910-0001-00-INS -R02 Page 47 of 53

Information contained in this document pertains to a Canadian origin product that is controlled as "dual use" by the Canadian

government. However, when in the United States or possessed by a US person, it may be considered a defense article from the US Government's

perspective. US government authorization may be required for re-transfer to a foreign person. If you have any questions, please contact FLIR's

Global Trade Compliance group at exportquestions@flir.com .

7 MAINTENANCE

7.1 VISUAL INSPECTION

Due to the critical nature of perimeter surveillance applications, it is of paramount importance to keep

the radar units trouble-free by routinely conducting visual verifications. The visual verification must

check the following:

• Verify that the radome is clear from any obstruction such as trees or branches or any natural

formation of dirt, grime or bird deposits. Such formations may attenuate radar signals. In order

to clean the radome, see directions below (Section 7.3).

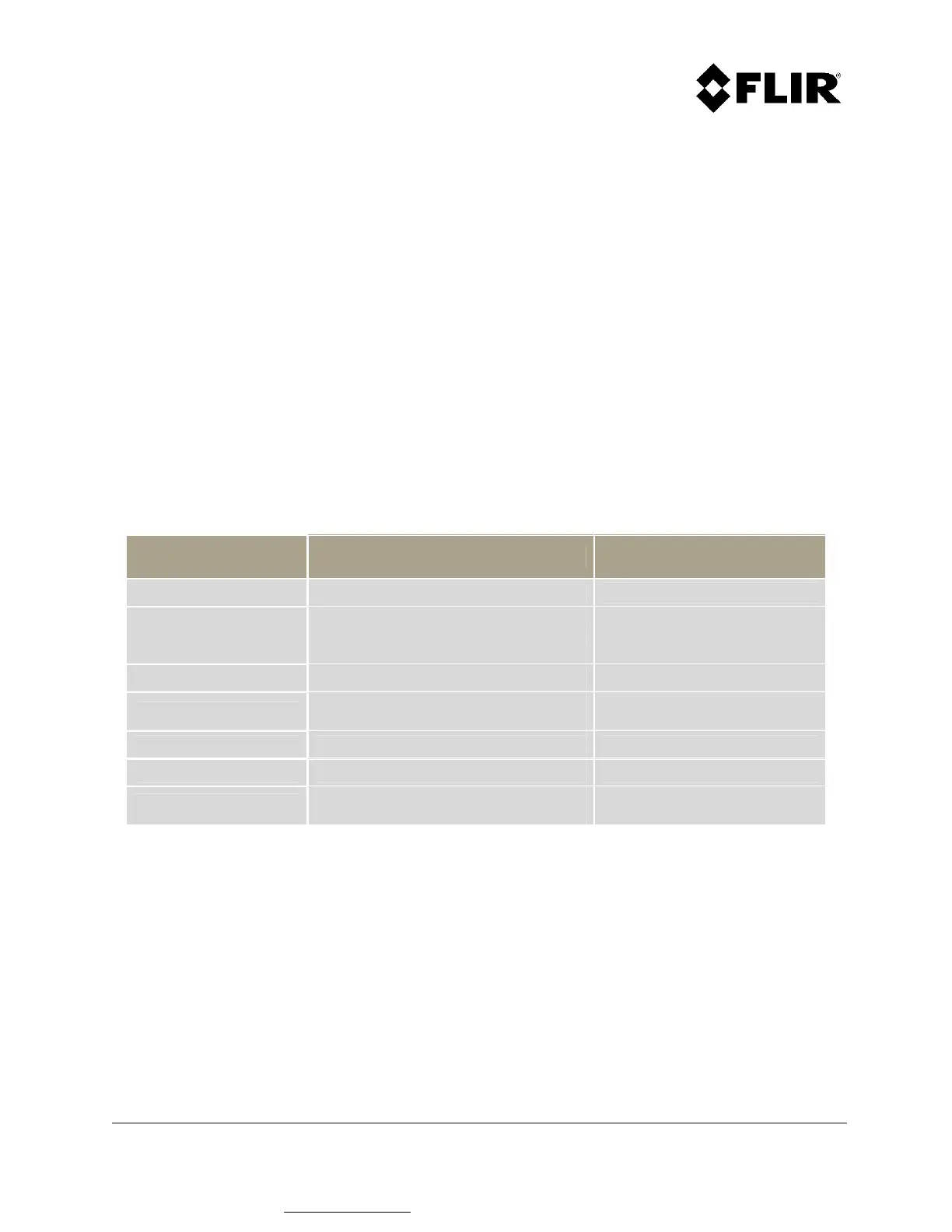

7.2 RECOMMENDED MAINTENANCE SCHEDULE

Item/Action

Frequency Comments

CLEANING

Dependent on the environment

MECHANICAL INSPECTION

Every year

To be done only by a trained

technician or return to FLIR for

inspection

MOTOR

Change every 3 years

Return to FLIR for maintenance

GASKET

Otherwise change every 3 years

SLIP RINGS

Change every 2 years

Return to FLIR for maintenance

SUPER CAPS

Change every 3 years

Return to FLIR for maintenance

GORE

™

MEMBRANE VENTS

Recommended every 2 years

Table 14 – Recommended Maintenance Schedule

Loading...

Loading...