream pressure control line (as

shown in the appropriate view of Figure 3) to the

pilot control line connection. Connect the other

end of the control line at a minimum of 8 to 10 pipe

diameters downstream of the regulator in a straight

run of pipe. Do not place a control line connection in

a turbulent area, such as in or directly downstream

of a swage or elbow. Signicant restrictions in the

control line can prevent proper pressure registration.

When using a hand valve, it should be a full ow

valve, such as a full port ball valve. With a

Type 161EBM or 161AYM pilot or a PRX Series

pilot, run a downstream exhaust bleed line to the

downstream bleed line connection in the pilot

body assembly.

8. Good piping practices usually require swaging up

to larger downstream piping to obtain reasonable

downstream uid velocity.

Wide-Open Monitor Installations

1. Follow the procedures in the All Installations section

and then continue with step 2 of this section.

2. Pilot supply for the downstream monitoring regulator

must be obtained between the two regulators as

s

hown in Figure 4. For sizing purposes, add the

minimum differential pressure for each regulator

together to establish the required pressure drop

across the station.

3. In a wide-open Type EZR monitoring system, system

lockup will be that of the worker regulator on both an

upstream monitor when the upstream pilot exhaust is

piped to the intermediate pressure and a downstream

monitor with upstream pilot exhaust piped to either

intermediate pressure or outlet pressure. With these

congurations, the diaphragm of the monitor regulator

will change position with every load change. On an

upstream monitor with the upstream pilot exhaust

piped to downstream, lockup will occur at the

monitor’s setpoint and the diaphragm of the monitor

regulator will be fully open during normal conditions.

