7

12345

667

8

40811

12

9/10/11

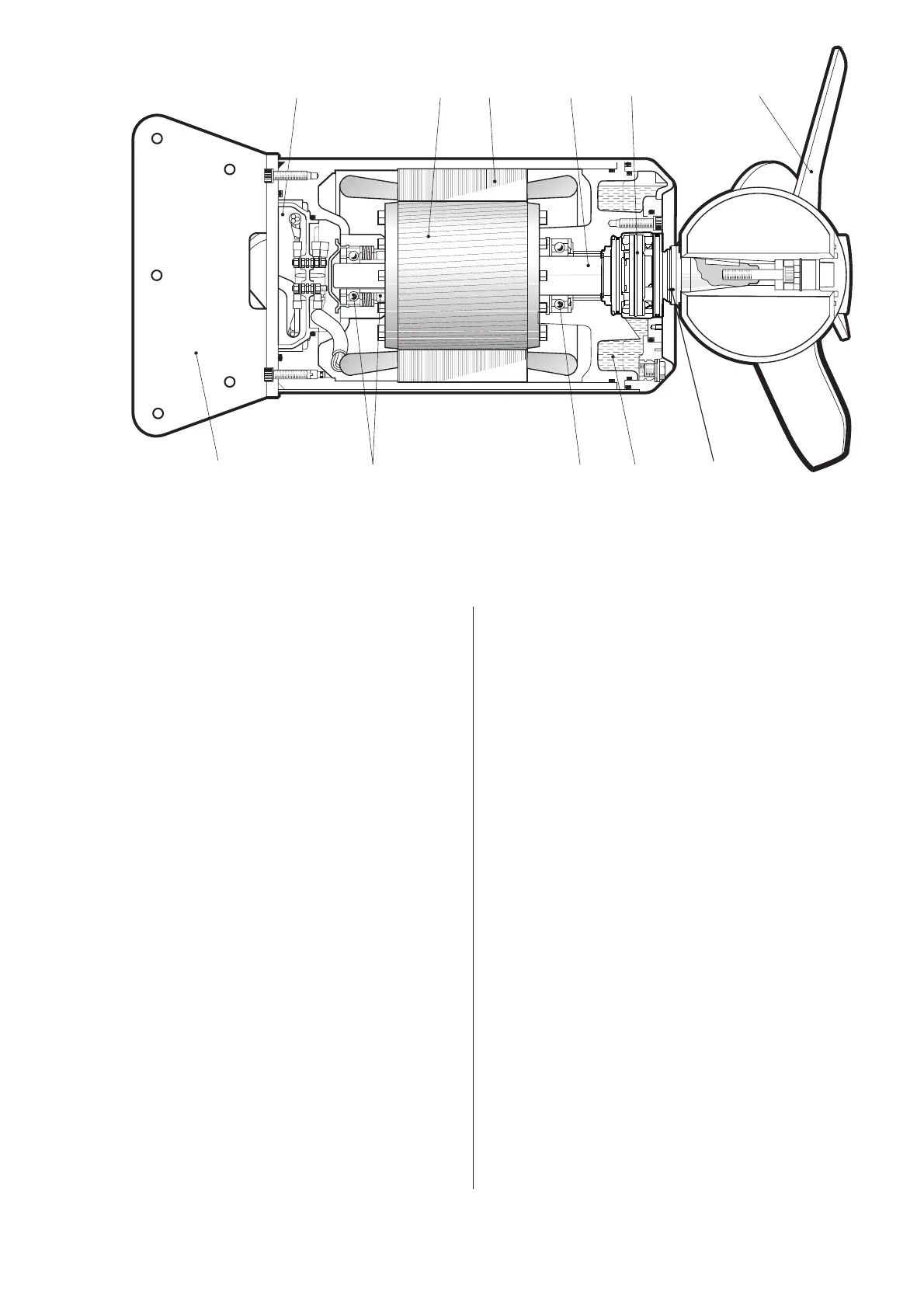

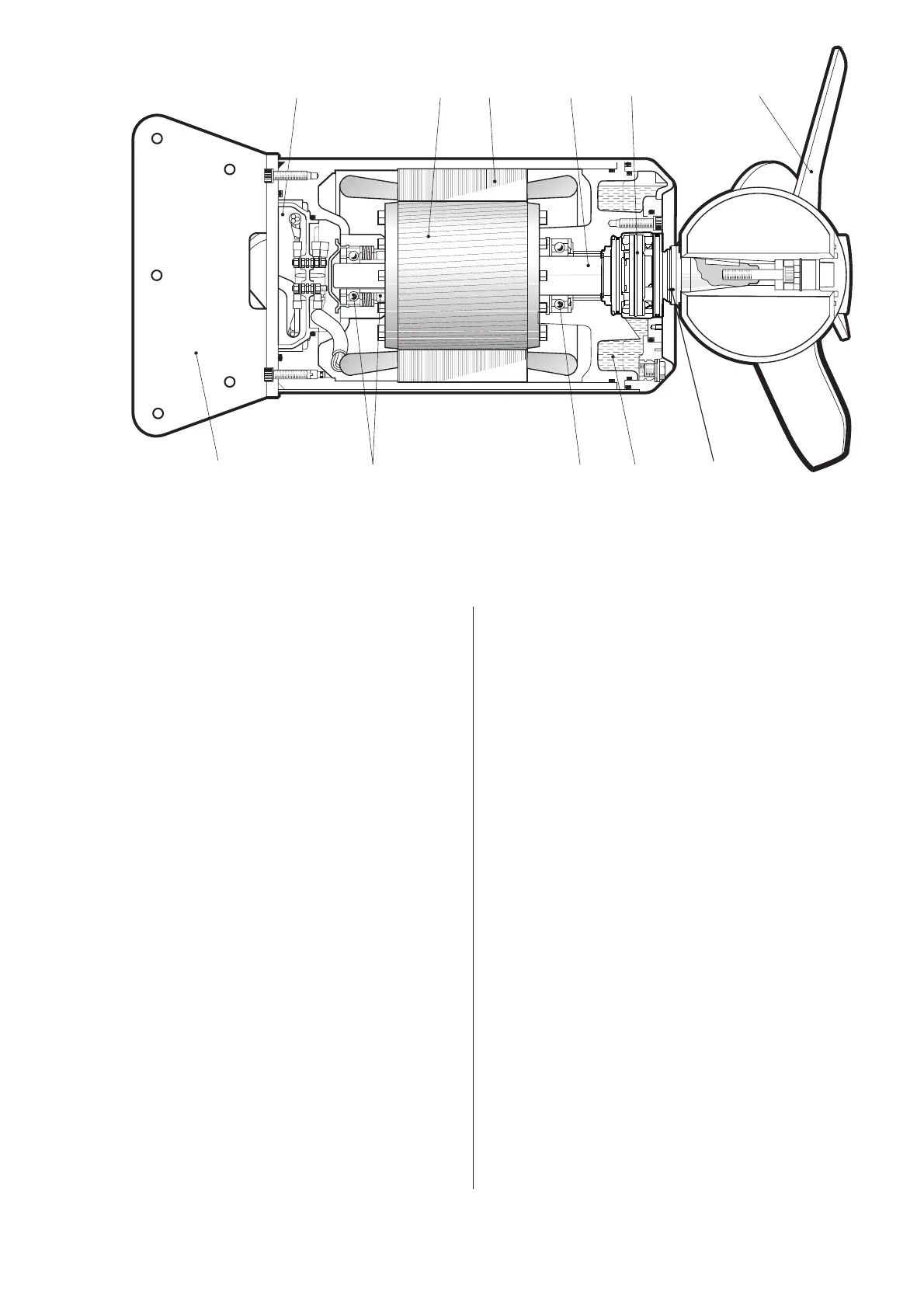

Design

See also “Electrical connections” and separate instruc-

tions for starter equipment.

The machine can be equipped with sensors, CLS for

sensing water in the oil and/or FLS for sensing water

in the stator casing. The CLS sensor is not applicate

for Ex-approved machines.

NOTE! 4630 and 4640 can only be equipped with FLS.

4. Shaft

The motor shaft is delivered with the rotor as an inte-

gral part.

The motor shaft is completely sealed and will not

come in contact with the liquid.

5. Shaft seals

Mechanical face seals plug-in type, which combines

an inner and an outer seal into one, rigid unit.

6. Bearings

The shaft is carried in one single-row angular contact

ball bearing and a single-row cylindrical roller bearing

together with a single-row angular contact ball bearing.

The bearings are dimensioned for more than 100 000

(L 10 aa) hours of operation.

7. Oil casing

The oil lubricates and cools the seals and acts as an

additional barrier against penetrating liquid.

Pressure build-up within the oil casing is reduced by

means of a built-in air volume.

Cable entry

The cable entry has two compressible rubber bush-

ings to seal off and to relieve the cable.

1. Junction box

The junction box is completely sealed off from the

surrounding liquid and the stator casing.

2. Motor

Squirrel-cage 3-phase induction motor for 50 Hz or 60

Hz.

The motor is started by means of direct on-line start.

The motor can be run continuously or intermittently

with a maximum of 15 evenly spaced starts per hour.

The stator is insulated in accordance with class H

(180°C, 355°F). The motor is designed to supply its

rated output at ± 5 % variation of the rated voltage.

Without overheating the motor, ± 10 % variation of the

rated voltage can be accepted provided that the motor

does not run continuously at full load. The motor is

designed to operate with a voltage imbalance of up to

2 % between the phases.

3. Monitoring equipment

The stator incorporates three thermal contacts con-

nected in series.

The thermal contacts open at 125°C (260°F).

NOTE! The thermal contacts should be connected for

liquid temperature up to 40°C (105°F) and always for

Ex approved machines.

Loading...

Loading...