12

PUMPTEC-PLUS Pump Protection System

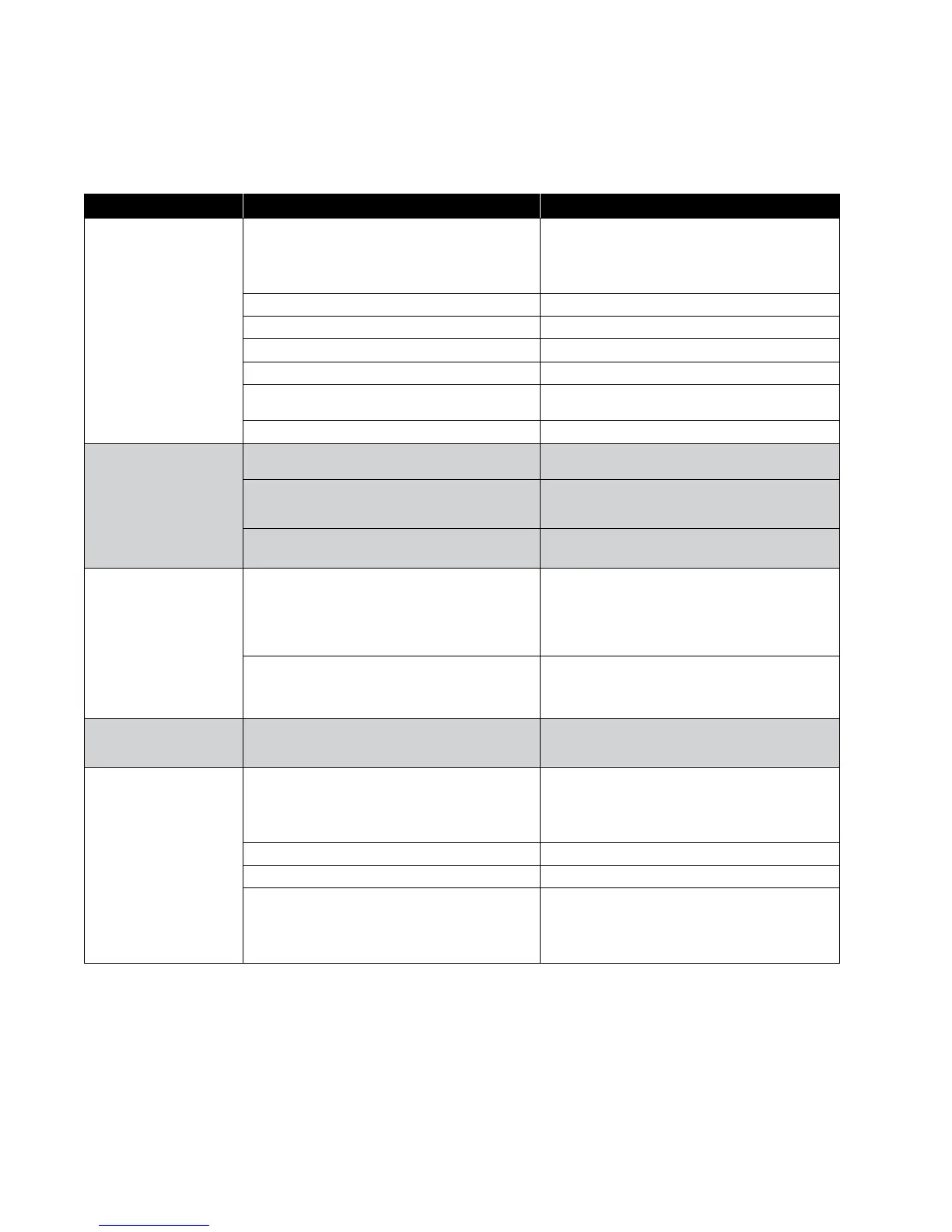

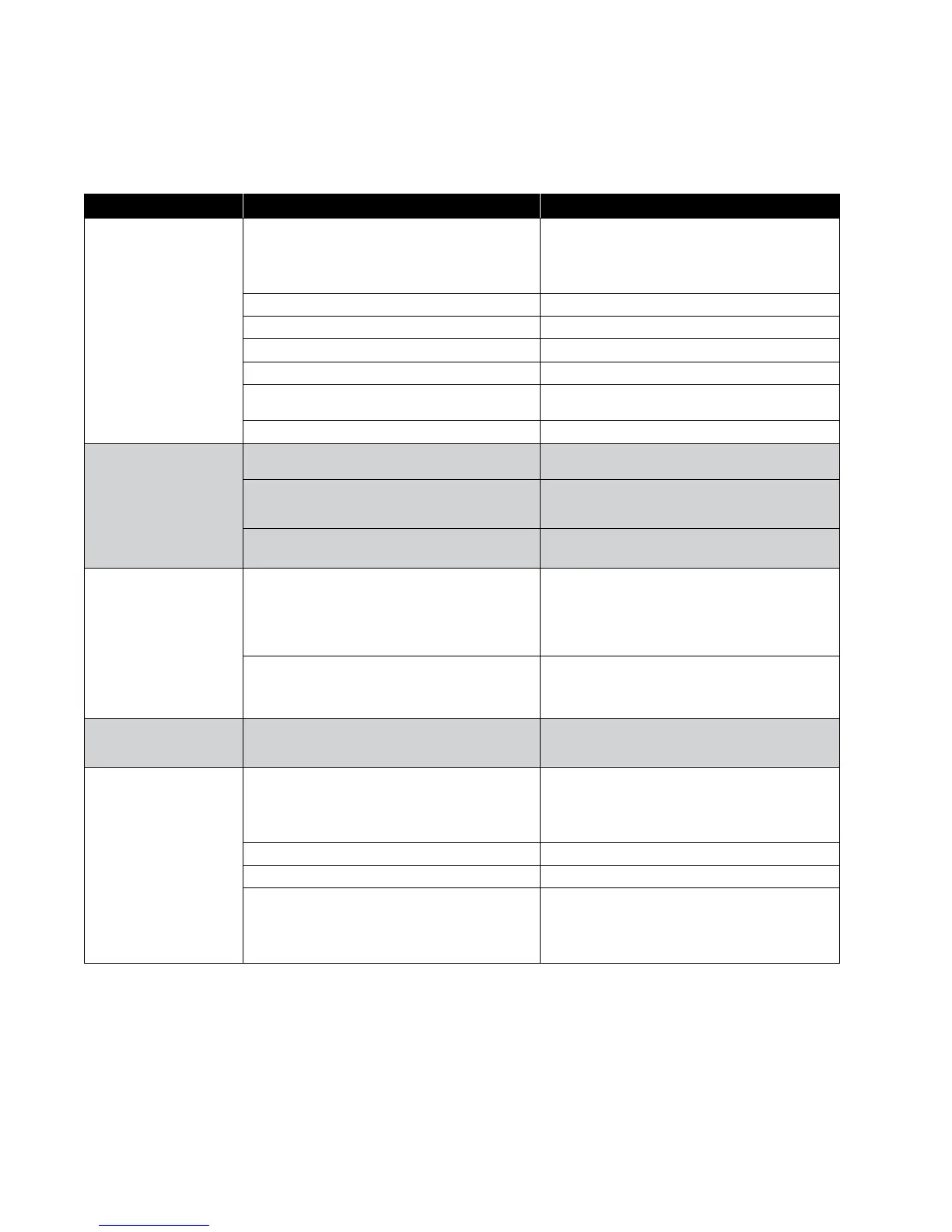

Troubleshooting After Installation

Symptom Possible Cause Solution

Solid Yellow Light

Dry Well

Wait for the automatic restart timer to time out. During

the time out period the well should recover and ll with

water. If the automatic reset timer switch is set to the

manual position, then the reset button must be pressed to

reactivate the unit.

Blocked Intake Clean or replace pump intake screen.

Blocked Discharge Remove blockage in plumbing.

Check Valve Replace check valve.

Broken Shaft Replace broken parts.

Severe Rapid Cycling

Machine gun rapid cycling can cause an underload

condition. See ashing red and yellow lights section below.

Worn Pump Replace worn pump parts and recalibrate.

Flashing Yellow Light

Stalled Motor

Repair or replace pump motor. Pump may be sand or mud

locked.

Float Switch

A bobbing oat switch can cause two-wire motors to stall.

Arrange plumbing to avoid splashing water. Replace oat

switch.

Ground Fault

Check insulation resistance on motor and control box

cable.

Solid Red Light

Low Line Voltage

Step C of the calibration instructions indicates that a

ashing green light condition will occur 2 to 3 seconds

after taking the Snapshot of the motor load. On some two-

wire motors, the yellow light will ash instead of the green

light. Press and release the reset button. The green should

start ashing.

Loose Connections

Check for excessive voltage drops in the system electrical

connections (i.e. circuit breakers, fuse clips, pressure

switch, and Pumptec-Plus L1 and L2 terminals). Repair

connections.

Flashing Red Light High Line Voltage

The line voltage is over 253 Volts. Check line voltage.*

The Pumptec-Plus will try to restart the motor every two

minutes until line voltage is normal.

Flashing Red And

Yellow Lights

Rapid Cycle

The most common cause for the rapid cycle condition is

a waterlogged tank. Check for a ruptured bladder in the

water tank. Check the air volume control or snifter valve for

proper operation. Check the setting on the pressure switch

and examine for defects.

Leaky Well System Replace damaged pipes or repair leaks.

Stuck Check Valve Failed valve will not hold pressure. Replace valve.

Float Switch

Press and release the reset button to restart the unit. A

bobbing oat switch may cause the unit to detect a rapid

cycle condition on any motor or an overload condition on

two-wire motors. Try to reduce water splashing or use a

dierent switch.

*Report high or low line voltage to the power company.

Loading...

Loading...