8

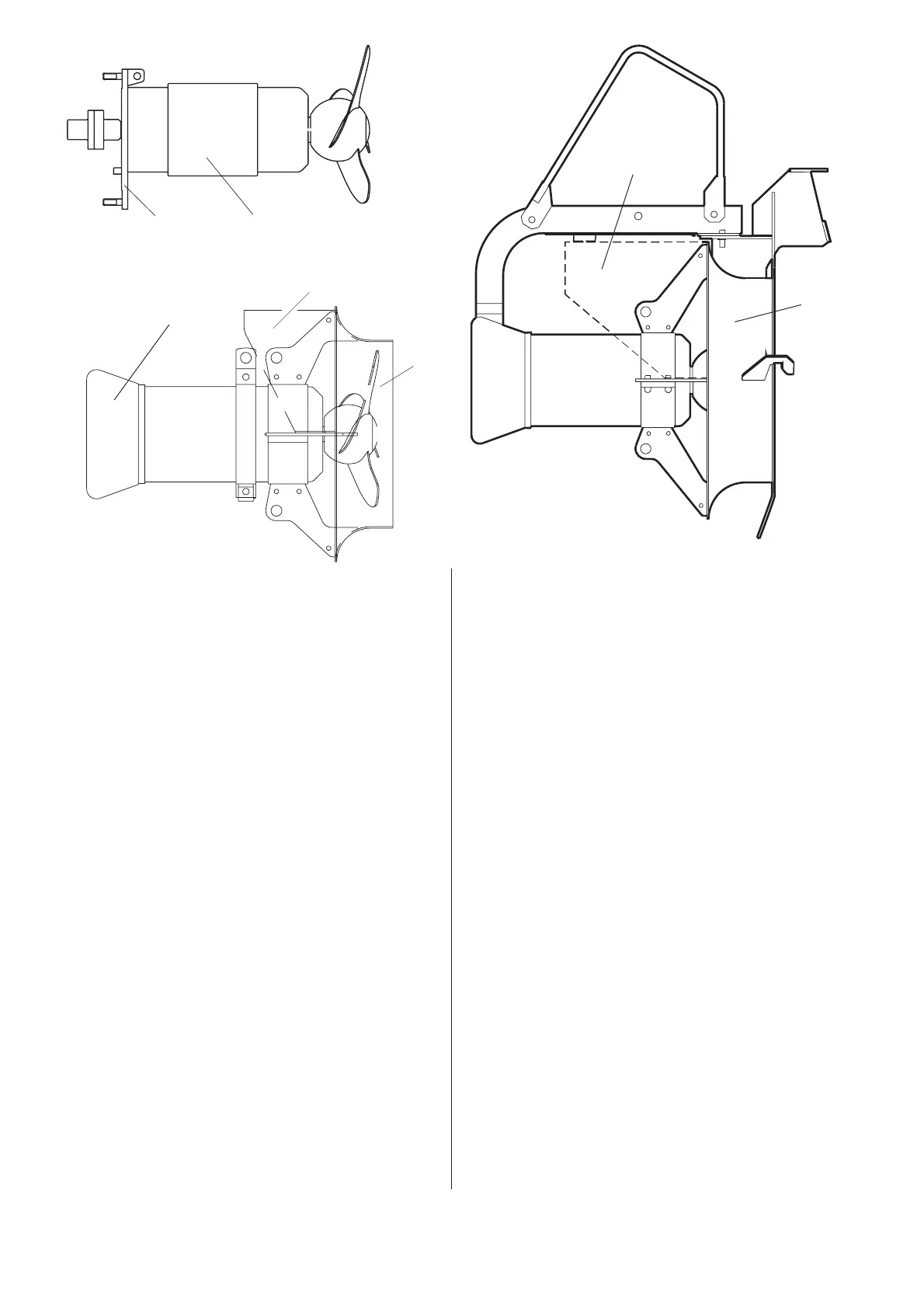

8. Propeller

The propeller is three-bladed and the blades have a

large width and a thin profile, a smooth surface and

are back-swept. This gives a highly efficient and clog-

free operation.

The propeller angle can be adjusted to meet

requirements. Angles between 4° and 19° are

possible, but restricted upwards depending on version

and applications due to available power.

9. Flush protection

The mixer and the PP-pump can be equipped with

accessories for water or air flushing systems. Flushing

the propeller hub area and the outer seal reduces the

risk of sticking when mixing reactive slurries.

10. Cutting rings

The propeller can be equipped with cutting rings to

prevent clogging of the hub area.

The cutting rings can be used with or without flushing.

These are intended to be used for mixer applications,

where liquids with long fibres are to be mixed.

11. Seal protector

The mixer and PP-pump can be equipped with seal

protector to prevent clogging.

