18

Watch out for the propeller and for the

starting jerk, which can be powerful.

OPERATION

liquid is impaired, by unbalanced propellers or by air

sucked down by the propeller.

Vibration can also occur due to interference between

several mixers.

For another operating direction for the mixer, contact

ITT Flygt.

In continuous operation, air must not be drawn down

by the propeller (a vortex must not form).

NOTE! In order to avoid overheating the ma-

chine, it must always work completely sub-

merged in the liquid.

During operation of PP-pump

Test-run the pump and note the current surge during

start-up. At the instant of starting, it is normal for the

current to exceed the operating current by 10—20 %

for a few seconds. The steady-state current should be

less than the rated current.

Excessive power consumption may be caused by:

— too high head

— wrong rotation

— high viscosity or density

— clogged or badly shaped propeller

— an improperly adjusted pump

— incorrect blade angle

— changing gap between propeller and inlet cone

(due to damaged cone)

Low power might be caused by:

— vortex formation

— low head

— incorrect blade angle

— changing gap between propeller and inlet cone

(due to damaged cone)

Check that the flow is non-violent and that the pump

does not vibrate.

Vibration can occur due to:

— damaged propeller

— clogged propeller

— air suction through surface - vortex

— disturbance from other pumps, uneven attacking

flow or too high head

— changing gap between propeller and inlet cone

(due to damaged cone)

Tendency to clog can easily be observed by means of

an apere.

In continuous operation, air must not be drawn down

by the propeller (a vortex must not form).

NOTE! In order to avoid overheating the ma-

chine, it must always work completely sub-

merged in the liquid.

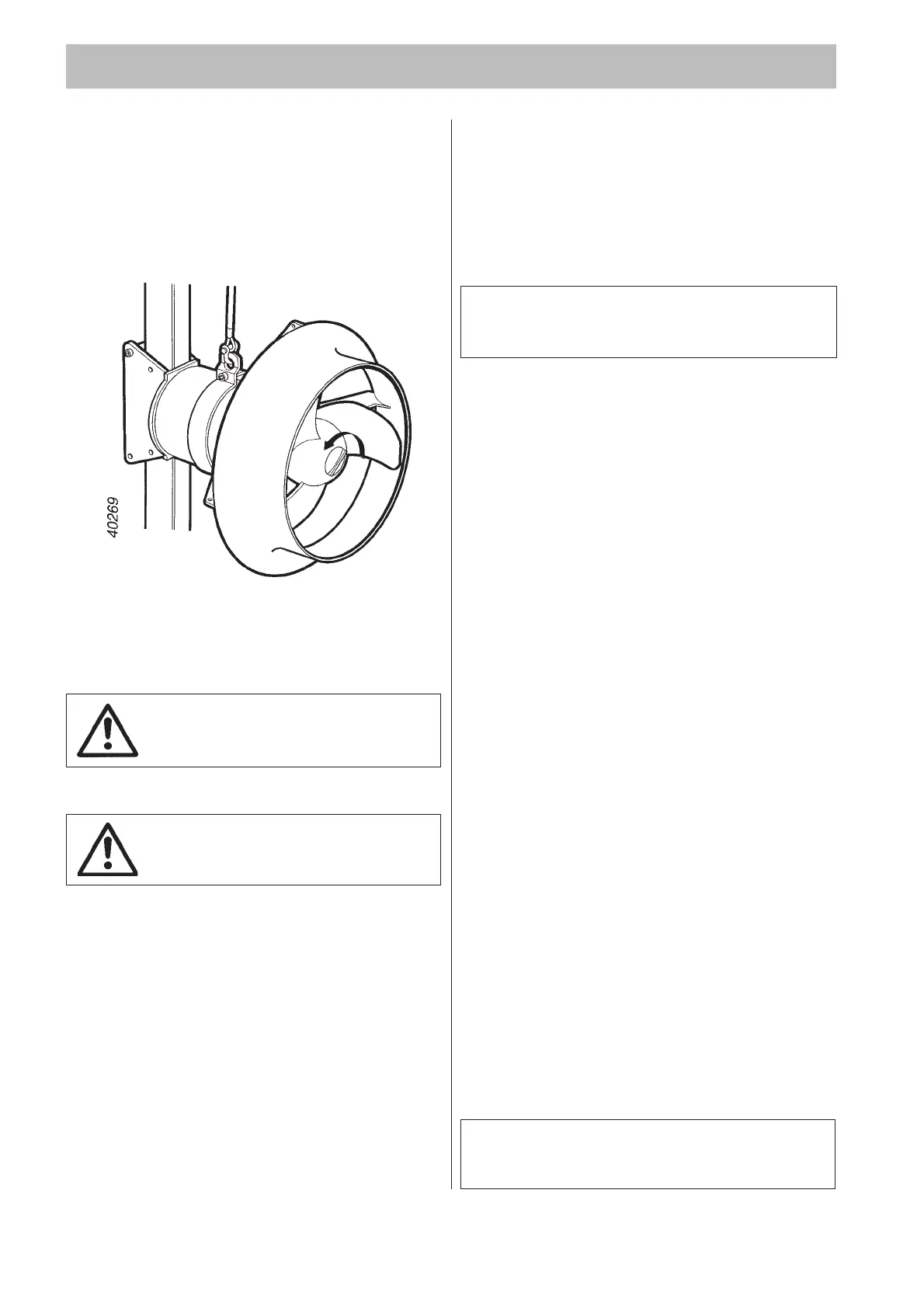

Check the direction of rotation. See the figure. The

propeller should rotate clockwise, as viewed from the

motor side.

The machine must be fixed to the guide bar during

test starting.

Before starting

Check that the oil level minimum reaches up to the

centrumline of the shaft.

Remove the fuses or open the circuit breaker and

check that the propeller can be rotated by hand.

Check that the cable entry is securely tightened.

Check that the monitoring equipment (if any) works.

During operation of mixer

Watch out for the propeller in rotation.

The mixer is intended to operate with or without jet

ring, due to its main application area. Operating with-

out jet ring means that strict carefulness must be ob-

served at test starting and in operation.

Test-run the mixer and note the current surge during

start-up. At the instant of starting, it is normal for the

current to exceed the operating current by 10—20 %

for a few seconds. The steady-state current should be

less than the rated current.

Excessive current consumption may be caused by

high viscosity or density of the liquid or an improperly

adjusted mixer.

Check accurately that the mixer does not vibrate.

Vibration can occur when mixing is too vigorous in a

small tank volume, or when the inflow or outflow of

Loading...

Loading...