FLAMEFAST RESERVE THE RIGHT TO CHANGE PRODUCT SPECIFICATION WITHOUT PRIOR NOTICE GG_V3.00_OM_022024

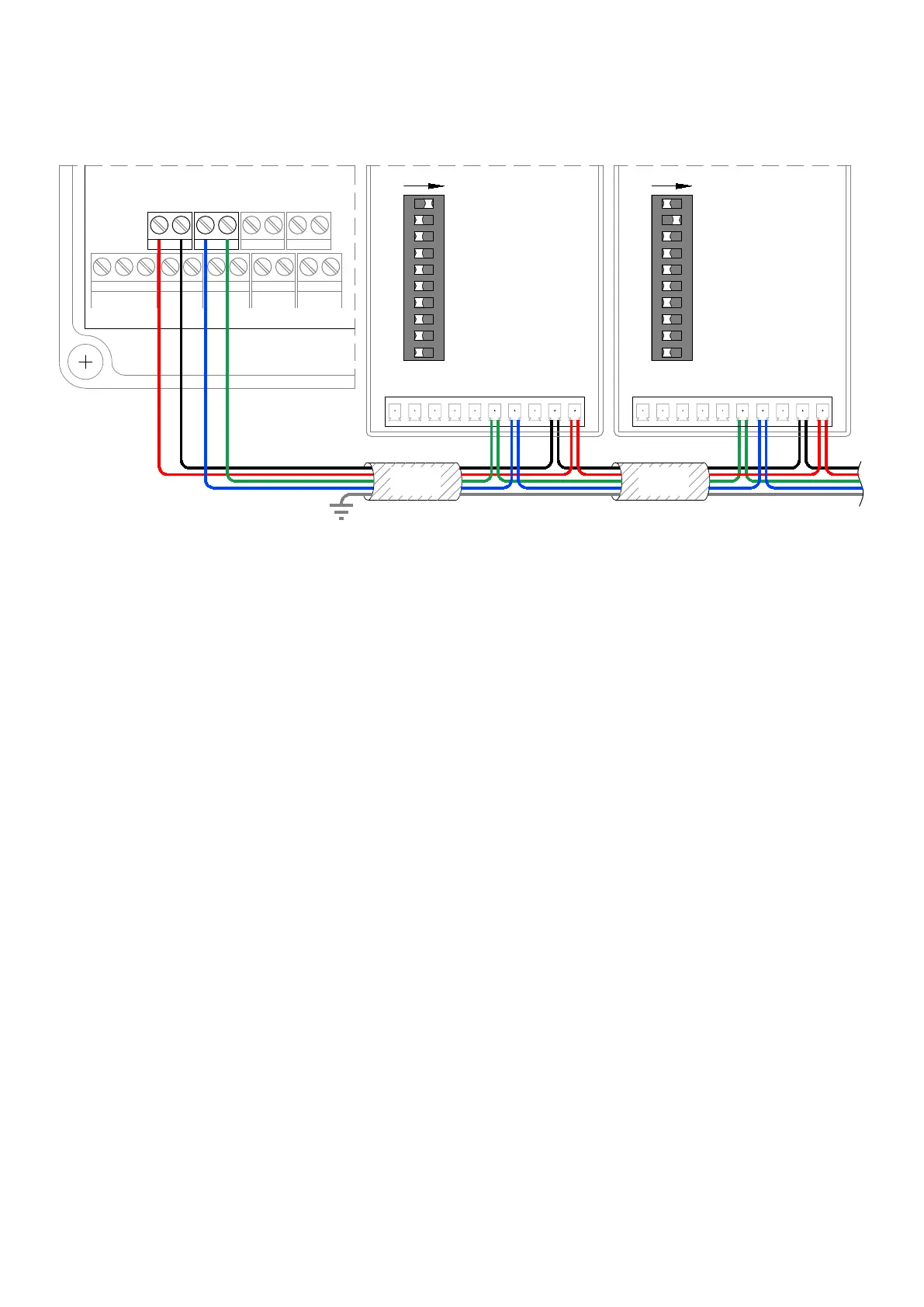

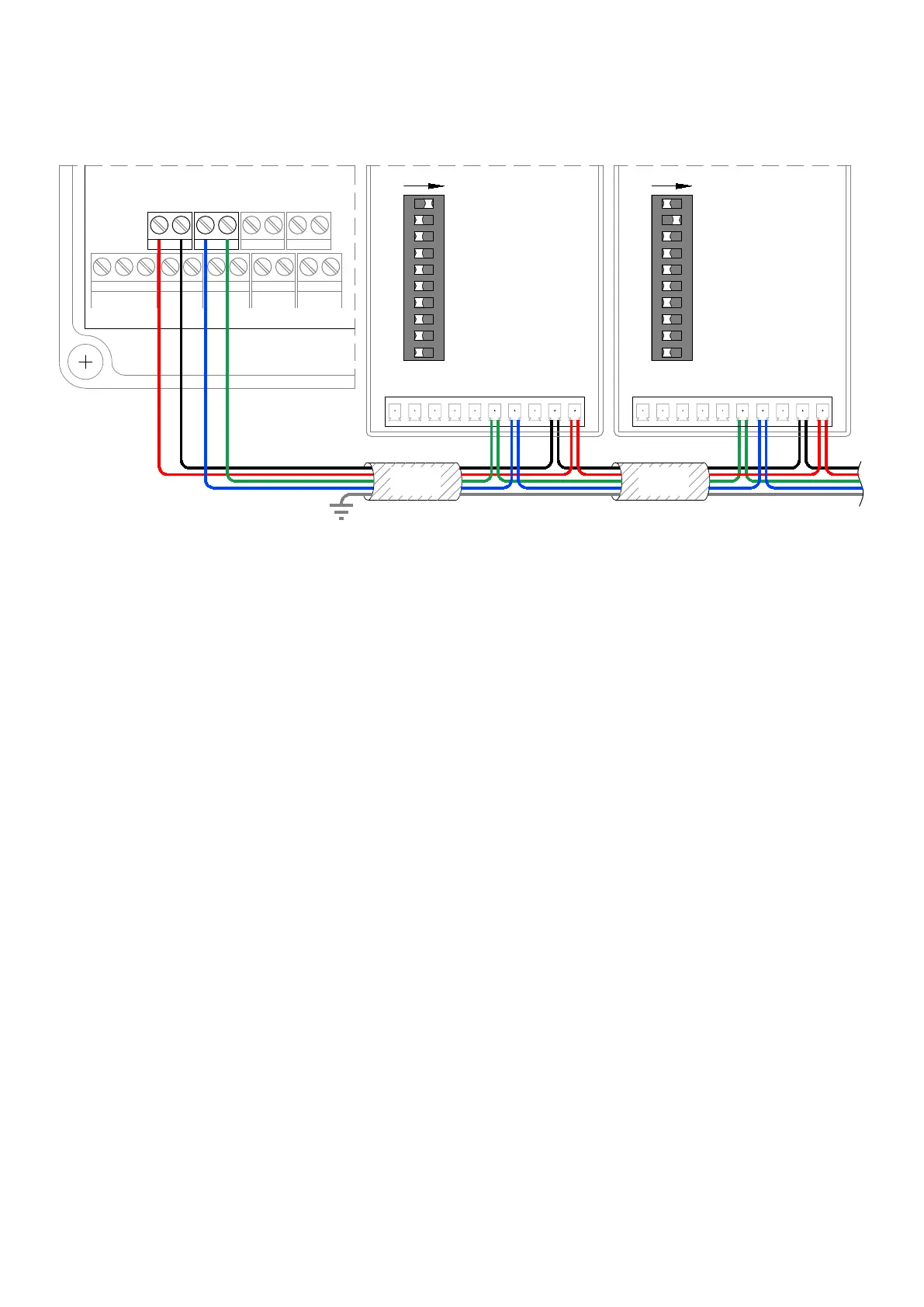

PLEASE SEE BELOW CONNECTIONS WHEN CONNECTING TO THE PANEL

SENSORS MUST BE WIRED IN ONE CONTINUOUS DAISY CHAIN. STAR WIRING CONFIGURATIONS MAY CAUSE THE PANEL TO ‘LOSE’ SENSORS

ALL SENSORS MUST BE SET TO DIFFERENT ADDRESSES, AND WE RECOMMEND NUMBERING STARTING AT 1, 2.. IN THE ORDER THEY ARE WIRED FROM THE PANEL