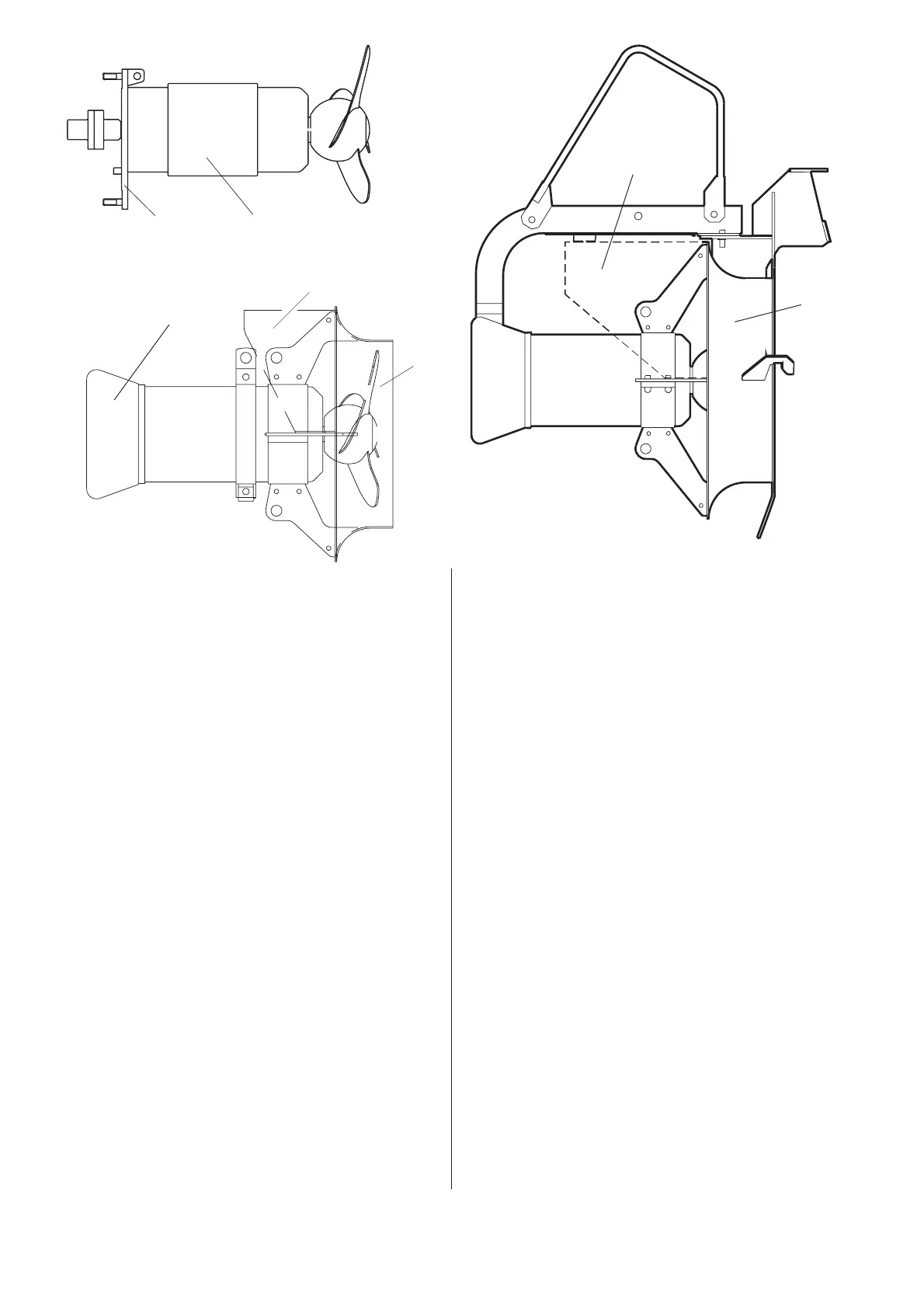

12. Fixing plate

The mixer is available with two types of fixing plate,

one for guiding bar installation and one for flange

mounted mixer.

13. Cooling jacket

Normally the stator is cooled by the surrounding liquid.

External cooling (cooling jacket) is available as option.

14. Vortex protection shield

In order to avoid vortex the machine can be equipped

with a protective shield.

15. Jet ring for mixer

The mixer can be operated with or without a jet ring.

The jet ring improves the efficiency and directs the jet.

NOTE. Operation without jet ring affects the

power consumption.

16. Inlet cone for PP-pump

The inlet cone is designed to give the best influence

on the created flow .

Discharge connection for PP-pump

The function of the discharge connection is to fix the

inlet cone onto a pipe or a diffusor.

Guiding equipment for PP-pump

The guiding equipment consists of two pipes (guide

bars) and upper guide bar holders.

Installation for PP-pump

The PP-pump should be installed horizontally on a

wall and guided vertically along the wall.

The pump slides down along guide bars and connects

automatically to the discharge connection. The flange

of the inlet cone directs the pump at guiding and

secures the correct position on the discharge con-

nection.

14

16

15

14

12

12

11

40340

12

13

Loading...

Loading...