This document is an Operator Handbook for the Ford DSG-423 engine, manufactured and distributed by Engine Distributors, Inc. (EDI). The handbook, identified by EDI 1060020 and IMT #99905334, was published in July 2007. It covers engines designed to operate on Liquefied Petroleum Gas (LPG), Gasoline (EFI), and Natural Gas (NG). Notably, the document states that the DSG-423 engine is "Used through REFUSE3G3121003. Replaced with MSG425 engine," indicating it may be an older model or one being phased out.

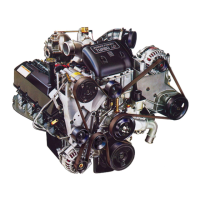

Function Description

The Ford DSG-423 engine is a 4-stroke spark ignition engine designed for off-road industrial applications. It is capable of running on multiple fuel types: LPG, Gasoline (Electronic Fuel Injection - EFI), and Natural Gas (NG). The engine's primary function is to provide power for various equipment, with its operation and maintenance being critical for ensuring its longevity and performance. The handbook emphasizes the importance of correct operation and regular maintenance to achieve the high performance built into the engine unit and minimize operating costs.

Important Technical Specifications

General Specifications:

- Engine Type: I-4 cylinder 4 stroke spark ignition.

- Liter/CID: 2.3/140

- Bore: 87.5 mm (3.44 in.)

- Stroke: 94 mm (3.70 in.)

- Number of cylinders: 4

- Compression Ratio: 9.7:1

Fuel System:

- LPG Type: Liquefied Petroleum Gas, Fumigation.

- LPG Fuel Specification: EN589 (European) HD5 (USA).

- NG Type: Natural Gas, Fumigation.

- NG Fuel Specification: 38.7 MJ/m³ (UK) 39.0 MJ/m³ (USA).

- Gasoline Type: Unleaded 87 or 89 Octane (Gasoline blends not to exceed 10% Ethanol by volume Octane Index of 87 or 89).

- Fuel Pump Pressure Normal: 75 psi.

Lubrication System:

- Max. Oil Pressure: Hot@2000 rpm: 200-268 kPa (29-39 psi).

- Oil Type: Super Premium SAE5W20 WSS M2C930-A.

- Service Oil fill capacity (including filter): 4.0 qt. (3.78 L) = 3.5 qt. Pan + 0.5 qt. filter.

- Oil filter: Ford Service Part Number: 1S7G 6714 DA, Motorcraft: FL 910.

Cooling System:

- Thermostat Type: Wax element.

- Thermostat Commences opening: 88.9°C.

- Thermostat Fully open: 100°C.

- Coolant: 50% Motorcraft Premium Gold engine coolant plus 50% clear water, Ford Specification: WSS-M97B51-A1.

Drive Belts:

- Front end accessory drive belt & tension: Serpentine belt with automatic tension control.

Electrical System:

- Polarity: Negative to earth (ground).

- Battery Capacity: 750 CCA / 140 RC.

- Generator Drive Belt Tension (8K Poly Belt): Tension is within specification if the tensioner is within the indicator markings.

- Generator Output: 95 Amp.

Ignition System:

- Spark Plug Type: AGSF32YPC.

- Spark Plug Gap: 1.25 - 1.35 mm (0.049 - 0.053 in.).

- Firing Order: 1-3-4-2.

Tightening Torques:

- Oil Pan Drain Plug: 28 Nm (21 FT. LB.).

- Spark Plugs: 15 Nm (11 FT. LB.).

- Oil Filter: 25-151.6 LB. IN.

Usage Features

The engine is equipped with various controls and instruments for operation:

- Ignition or Isolation Switch: A four-position switch (Auxiliary Circuits, Off, Run, Start) controls electrical equipment and engine starting. The "Off" position allows key removal, preventing unauthorized operation.

- Safety Switch (where fitted): A low oil pressure/high water temperature safety switch automatically shuts off the ignition under unsafe conditions. An override button on the instrument panel is used for starting.

- Power Take-off (where fitted): A control handle engages/disengages the power take-off clutch. Smooth engagement is crucial to prevent slippage and damage.

