Type 1008

2

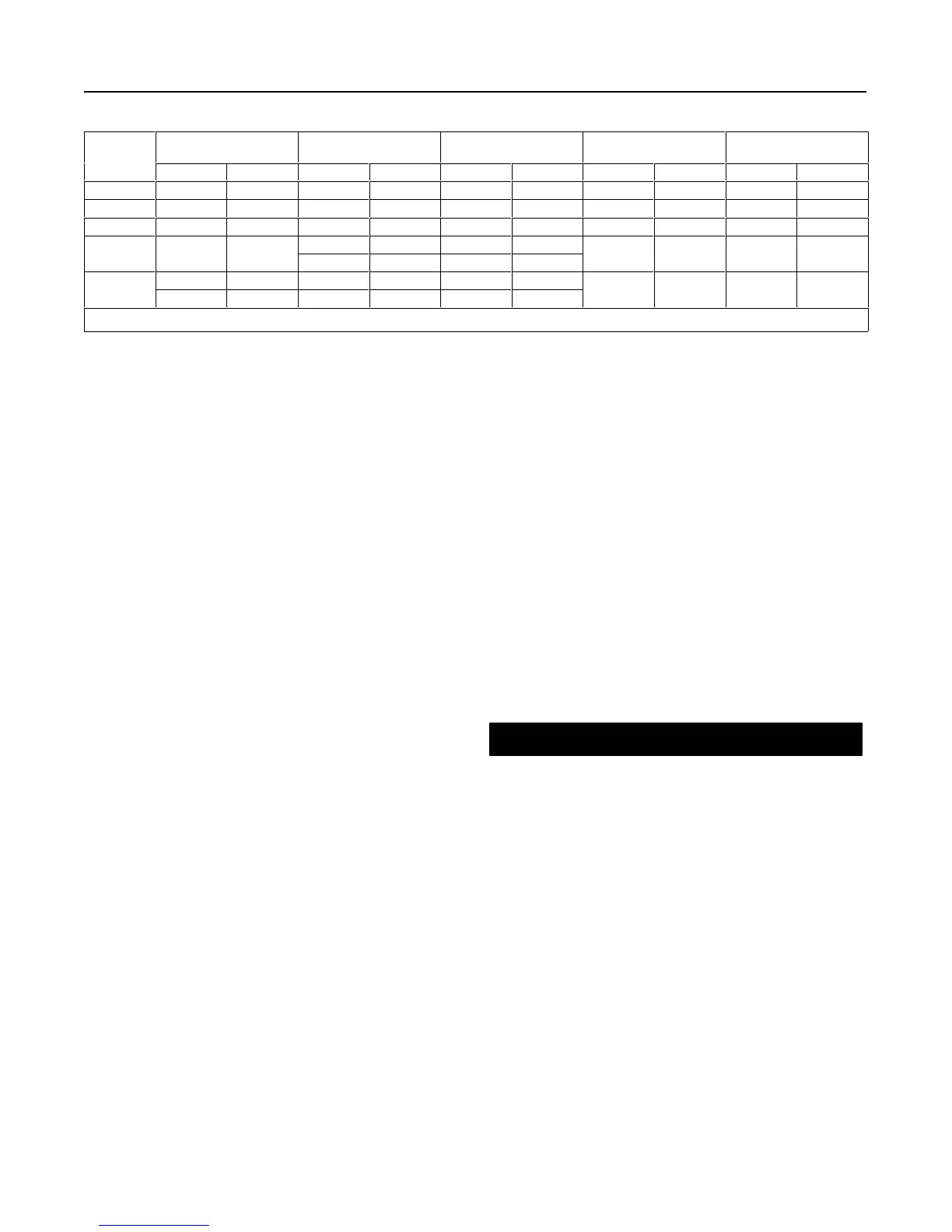

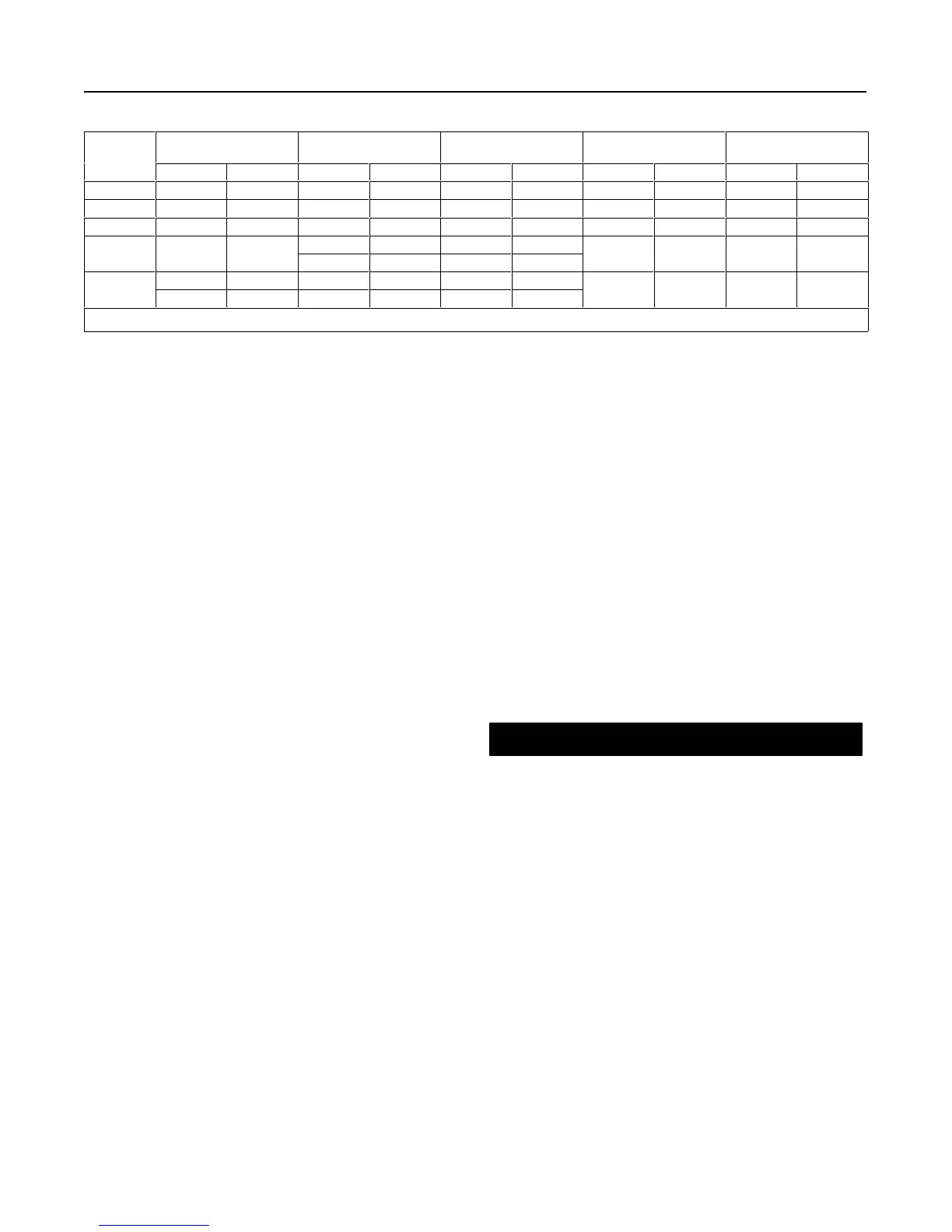

Table 1. Specifications

SIZE

YOKE BOSS

DIAMETER

STEM DIAMETER MAXIMUM STEM LOAD MAXIMUM TRAVEL

APPROXIMATE

WEIGHT

Inches mm Inches mm Pounds N Inches mm Pounds kg

30 2-1/8 54 3/8 10 1650

(1)

7340 3/4 19 15 6.8

40 2-13/16 71 1/2 13 2950

(1)

13,122 2 51 35 15.9

50 3-9/16 90 3/4 19 6650

(1)

29,581 4 102 45 20.4

1 25 11,250

(1)

50,042

80 5 127

1-1/4 32 17,000

(1,2)

75,620

3 76 100 45.4

5 127 1-1/4 32 17,000

(1,2)

75,620

100

7 178 2 51 56,000

(1,2)

251,004

4 102 150 68.0

1. For S31600 (316 stainless steel) stems at 100_F (38_C).

2. Actuator limit.

Specifications

Refer to table 1 for Specifications of the Type 1008

handwheel actuator. Refer to the actuator nameplate

for information about a specific actuator.

Installation

The Type 1008 handwheel actuator can be installed

horizontally, vertically, or at any orientation in be-

tween. However, if supplied with a Tejax position indi-

cator (see figure 6), the actuator must be installed in a

horizontal position.

When an actuator and valve body are shipped togeth-

er as a control valve assembly, the actuator is normal-

ly mounted on the valve. Follow the valve body

instructions when installing the control valve in the

pipeline. If the actuator is shipped separately or if it is

necessary to mount the actuator on the valve, perform

the Actuator Mounting procedures.

Actuator Mounting

Key numbers refer to figure 2 for size 30, figure 3 for

sizes 40 and 50, figure 4 for size 80 or figure 5 for size

100.

1. Place the actuator on the body bonnet and tighten

the yoke locknut or the actuator mounting hex nuts.

2. Ensure the valve plug is on its seat.

3. Adjust the travel indicator scale (key 27) so that the

two screws (key 19) are centered in the slots.

