Paragraphs 78-81

FORD

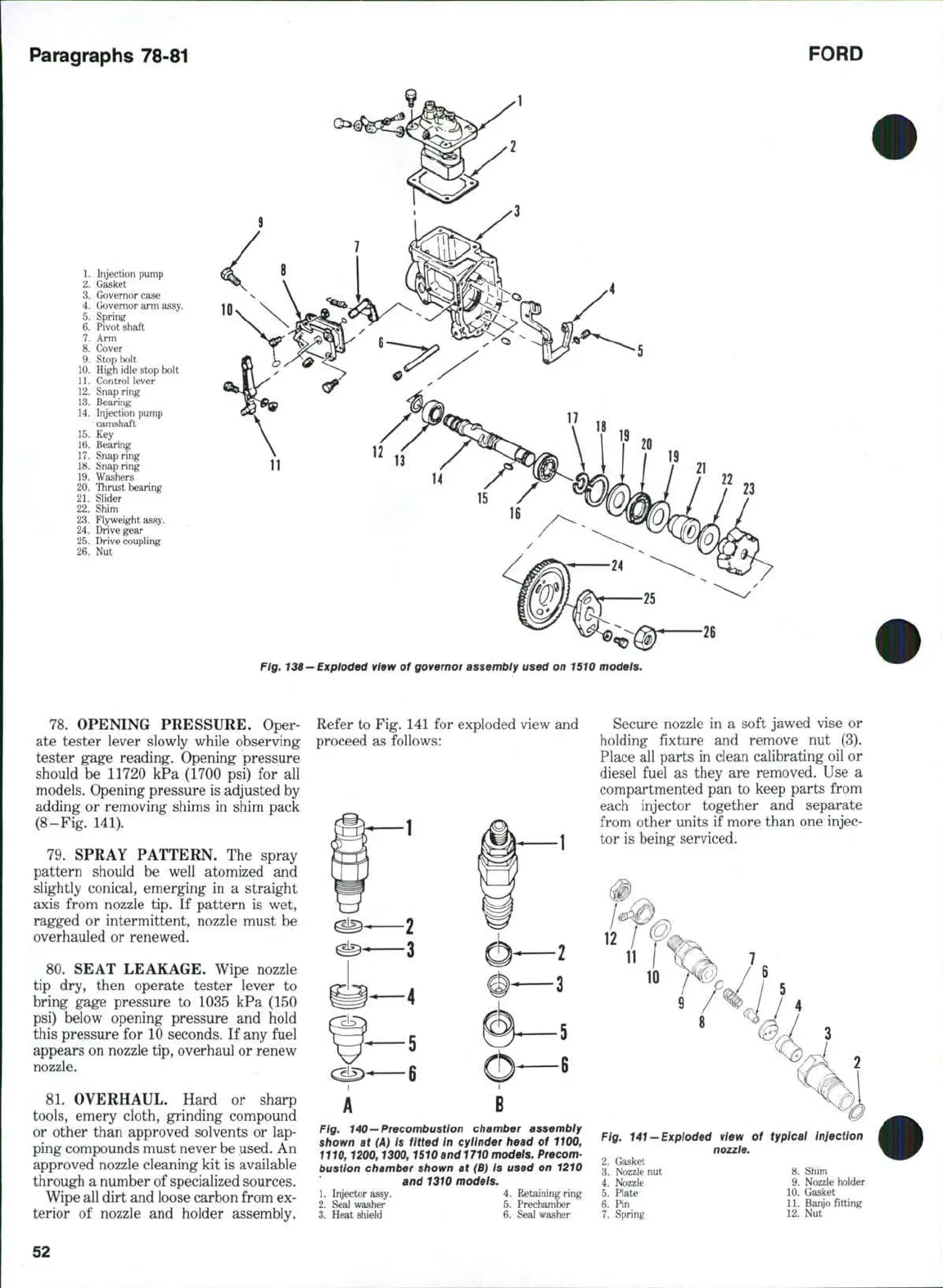

1. Injection pump

2.

Gasket

3.

Governor case

4. Governor arm assy,

5. Spring

6. Pivot shaft

7.

Arm

8. Cover

9. Stop bolt

10. High idle stop bolt

11.

Control lever

12. Snap ring

13.

Bearing

14. Injection pump

camshaft

15.

Key

16. Bearing

17.

Snap ring

18.

Snap ring

19. Washers

20. Thrust bearing

21.

Slider

22. Shim

23.

Flyweight assy.

24. Drive gear

25.

Drive coupling

26.

Nut

It

23

Fig,

138

—

Exploded

VIBW

of governor assembiy used on 1510 models.