- Throttle Control (where fitted): Adjusts engine speed. Initial adjustment is made by pressing a release button and pulling/pushing the knob, with fine adjustment by turning the knob. For EFI Governor applications, the ECM automatically adjusts speed for cold start and altitude.

- Fuel Select Switch (where fitted): For dual-fuel engines, this switch allows selection of the fuel being used.

- Instruments: A typical instrument panel includes an Ammeter (or Battery Condition Indicator), Tachometer, Hourmeter, Oil Pressure Gauge, Temperature Gauge, Malfunction Indicator Light (MIL), Charge Indicator Light, and the Safety Switch Override Button. The MIL illuminates for engine malfunctions like low oil pressure or high engine temperature.

Starting the Engine:

- Before starting, ensure the engine is free from transit damage, radiator is full, oil level is correct, and battery is charged.

- For cold starts, disconnect driven equipment (if possible) and turn the ignition to ON to check warning lights. Operate the starter until the engine fires, depressing the safety switch override button if fitted. Set a fast idle until normal operating temperature is reached.

- A CAUTION warns against prolonged cranking (over 30 seconds) and recommends waiting 3-4 seconds between attempts to prevent starter/engine damage.

Stopping the Engine:

- Under normal conditions, lower engine speed to idle, disengage the clutch, and turn the ignition to OFF. If the engine has been running under high power, allow it to idle for a few minutes to cool down.

- Under abnormal overheating, if the engine continues to run after turning off the ignition, turn the ignition back ON and allow it to idle until it cools and stops.

- A WARNING is provided for checking a hot engine's radiator cap, emphasizing slow, counter-clockwise turns to release pressure before full removal to prevent injury.

Running-In Procedure:

- New or reconditioned engines should not run at high speeds or full load for the first 25 hours. Load and speed can gradually increase. After 50 hours, perform listed maintenance operations.

Maintenance Features

The handbook provides detailed instructions for lubrication and maintenance, emphasizing their importance for engine service life. EDI Distributors are available for repairs and regular maintenance.

Recommended Maintenance Schedules:

A comprehensive schedule is provided, detailing daily, after 1st 50 hours, every 100 hours, every 200 hours, every 400 hours, every 800 hours, and every 4 years max. operations. Key operations include:

- Daily: Check engine oil and coolant levels, inspect for leaks, check instruments and starting functions, inspect hoses/pipes and electrical wiring.

- Every 100 hours: Change engine oil and renew oil filter, lubricate PTO bearings.

- Every 200 hours: Check and adjust drive belt tension.

- Every 400 hours: Check/renew gasoline fuel filter, check/renew dry fuel filter, renew air cleaner element, clean/adjust/test/replace spark plugs, check nuts & bolts for tightness.

- Every 800 hours: Adjust PTO clutch release & shaft bearings, renew PCV valve, clean PCV hoses/tubes/fittings.

- Every 4 years max.: Clean coolant filler cap, renew cap if seal has deteriorated.

Recommended Lubricants:

- CAUTION against using supplemental oil additives.

- Emphasizes oil cleanliness and proper storage.

- Recommends Ford/Motorcraft "Formula E" SAE 5W-20 engine oil or equivalent meeting Ford Specification WSS-M2C930-A (API Classification – SJ). SH oils are acceptable if SJ is unavailable.

- For LPG or Natural Gas applications, oils labeled SH and/or SJ are required. Diesel engine oils (CC or CD) are not acceptable.

Change Engine Oil:

- Warm engine, ensure equipment is level and stopped.

- Drain oil into a large pan, remove oil filler cap and drain plug.

- Replace drain plug, refill with correct oil quantity, replace cap, run engine for 30 seconds, then check oil level.

Renew Engine Oil Filter:

- Use a Motorcraft oil filter or equivalent.

- Unscrew old filter with a strap wrench, clean housing face.

- Partly pre-fill new filter with clean oil, apply thin film of oil to sealing ring.

- Screw on new filter until sealing ring abuts filter head, then tighten a further 1/2 turn by hand.

- Run engine, check for leaks, stop, allow oil to settle, and top up.