4. Screw the hex nuts (key 29) onto the valve plug

stem and place the travel indicator disk (key 20) onto

the stem above the hex nuts. Adjust the nuts until the

travel indicator disk (key 20) points to the closed posi-

tion on the scale.

5. Temporarily connect the valve plug stem to the

stem connector assembly (key 24) and tighten the cap

screws into the stem connector.

6. Use the handwheel (key 28) to move the valve plug

into the fully open position, as indicated by the travel

indicator disk (key 20) on the travel indicator scale

(key 27).

7. Remove the stem connector assembly (key 24).

8. Size 30: Turn the handwheel (key 28) counter-

clockwise until the stem connector assembly (key 24)

almost touches the top of the yoke;

Sizes 40, 50, and 80: Turn the handwheel (key 28)

counterclockwise as far as it will go;

Size 100: Turn the handwheel (key 28) counterclock-

wise (for push-down-to-close valves) or clockwise (for

push-down-to-open valves) as far as it will go.

CAUTION

Incomplete engagement of both valve

stem and stem screw assembly (key 38)

or size 100 power screw (key 5) in the

stem connector can result in stripped

threads or improper operation. Be sure

that the length of each stem clamped in

the stem connector is equal to or great-

er than the diameter of that stem.

9. Connect the valve plug stem to the stem connector

assembly (key 24). Ensure that the bottom of the stem

connector is touching or nearly touching the travel indi-

cator disk (key 20). Tighten the stem connector (key

24) cap screws and lock the hex nuts (key 29) against

the travel indicator disk (key 20) and stem connector.

10. Rotate the handwheel until the valve plug seats.

Adjust the travel indicator scale (key 27) with two

screws (key 19) so that the travel indicator disk (key

20) points to the closed position on the scale. Tighten

the two screws.

Loading...

Loading...