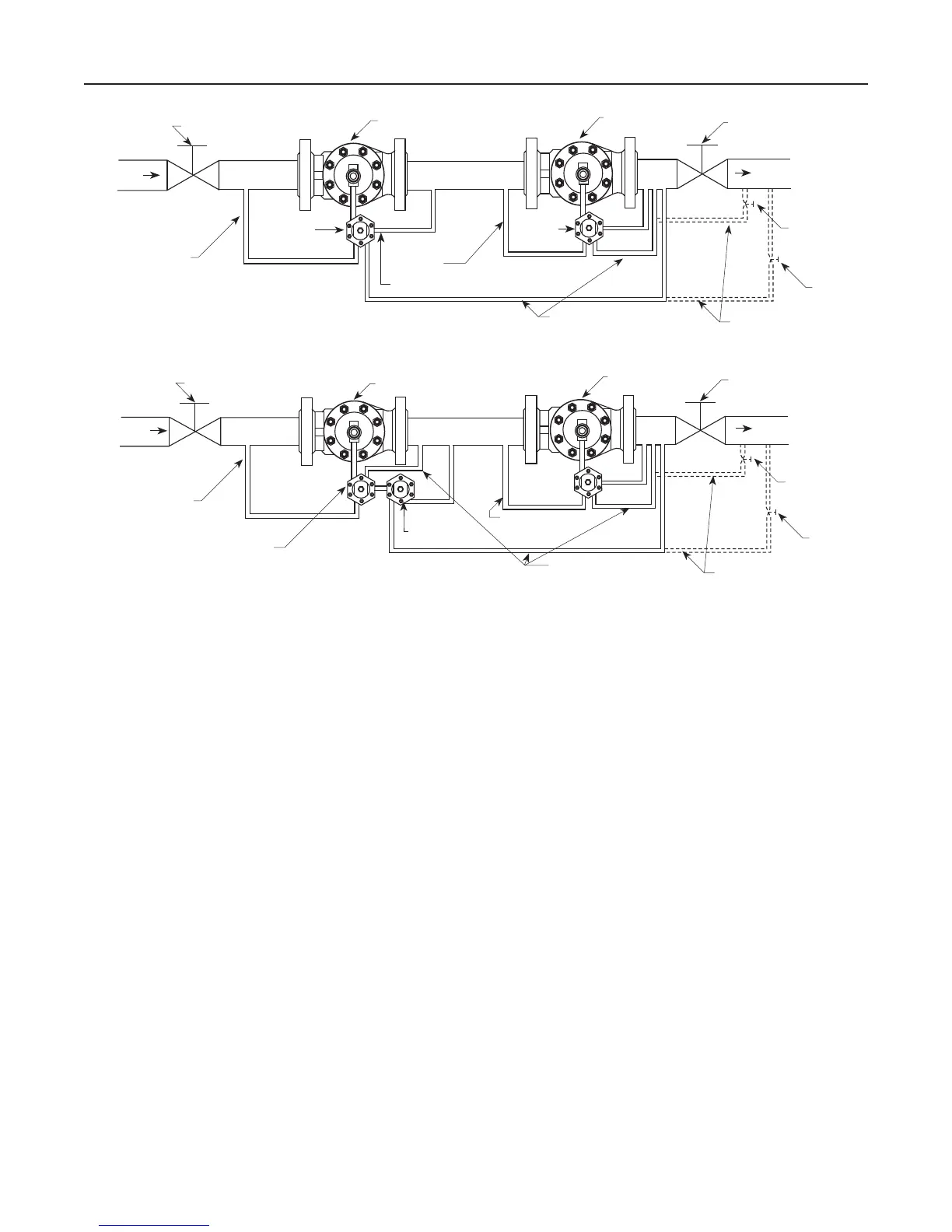

BLOCK VALVE

UPSTREAM REGULATOR

DOWNSTREAM

REGULATOR

BLOCK VALVE

OUTLET

INLET

SUPPLY

PRESSURE LINE

PILOT

EXHAUST

TYPE PRX

PILOT

SUPPLY

PRESSURE

LINE

TYPE PRX

PILOT

CONTROL LINE

ALTERNATE

CONTROL LINE

HAND

VALVE

HAND

VALVE

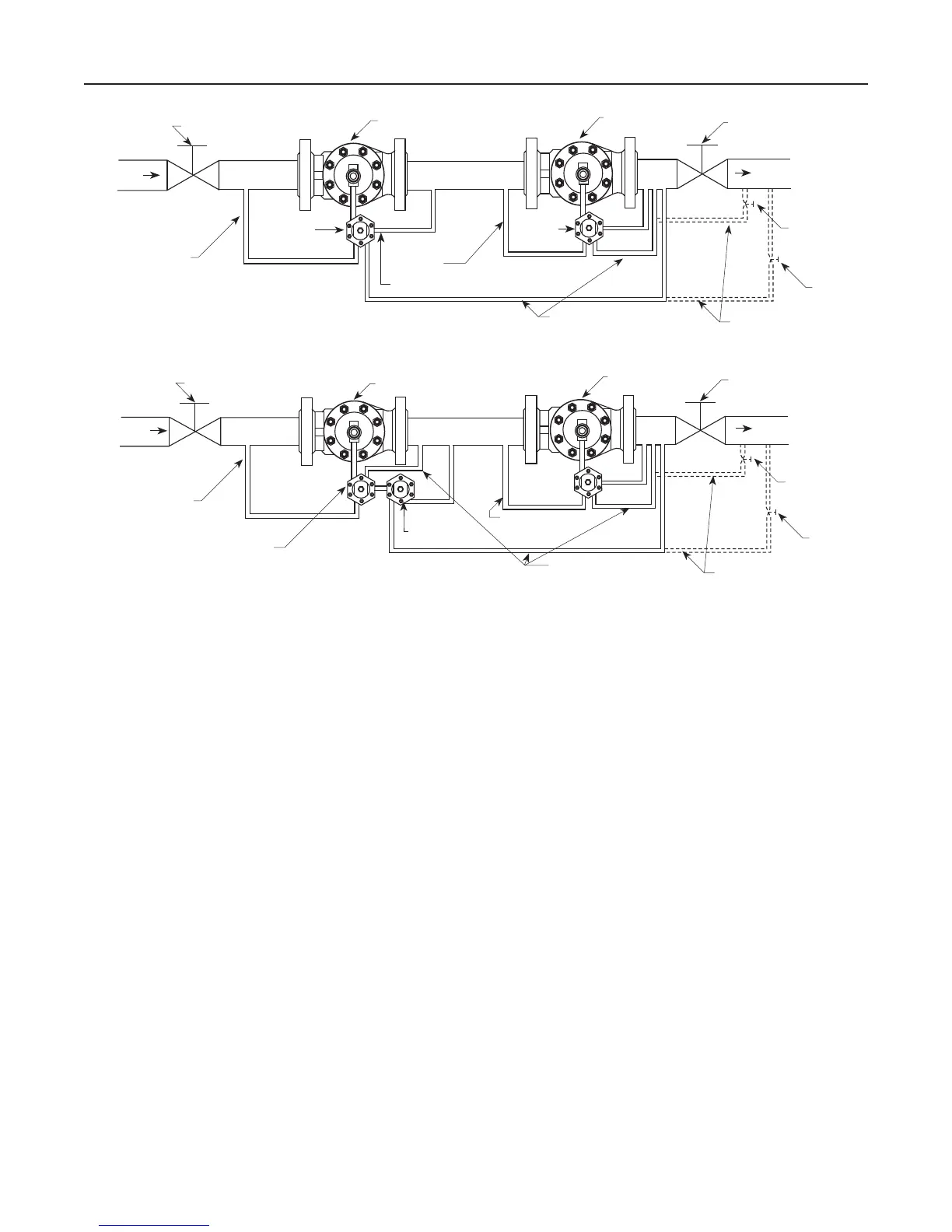

Figure 4. Typical Type EZR Monitoring System Installation Schematics (continued)

TYPE PRX WORKING MONITOR SYSTEM INSTALLATION

CONTROL LINE

TYPE PRX WIDE-OPEN MONITORING SYSTEM INSTALLATION WITH PILOT EXHAUST TO INTERMEDIATE PRESSURE

BLOCK VALVE

MONITOR REGULATOR

WORKING

REGULATOR

BLOCK VALVE

OUTLET

INLET

SUPPLY

PRESSURE LINE

TYPE PRX-120

WORKING PILOT

TYPE PRX-125

MONITOR PILOT

SUPPLY

PRESSURE

LINE

ALTERNATE

CONTROL LINE

HAND

VALVE

HAND

VALVE

L

(1)

L

A

A

S

S

B

B

(1) PLUGGED

9

Type EZR

Loading...

Loading...