OPERATION & COMMISSIONING

GASGUARD

OPERATION

The basic operation of the system is advised by the LCD readout:

1. Turn the Key to ON to requested gas, which will initiate the pressure test.

a. The valve will open for 5 seconds to pressurise the pipework.

b. A pressure measurement will be taken.

c. The pressure will be monitored for a drop over 30 seconds.

d. If a pressure drop of more than 10% of the initial test pressure is

detected, the panel will alarm and advise.

e. If no pressure drop is detected, the panel will open the gas valve.

2. Turn the key to OFF to switch off the gas supply.

THE KEY SWITCH SHOULD BE TURNED TO THE OFF POSITION

AND THE KEY REMOVED WHEN THE ROOM IS UNOCCUPIED

COMMISSIONING

Once the installation is complete a functionality test must be carried out to verify

the correct installation & operation of the system – the gas must be live.

1. Turn the key switch to the ON position to ensure the gas valve output and

pressure transmitter are functioning correctly.

2. Press the panel mounted emergency stop button ensuring that all outputs are

isolated and the panel alarms accordingly.

3. Once all outputs have been proved, the gas proving function must be tested

by opening an outlet during the system test and ensure that the pressure drop

registers and the panel alarms accordingly.

4. The correct operation of any interfaced devices such as Remote Stop Buttons,

Intake/Extract Fans and Gas Sensors must also be verified.

PLEASE CONTACT FLAMEFAST FOR FURTHER DETAILS.

INTERNAL BUTTONS

ENGINEER button

The ENGINEER button on the main PCB can be used to aid with commissioning.

Providing the Remote Stop interface is not in alarm, holding this button then

turning the key switch will energise the Gas Valve and Status outputs to aid with

commissioning. This will timeout after 60 seconds unless switched off by the key

switch, after which the button will need to be released and held again for use.

Whilst the button is being held in, the unit counts to 60 and displays the gas

pressure.

LEARN Button

The LEARN button is for use when there are Gas Sensors connected to the unit.

Pressing this button will display the Channel, Gas Type, Reading and Days until

Calibration is required and Days until EOL. The unit will display 4 channels at a

time for 5 seconds each (20 seconds total display).

Following the connection/removal of any gas sensors, this button needs to be held

in for 30 seconds. At the end of the above mentioned 20 second status display,

the unit will countdown from 10 after which it will indicate how many sensors are

connected and store the data. This will then be used as a reference point to show

if any sensors go ‘missing’ at any point.

INTERROGATE Button

Holding the INTERROGATE button will display the status of ALL inputs along with

the gas pressure. This can be easily used to identify any faults. This will remain on

for 5 seconds following the release of the button, after which it will display the

number of days until a service is due.

24V

GAS

SENSOR

+ - A B

SCREENED

CABLE

SCR

C NC

RELAY

10V

0V 24V

AC/DC

B A

BACNET

RST

NO

SCR

C NC

RELAY

10V

0V 24V

AC/DC

B A

BACNET

RST

NO

ON

1

2

4

8

16

32

64

B1

B2

EOL

SCREENED

CABLE

ADDRESS GAS SENSORS

USING CHANNELS 1-16 ONLY

(SEE FGS/FGD MANUAL FOR

FURTHER DETAILS)

PANEL

FGS/FGD No.1 FGS/FGD No.2

12 13

14 15

ADDRESS GAS SENSORS

USING CHANNELS 1-16 ONLY

(SEE FGS/FGD MANUAL FOR

FURTHER DETAILS)

ON

1

2

4

8

16

32

64

B1

B2

EOL

Loading...

Loading...