Fuel Filter - EFI:

- Located between the fuel tank and fuel pump. Maintenance should be performed by an EDI Distributor.

Ignition System - DIS:

- Distributorless Ignition System (DIS) with fixed ignition timing. For alternative fuels, timing can be re-set by trained technicians.

Renew Spark Plugs:

- Located in the top center of the cylinder head. Coil-on-plug design. Access by removing coil retaining bolt and coil.

Electronic Actuator:

- No adjustment can be made if equipped.

Check Condition of Ancillary Drive Belts:

- Engine must be stopped and remote starter disabled.

- Serpentine belt is automatically tensioned.

- Visually inspect for wear or damage; renew if necessary.

Check Engine Coolant Level:

- Allow engine to cool to 40°C (110°F).

- Turn radiator expansion/degas tank filler cap 90° counter-clockwise, pause to release pressure, then remove fully.

- Coolant level is indicated by molded marks on the tank wall. Top up with a 50% plain water and 50% Motorcraft Premium Gold coolant mixture.

- CAUTION against adding cold coolant to an overheated engine to prevent damage.

- WARNING against removing the pressure relief cap while the engine is hot or running.

- WARNING: Antifreeze contains mono ethylene glycol and is toxic. Avoid ingestion and skin contact. Use protective clothing for frequent handling.

Draining, Flushing and Filling the Cooling System:

- WARNING against removing the pressure relief cap while the engine is hot or running.

- Release pressure from the cap, then remove it.

- Remove radiator expansion/degas tank filler cap, open drain cock or detach bottom hose.

- Flush system with water until clean, drain, then close drain cock.

- Fill system slowly with correct coolant mixture to the 'maximum' mark.

- Run engine and check for leaks, top up if necessary.

Engine Lubrication System:

- Regular maintenance is crucial. Dipstick provides a guide to oil condition; dark oil doesn't necessarily mean inadequate changes, but sludge indicates a need for change.

Electrical System (GCP - Power Distribution Box):

- A negative earth (negative ground) system is used.

- The GCP box contains fuses for Battery Voltage to EPR (10A), Ignition Voltage to GCP and Relays (5A), Battery Voltage to GCP (10A), Fuel pump (15A), and Battery Voltage out of Power Relay (15A). One slot is not used.

Generator:

- Mounted at the front of the engine, driven by a serpentine belt.

- Charging rate is automatically adjusted by a built-in regulator.

- Requires no lubrication or maintenance.

- WARNING: Do not remove wiring connections to the generator while the engine is running to prevent damage or personal injury.

Storage:

- Fuel Stabilizer: Highly recommended (Ford Part Number E8AZ-19C544-A or equivalent) for any storage length, especially if fuel won't be consumed within 30 days. Ratio: 2 oz. stabilizer to 5 gallons of gasoline.

- One Month Storage: Add fuel stabilizer. Treat upper cylinders with fogging agent while engine is running. Leave spark plugs in holes or seal them, cover all openings. If less transmission, spray flywheel and ring gear with oil/solvent mixture. Check coolant protection. Store indoors.

- Indefinite Period Storage: Add fuel stabilizer. Drain crankcase and refill with recommended engine oil (SAE 10). Run engine until completely out of fuel (gasoline only: restart and run on unleaded gasoline mixed with stabilizer for at least 10 minutes, then treat upper cylinders with fogging agent). Check coolant protection. Disconnect and remove battery. Clean exterior. Seal spark plug holes and all engine/accessory openings with non-hygroscopic material. Mask electrical contacts. Spray taped openings, accessories, ignition wiring, and exterior surfaces with Insulation Compound. If equipped with automotive clutch, block clutch in slightly disengaged position.

Engine System Check (Troubleshooting):

Provides tables for common symptoms and possible causes for "Engine Performance - No Load," "Engine Performance - While Under Load," and "Engine Concerns" (Oil System, Cooling System, Exhaust System, Fuel System, Engine Noise). This helps operators diagnose issues such as engine not cranking, cranking but not starting, running poorly, cranking slowly, stalling/quitting, running rough, misses, hesitation/stumble, surge, backfires, lack of power, spark knock, high oil consumption, visible smoke, and engine noise.