Forming Difficulties Formech FM660

The purpose of the following section is to help the user in overcoming some problems frequently

encountered in thermoforming. Please remember that the majority of thermoforming faults are caused

by incorrect machine setting or poor mould design.

This section is a guide only and cannot impart the practical experience and skill that any user will

eventually attain. You can find a more comprehensive trouble-shooting guide in the Formech training

Manual located in the support section of the Formech web page. www.formech.com

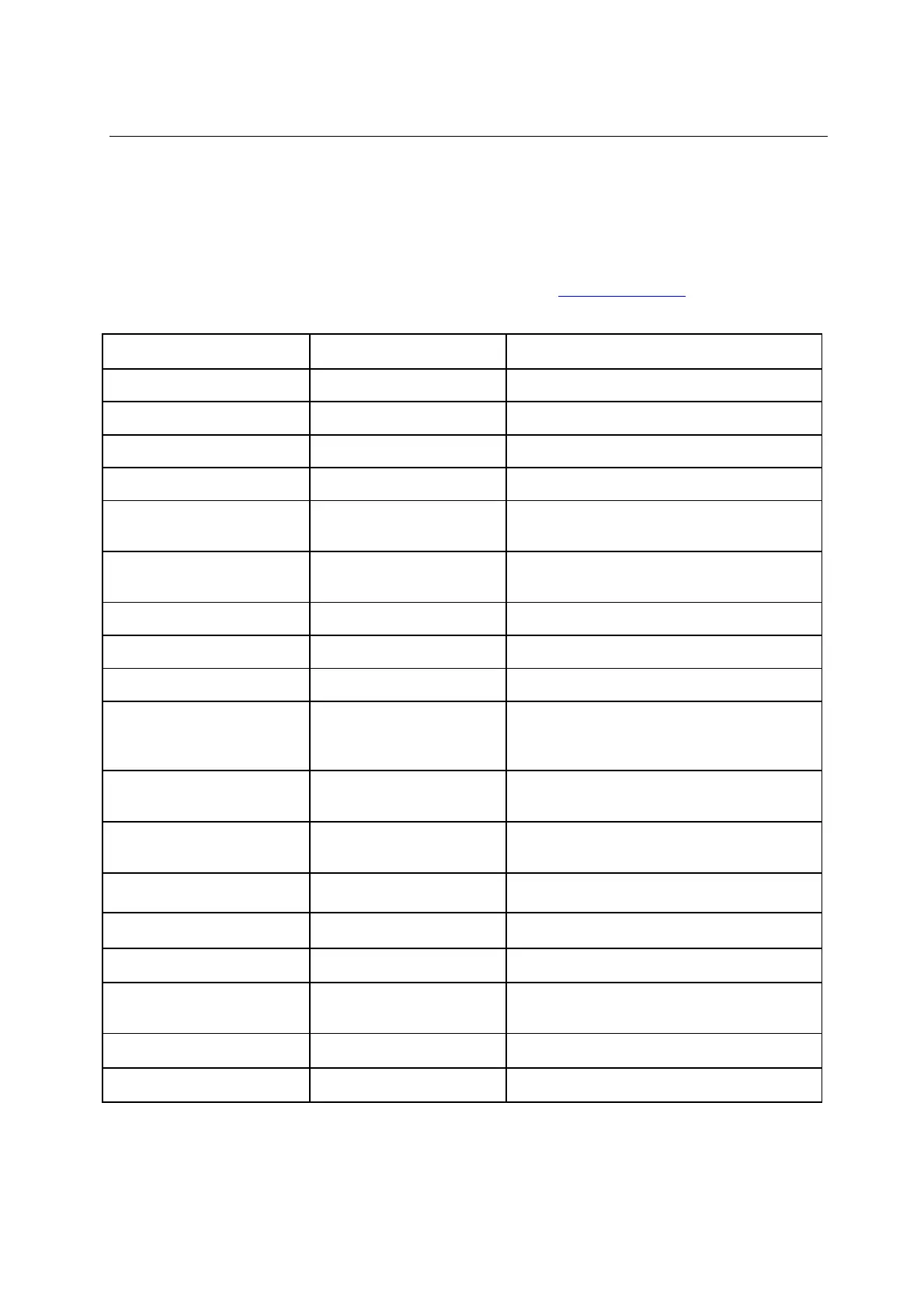

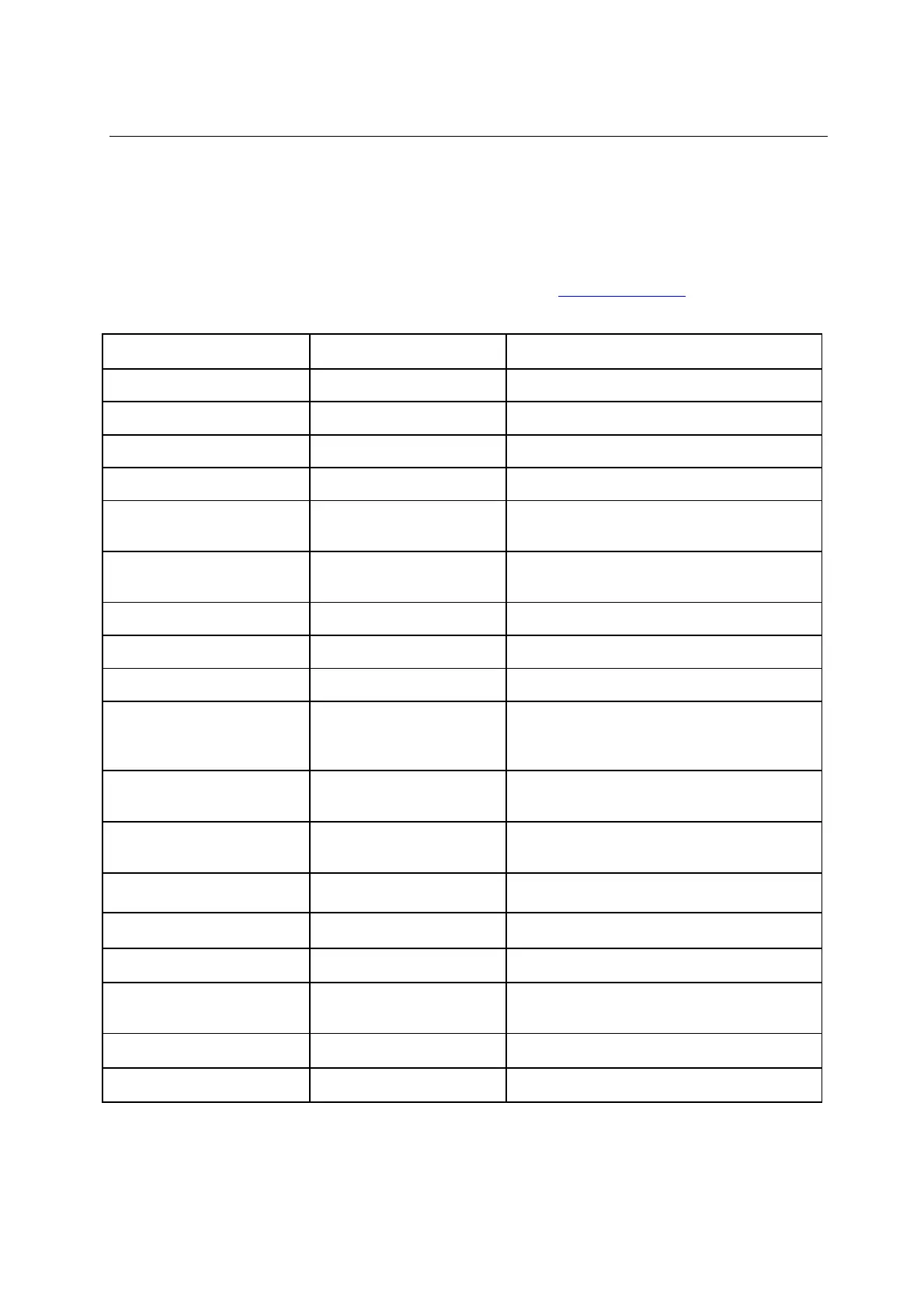

Increase heating time/temp.

Check vent holes on mould

Is mould restricting vacuum flow? Are

vacuum tracks in mould adequate?

Webbing (small pleats at

corners of mouldings)

Incorrect pre-stretch

height

Adjust pre-stretch flow and/or time. Check

panels for leaks

Increase tapers or radii. Use plug assist.

Move cavities further apart (Multiple

moulds)

Reduce material size or use 'dummy'

moulds

Shrinkage of moulding

(after removal from mould)

Product removed from

mould too quickly

Increase timings to allow longer mould

contact

Moulding too thin in areas

Decrease temperature in problem zones

Check elements are working. Are there

any draughts?

Loading...

Loading...