Argus

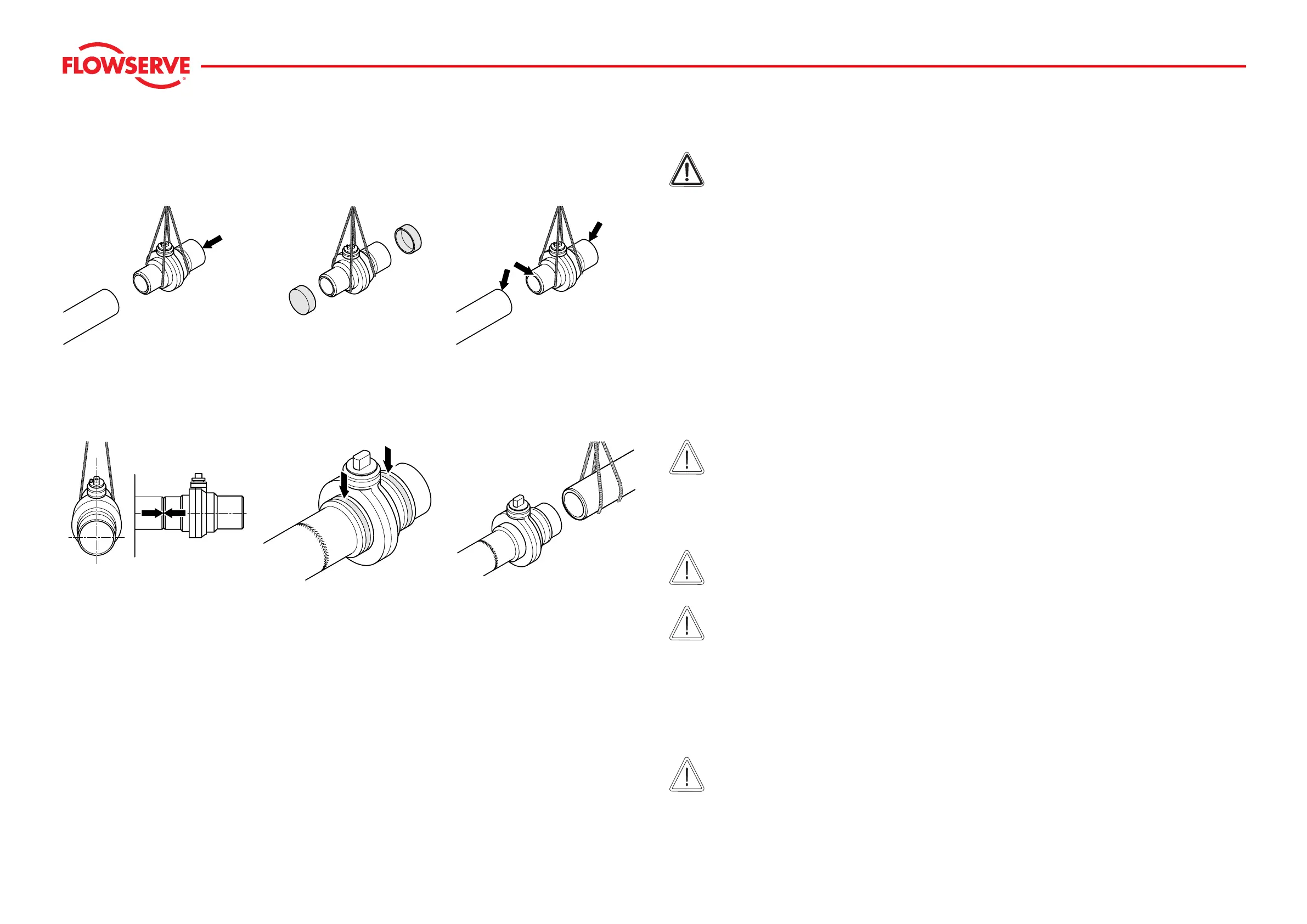

Installing the Welding Connection

8

Installing the Welding Connection

Installing the Ball Valve

0002-00-002 0002-00-004 0002-00-001

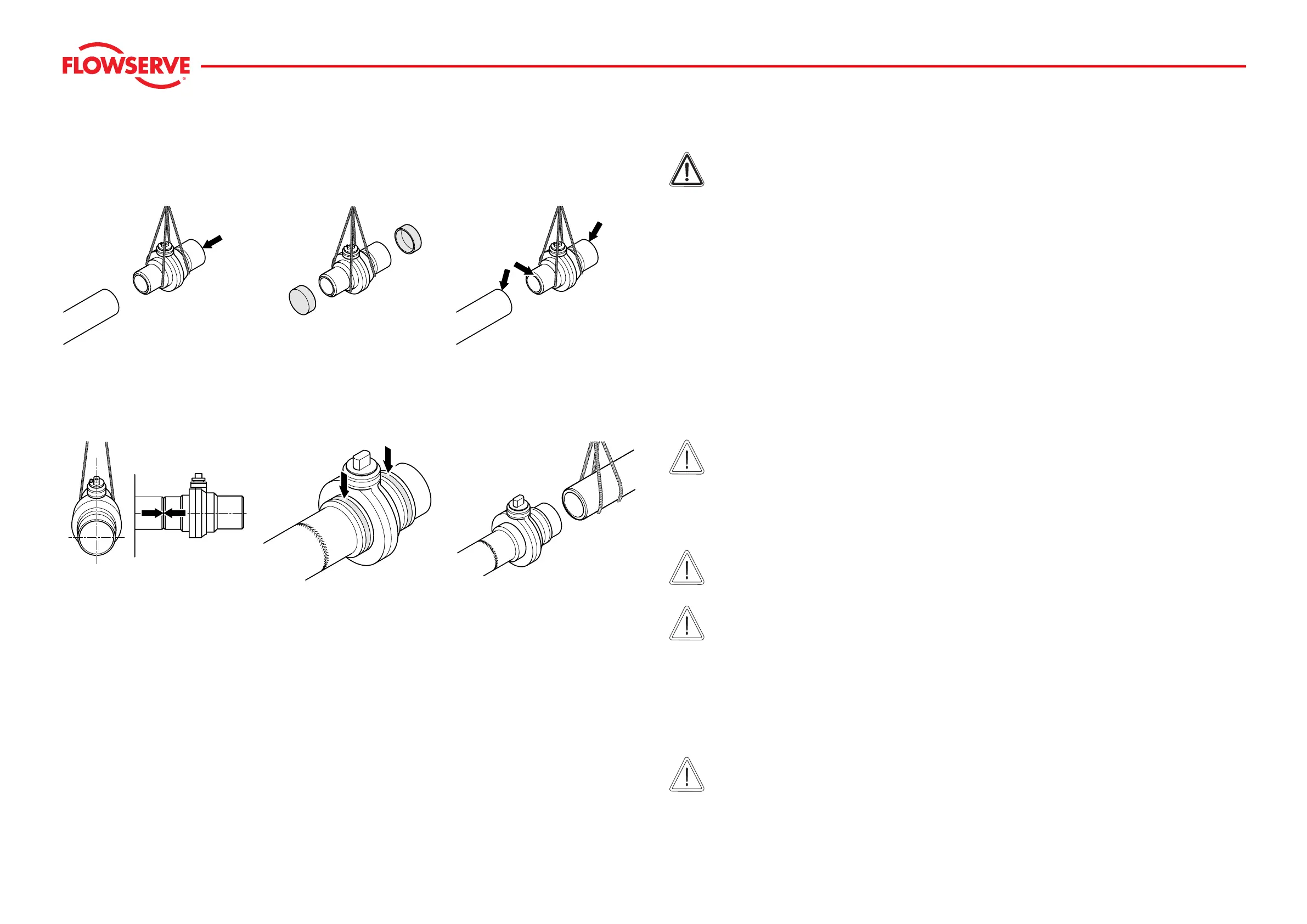

Welding the Connections

0003-00-003 0002-00-006 0003-00-005

Danger!

The local welding regulations and specifications must be complied with when carrying out welding

work.

f Transport the ball valve to the installation site using suitable hoisting gear dimensioned in accordance

with the weight and size of the ball valve (Figure 0002-00-002).

f Remo

ve the protective caps (Figure

0002-00-004).

f Clean the pipeline and connecting socket (Figur

e

0002-00-001).

f Remo

ve any paint and rust around the weld area on the pipe and welded end of the ball valve.

Ensure that a bright metal surface is obtained.

f Check that the ball valve is correctly positioned and aligned with the pipeline.

The permissible tolerances and specifications in accordance with the agreed proposed use for the ball

valve must be complied with (Figure

0003-00-003).

Due to the short length of the welded ends, there

is a risk that the soft inserts may be destroyed during the

welding work.

Caution!

Use temperature measuring strips to check that the temperature does not rise beyond the

permissible limits (100°C). The strips must be fitted to the connection near the soft inserts

(Figure

0002-00-006).

These temperature measurement strips are designed so that, when a typ

e-dependent temperature is

reached, the colour irreversibly changes from white to black.

Caution!

The temperature measurement strip must be monitored constantly throughout the welding work.

Caution!

If any change of colour is noticed, the welding work must be interrupted immediately and the weld

allowed cooling.

The temperature measurement strips can be stored at temperatures up to + 35 °C for an unlimited period of

time and are resistant to oils, greases, water and steam.

f Connect the second socket in the same way as the first one, as described before

(Figure 0003-00-005).

f After installa

tion, check for any leaks.

Caution!

Before start-up of the ball valve, the pipeline must be rinsed.

Loading...

Loading...