26

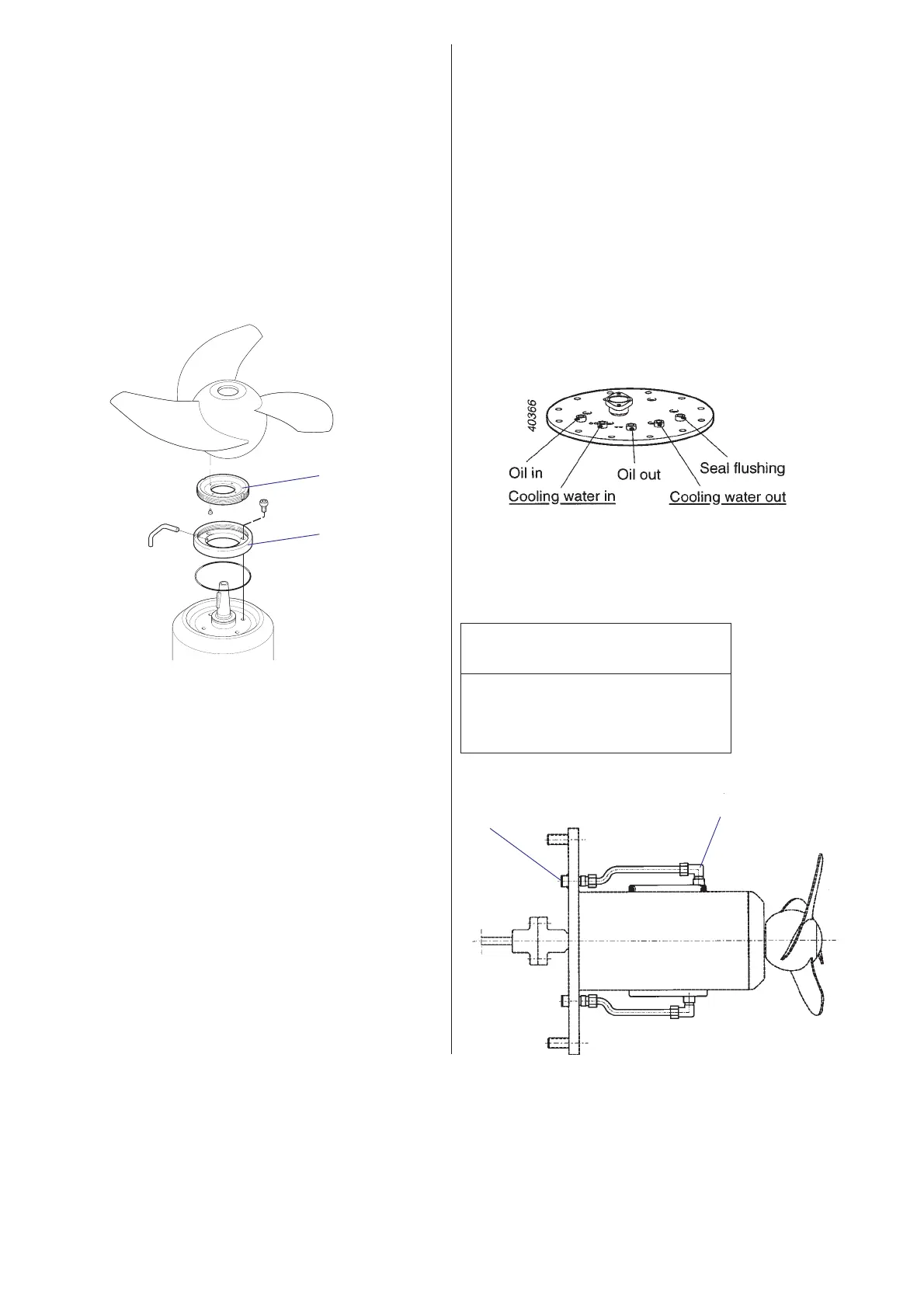

Cooling jacket

The machine can be equipped with cooling jacket.

Pipes and couplings are connected between the cool-

ing jacket and the fixing plate. Cooling water is acces-

sible at the fixing plate.

The fixing plate is provided with five threaded holes

ISO G-3/8 for inspection and change of oil, cooling

water and seal flushing.

For easy handling, the cooling water holes can be

equipped with hydraulic couplings or couplings with

hose clips.

After propeller and jet ring removal, the cooling jacket

is assembled by pushing it from the mixers’ propeller

side on the stator housing. To make it easy, soap

water can be used.

Recommended flow for the cooling water is shown in

the table below. Cooling water temperature 20°C

(68°F).

