TB0090 and TB0091 barriers have been independently tested by an

automotive paint laboratory, and proven to be non-crater-forming in both

solvent and water-based paint processes.

• Angled heatsink (TB0090) holds

logger securely in open barrier,

even if vertical, and allows strain-

free routing of cables out of the

barrier.

• Safe operation for 3 hrs at

200°C/392°F (TB0090) gives

assurance during multiple runs and process delays.

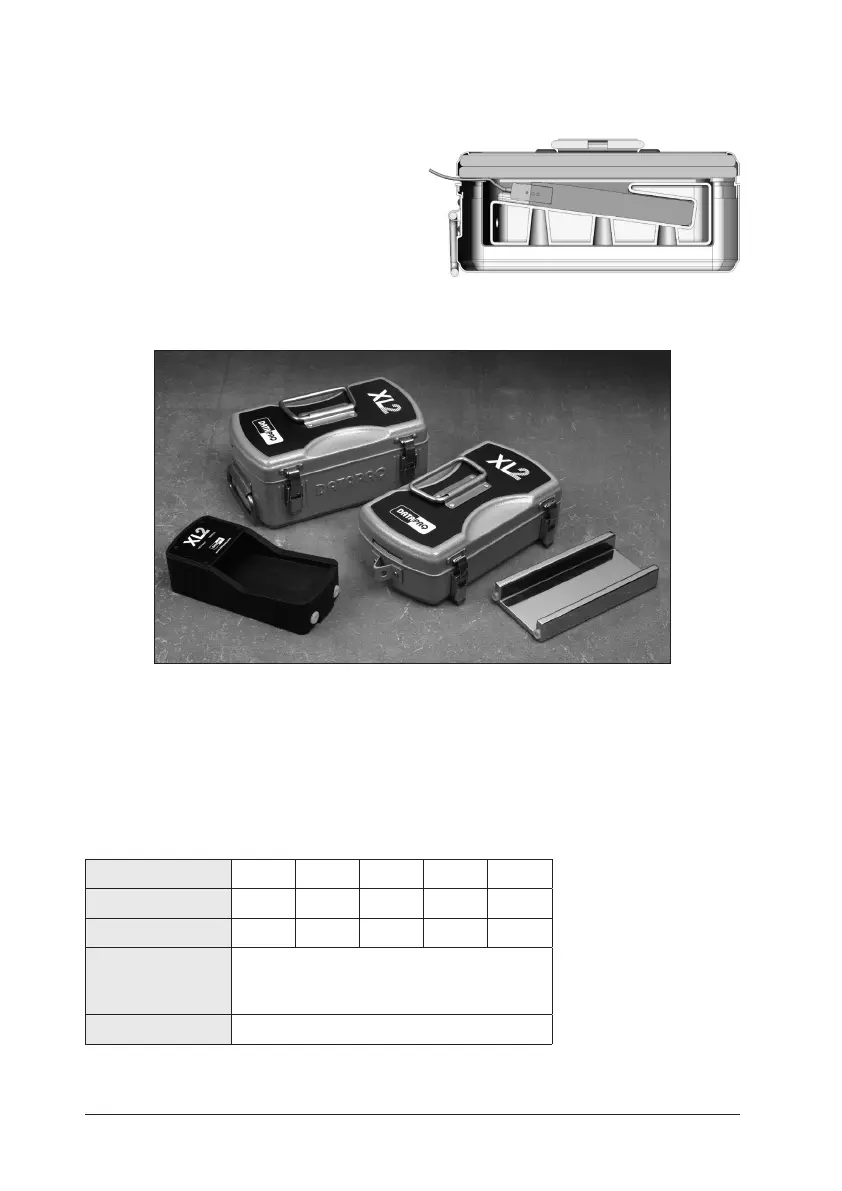

XL2 aluminum thermal barriers and their heatsinks: TB0090 (left) and TB0091

(right).

TB0090 Standard XL2 (with Heatsink)

Typical applications: automotive assembly and components, general paint/

powder/E-coat processes.

Temp °C 100 150 200 250 300

Temp °F 212 302 392 482 572

Duration (hours) 11 5.0 3.0 1.8 1.0

Dimensions Height

Width

Length

Weight

134 mm

187 mm

296 mm

3.65

kg

5.3 in.

7.4 in.

11.7 in.

8.0 lb

Heatsink 1 × TB9950A

30 Thermal Barriers and Heatsinks OVEN TRACKER XL2

Loading...

Loading...