2

Description

This P-200 seal is a dual, cartridge mounted, end face mechanical seal,

designed for ease of installation. No seal setting dimensions are

required. Removable setting devices provide proper alignment. Installa-

tion according to the following steps will ensure a long trouble-free life

of the P-200 seal.

1 Equipment Check

1.1 Follow plant safety regulations prior to equipment disassembly:

• Lock out motor and valves.

• Wear designated personal safety equipment.

• Relieve any pressure in the system.

•ConsultplantMSDSlesforhazardousmaterialregulations.

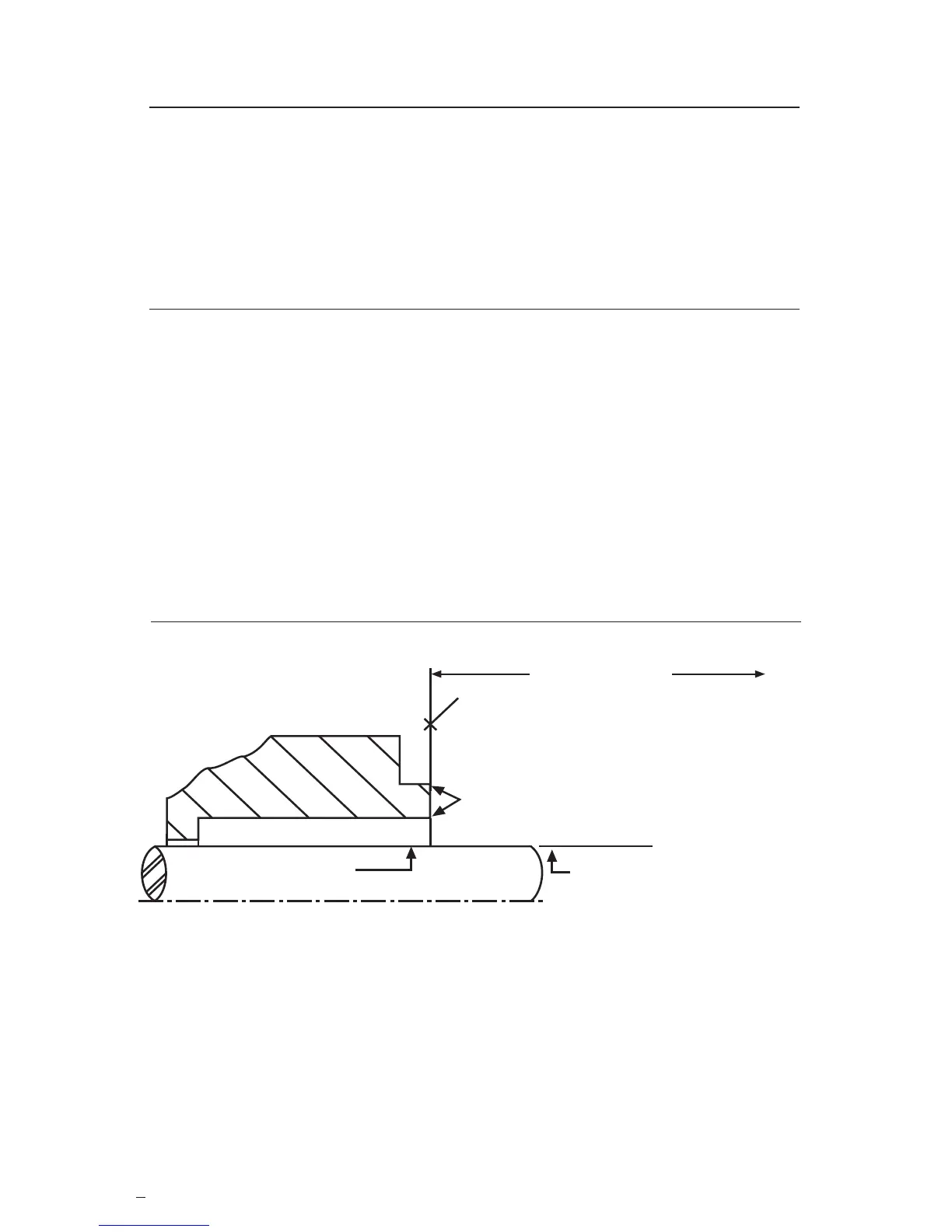

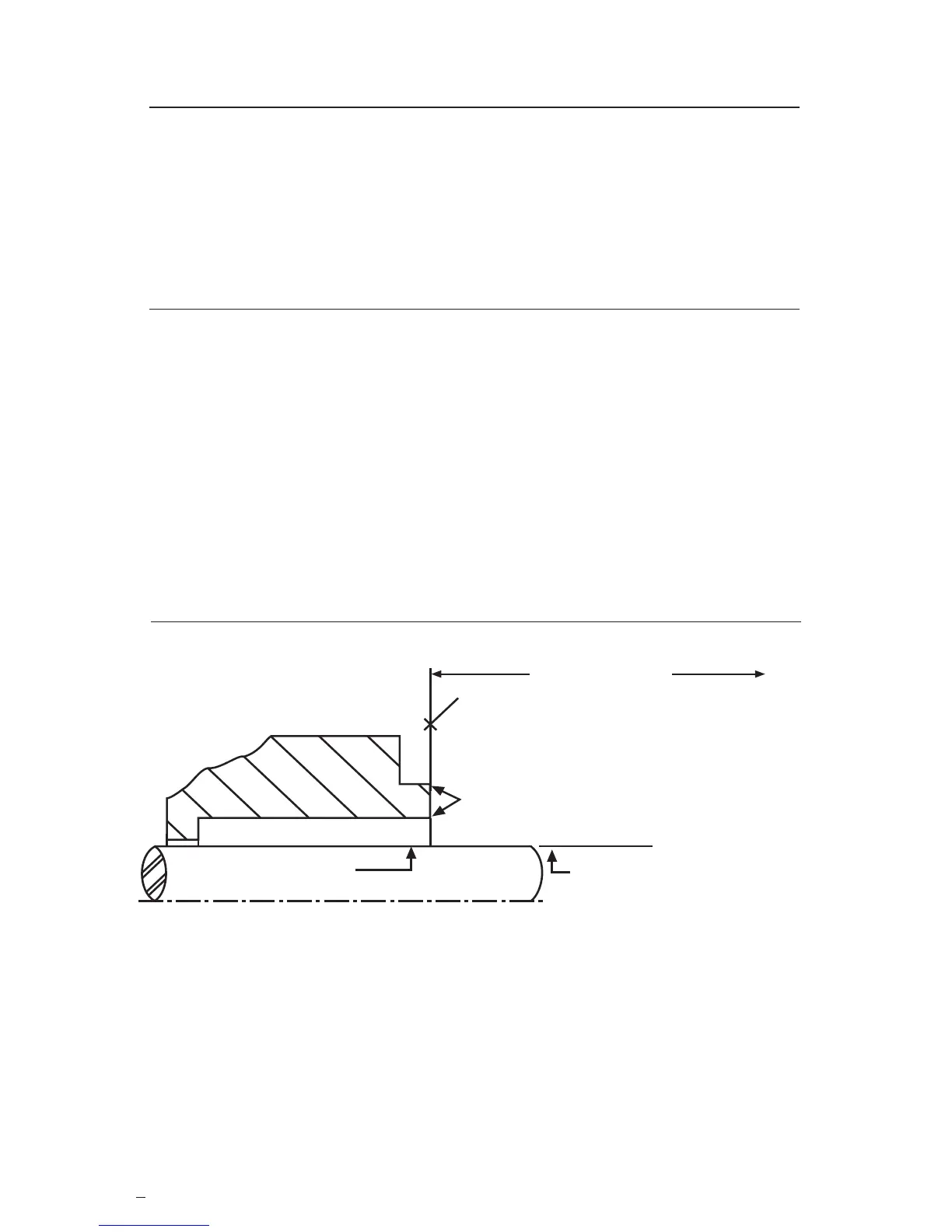

Seal Chamber Requirements Figure 1

To first obstruction

Shaft or sleeve OD

+0.000 mm (+0.000 inch)

-0.050 mm (-0.002 inch)

+0.000 mm (+0.000 inch) API 610/682

-0.025 mm (-0.001 inch) DIN/ISO

ASME

Seal housing face to have surface finish

of 1.6 μm (63 μinch) R

a

finish or better.

Gland pilot can be at either

of these register locations.

Seal housing bore to have 3.2 μm

(125 μinch) R

a

finish or better.

Sleeve or shaft finish to be

0.8 μm (32 μinch) R

a

or better.

The images of parts shown in these instructions may differ visually from the actual

parts due to manufacturing processes that do not affect the part function or quality.

Loading...

Loading...