Valve Threaded Ends:

Thread standard is either ISO 228, which is a

straight metric thread (compatible with BS-2779)

or NPT threading standard, depending on the

product number ordered.

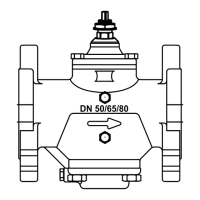

Valve Flanged Ends:

Flange ends are compatible with DIN steel flang

-

es PN10, PN16, PN25 and/or PN40 according to

EN1092-1 or ANSI steel flanges class 150 and/

or 300 according to ASME B16.5. depending on

product ordered.

Flanges are not supplied by FlowCon.

FLOWCON VALVE ACCESSORIES:

Two different types of pressure/temperature fit-

tings (p/t plugs) are available upon request for

valves with body tappings, i.e. p/t plugs with

-

out collar and p/t plugs with collar. Suitable

p/t plug choice will depend on the valve. Alterna

-

tive to p/t plugs, the valve body can be ordered

with plugs for the body tappings. Extended p/t

plugs (without collar) are standard included with

FlowCon AHU and FlowCon Wafer.

Before finger mounting p/t plugs without collar in

the body tappings (DO NOT OVER TIGHTEN),

please seal the threads of the p/t plugs. Thread

sealing is described elsewhere in this General

Instruction. P/t plugs with collar as well as plugs

are sealed by a gasket. After finger mounting,

gasket sealing requires 1-3 Nm torque.

Threaded union end connections (male or fe

-

male) for union end connected valves must have

the union nuts and the end connections should

be removed for installation.

Soldered union end connections (sweat) for

union ned connected valves must have the END

CONNECTIONS REMOVED FROM THE HOU-

SING BEFORE SOLDERING. THIS ENSURES

THAT THE O-RINGS AND INTERNAL PARTS

ARE NOT DAMAGED BY HEAT.

Capillary tubes are not to be damaged.

Therefore, do not force the tube to compress or

bend with a bending radius below 20 mm (3/4”).

Capillary tube for inserts (ACC00110)

Capillary tube is supplied with fixed M8 fitting

and O-ring at each end. Ensure that the O-ring

is greased and correctly placed before finger

mounting the capillary tube in the FlowCon

QuickDisc

®

(DO NOT OVERTIGHTEN AS THIS

WILL DAMAGE THE O-RING). If the capillary

tube is to be mounted in a FlowCon Partner Ball

or other valve with 1/4” (ISO 7/1) tapping, a 1/4”

to M8 adaptor is available (ACC00121). Thread

sealing and O-ring lubrication are described else-

where in this General Instruction.

Capillary tube for PIM-DP (F212)

Capillary tube is supplied with fixed angled

1/4” NPT fitting (F4039-14) at one end going

to the FlowCon Partner Globe with an adaptor

(ACC6584). The other tube end is to be as

-

sembled in the 1/4” NPT fitting already mounted

on the FlowCon PIM-DP. Thread sealing is de

-

scribed elsewhere in this General Instruction.

FLOWCON INSERTS:

Please see specific installation instruction for

selected insert (Green, EVS, E-JUST, Composite,

Stainless Steel, SDP, EDP, ADP or T-JUST) re-

garding valve housing match, installation and

setting.

FLOWCON ACTUATORS:

Please see specific installation instruction for se-

lected actuator (EV, FT, FN, FH, SM, BB or T)

regarding product fitting, mounting position and

wiring. For product match please read FlowCon

Actuator Matrix.

FlowCon General Instruction

1B95011 - 01/2019

Latest release of any FlowCon material is available on www.owcon.com

Page 3 of 4

Loading...

Loading...