32 Thermal Barriers and Heatsinks OVEN TRACKER XL2

TB0081 Long-duration XL2 (with Heatsink)

Typical applications: aluminum age-hardening, long low-temperature cure,

automotive single-pass; possible to send the system through the complete paint

process in an uninterrupted run – electrocoat (E-coat), primer, base and clear

coat.

Temp °C 100 150 200 250 300

Temp °F 212 302 392 482 572

Duration (hours) 24 13 9 6 –

Dimensions Height

Width

Length

Weight

182 mm

236

mm

370

mm

10.5

kg

7.2 in.

9.3 in.

14.6 in.

23.1

lb

Heatsink 1 × TB9963 + 1 × TB1001

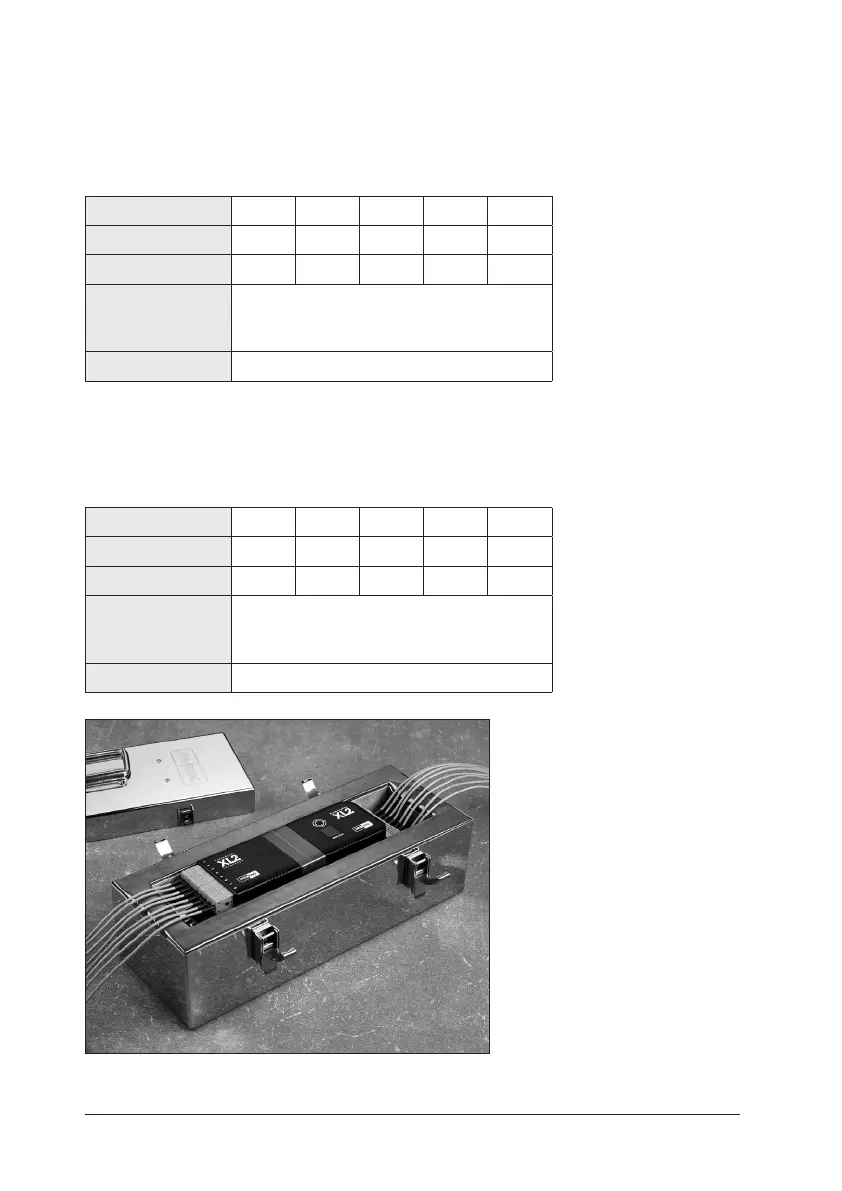

TB0083 For Dual Interface Block XL2 (with Heatsink)

This barrier is constructed of silicone-free materials (see p. 29).

Typical application: automotive assembly.

Temp °C 100 150 200 250 300

Temp °F 212 302 392 482 572

Duration (hours) 11 5 3 1.8 –

Dimensions Height

Width

Length

Weight

144 mm

172 mm

390

mm

5.95

kg

5.7 in.

6.8

in.

15.4 in.

13.1

lb

Heatsink 1 × TB9960

TB0083, a stainless-steel

thermal barrier for the XL2 in

16-channel configuration –

shown with heatsink and

logger in place.

Loading...

Loading...