OVEN TRACKER XL2 Thermal Barriers and Heatsinks 33

TB5010-XL IP65 Waterproof XL2 (with Heatsink)

Typical applications: dry-off ovens, processes with water-shower rinse. This

barrier is not silicone-free.

Temp °C 100 150 200 250 300

Temp °F 212 302 392 482 572

Duration (mins) 270 150 105 75 48

Dimensions Height

Width

Length

Weight

100 mm

219

mm

3

93 mm

6.0

kg

3.9 in.

8.6 in.

15.5 in.

1

3.2 lb

Heatsink 1 × TB9963

A wide range of thermal barriers is available from Datapaq for use with loggers

other than the XL2.

Selecting a Thermal Barrier

The protection which the thermal barrier needs to provide for the logger

depends on the nature of the process whose temperature is being profiled –

primarily its temperature and duration. Selection of the appropriate barrier

needs thus to be done carefully, as follows.

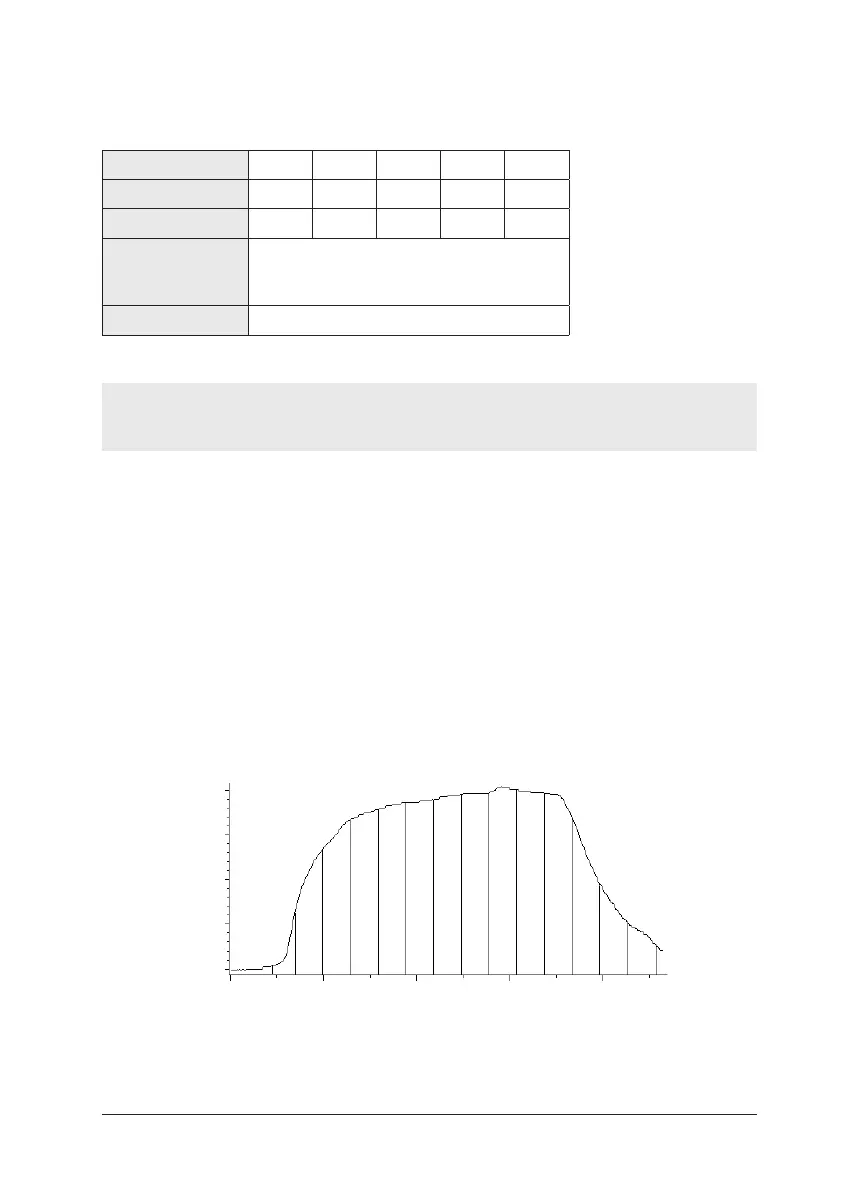

1. Plot a graph of the temperature versus time characteristics of the process.

2. Divide the horizontal axis into equal increments and draw verticals. Read

the temperature at each vertical. (The number of verticals is determined by

the complexity of the profile’s shape: more are required when the shape is

complex, fewer when it is simple.)

0:00:00

125

100

°C

75

50

25

0:10:00 0:20:00 0:30:00 0:40:00

A typical temperature profile experienced by an automotive component during curing.

The average temperature is 90°C/194°F.

Loading...

Loading...