Mixer size Flow

l/min

4630, 4640 2

4650, 4660 6

4670, 4680 10

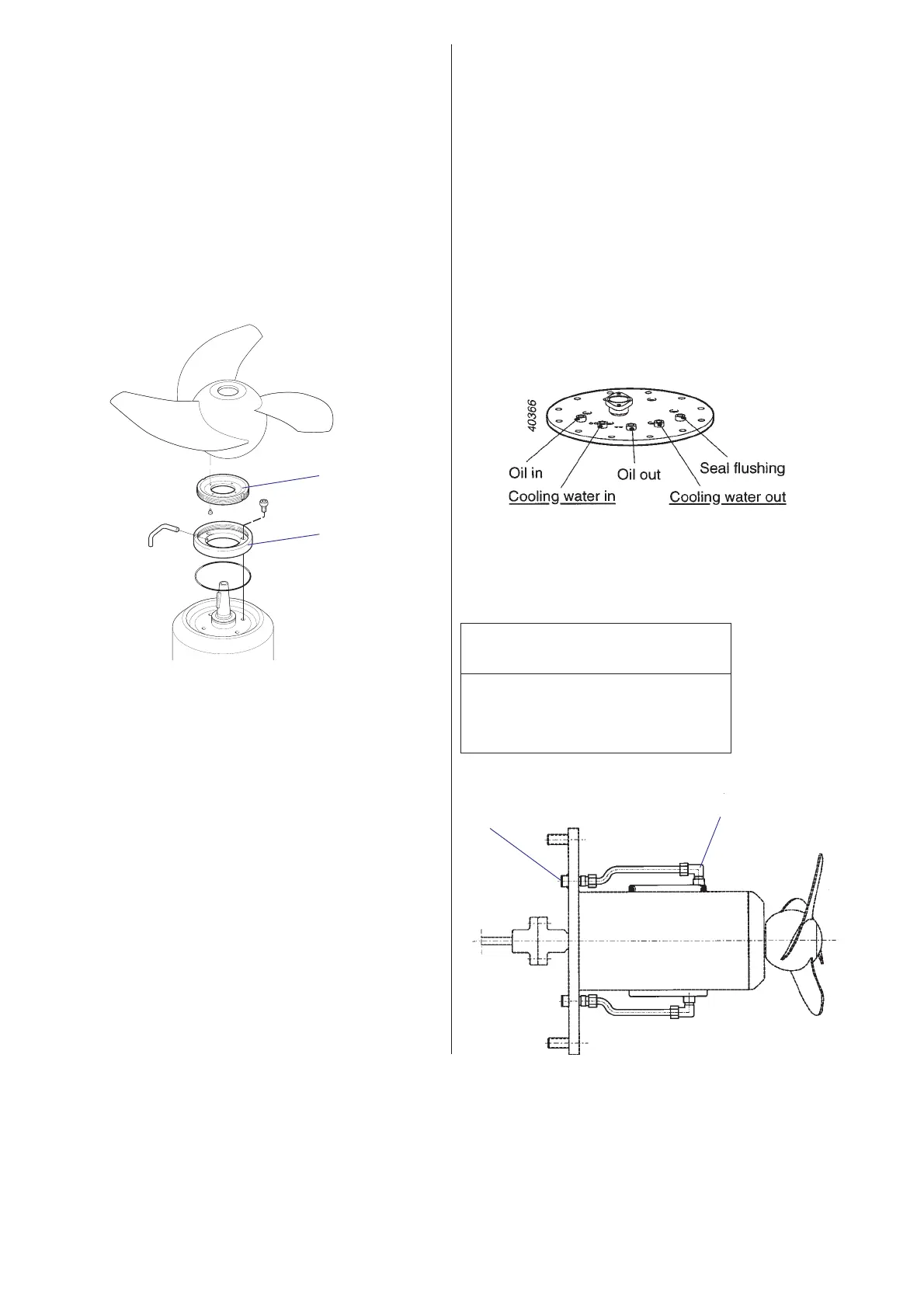

Cutting rings

Assembling of cutting rings

Center the rotatary cutting ring over the propeller hub.

Use the cutting ring as a jig and drill 4 or 8 holes Ø 4.9

mm, for the rivets.

Fix the cutting ring with the rivets.

If the machine will work with seal flushing, fit the tube

in the stationary cutting ring.

Assemble O-ring, stationary cutting ring and fix the

ring with the 4 screws.

Tightening torque 6—8 Nm.

40299

Rotary

cutting

ring

Stationary

cutting

ring

Cooling jacketCooling

water hole

Loading...

Loading...