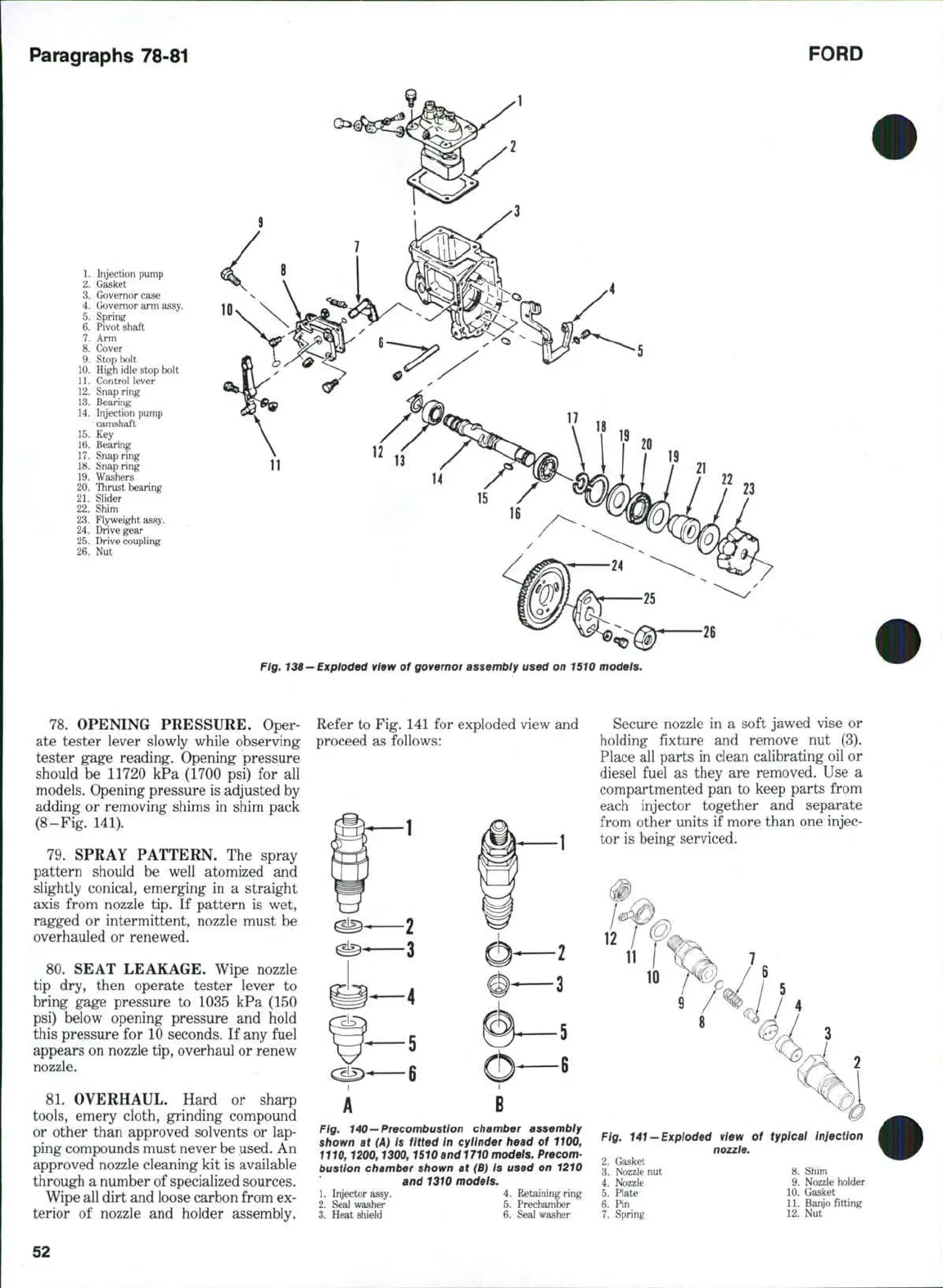

78.

OPENING PRESSURE. Oper

ate tester lever slowly while observing

tester gage reading. Opening pressure

should

be

11720

kPa

(1700 psi)

for all

models. Opening pressure is adjusted by

adding

or

removing shims

in

shim pack

(8-Fig. 141).

79.

SPRAY PATTERN.

The

spray

pattern should

be

well atomized

and

slightly conical, emerging

in a

straight

axis from nozzle tip.

If

pattern

is

wet,

ragged

or

intermittent, nozzle must

be

overhauled

or

renewed.

80.

SEAT LEAKAGE. Wipe nozzle

tip

dry,

then operate tester lever

to

bring gage pressure

to

1035

kPa

(150

psi) below opening pressure

and

hold

this pressure

for

10 seconds.

If

any fuel

appears on nozzle tip, overhaul or renew

nozzle.

81.

OVERHAUL. Hard

or

sharp

tools,

emery cloth, grinding compound

or other than approved solvents

or

lap-

ping compounds must never be used. An

approved nozzle cleaning kit is available

through a number of specialized sources.

Wipe all dirt and loose carbon from ex-

terior

of

nozzle

and

holder assembly.

Refer to Fig. 141 for exploded view and

proceed

as

follows:

Fig, 140—Precombustion chamber assembiy

shown at (A) is fitted in cylinder head of 1100,

1110,1200,1300,1510 and

1710

models, Precom-

bustion chamber shown at

(B)

is used on 1210

and 1310 modeis.

1. Injector assy.

4.

Retaining ring

2.

S^

washer

5.

Prechamber

3.

Heat shield

6.

Seal washer

Secure nozzle

in a

soft jawed vise

or

holding fixture

and

remove

nut (3).

Place all parts in clean calibrating oil

or

diesel fuel

as

they

are

removed. Use

a

compartmented pan

to

keep parts from

each injector together

and

separate

from other units

if

more than one injec-

tor is being serviced.

Fig, 141-Exploded view of typical iniectlon

nozzle,

2. Gasket

3.

Nozzle

nut 8.

Shim

4. Nozzle

9,

Nozzle holder

5. Plate

10.

Gasket

6.

Pin 11.

Banjo fitting

7. Spring

12. Nut

52

Loading...

Loading...