4

CT-200

Under Sink Chiller Unit Installation Instructions and Use and Care Guide

LOCATION REQUIREMENTS

Determine where the chiller and all components being used in the installation should be mounted beforehand

and make sure there is adequate clearance for plumbing and electrical components and there is enough

tubing to reach the intended mounting positions. For best performance, position the chiller to allow a 2" (5 cm)

space around the top and sides. Do not put any objects on top of the chiller that could obstruct the fan.

ELECTRICAL REQUIREMENTS

A 120-volt, 60-Hz, 15- or 20-amp, grounded electrical supply is

required. It is recommended that a separate circuit serving only

your chiller unit be provided. Use an outlet that cannot be

turned on/off by a switch.

RECOMMENDED GROUND METHOD

The chiller must be grounded. This appliance is equipped with

a power supply cord with a 3 prong ground plug. To minimize

possible shock hazard, the cord must be plugged into a mating,

3 prong, ground-type outlet, grounded in accordance with all

national and local codes and ordinances. If a mating outlet is

not available, it is the personal responsibility and obligation

of the customer to have a properly grounded, 3 prong outlet

installed by a qualified electrician.

ELECTRICAL SHOCK HAZARD

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can

result in death, fire, or electrical shock.

WATER SUPPLY REQUIREMENTS

A cold water supply with a minimum pressure of 30 psi and a maximum pressure of 100 psi must be available

to the chiller. It can come directly from the water supply of the home, or from a water filtration system. A

Franke filtration system is highly recommended.

INSTALLATION INSTRUCTIONS

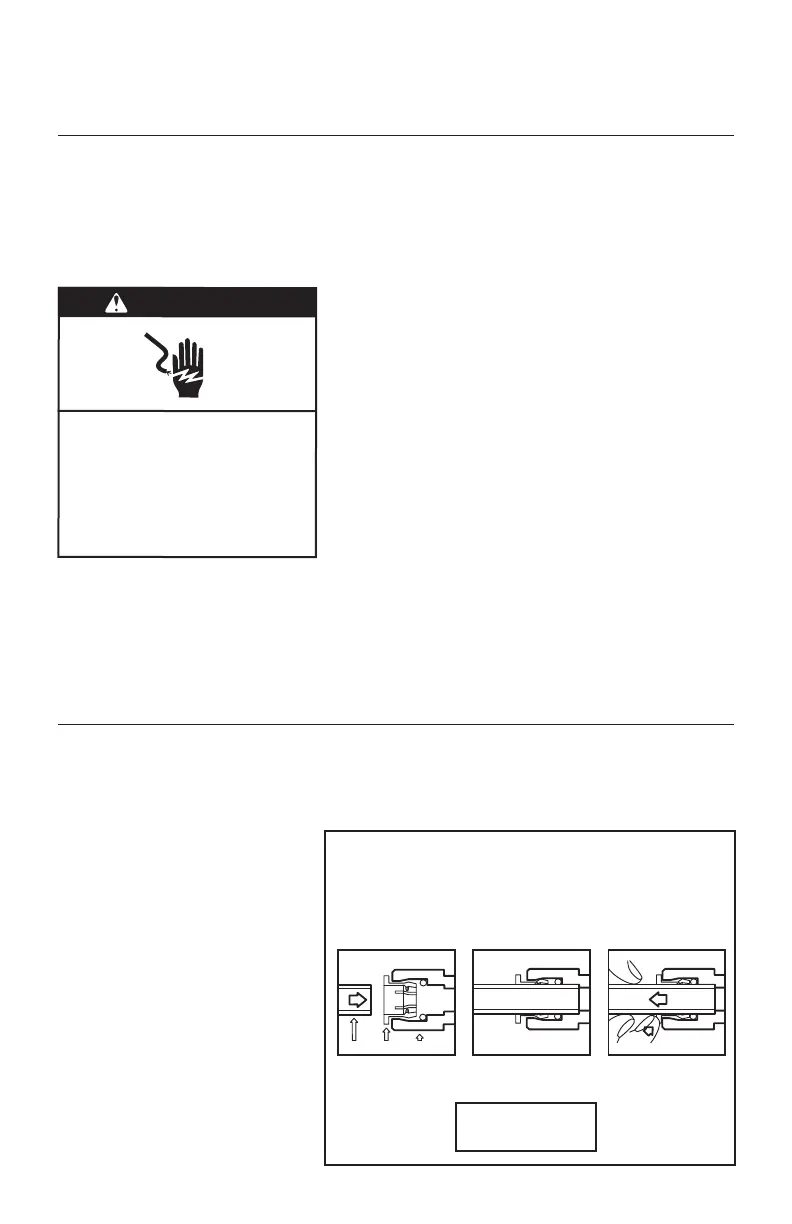

IMPORTANT: For subsequent steps, it will be required to cut and route tubing to fit the specific application in

your home. All tubing must be cut squarely and free of burrs. Ensure there is no damage within 1" of the cut end.

DO NOT USE ANY FORM OF SEALING

COMPOUNDS, this is not required for

push fit connections, and using sealing

compounds could cause leaks. All

tubing connections must be firmly

seated. Tubing must be routed to avoid

sharp bends and have enough slack to

avoid straining connections. A P-clip

and mounting screw is included to

hold the tubing in place as needed.

Pull gently on each connection to

make sure they are secure. See

Diagram 1 for details on tubing

installation and removal.

HOW TO INSERT/REMOVE TUBING

IN PUSH FIT CONNECTIONS

DIAGRAM 1

Loading...

Loading...