zero and the primary relief valve will open almost

immediately after fueling, allowing excess LNG vapor

to escape. If fueling is stopped when the ullage tank

is empty (i.e., the fuel tank has sufficient vapor space

to accommodate fuel expansion due to temperature

increase), the vehicle will have approximately one

week of standby time before venting will occur.

Use the following steps to fuel an LNG vehicle.

1.

Shut down the engine and apply the parking

brake.

IMPORTANT: Close all windows and doors dur-

ing the fueling process. Keeping windows and

doors closed allows for easier leak detection

inside the cab after fueling.

WARNING

Liquefied natural gas is a cryogenic liquid stored

at approximately -259°F (-162°C). Cryogenic

burns can be caused by coming into contact with

the pressurized liquid stream, or by coming into

contact with fuel system components that have

been cooled to cryogenic temperatures. Always

wear gloves and a face shield, and cover ex-

posed skin when fueling.

2.

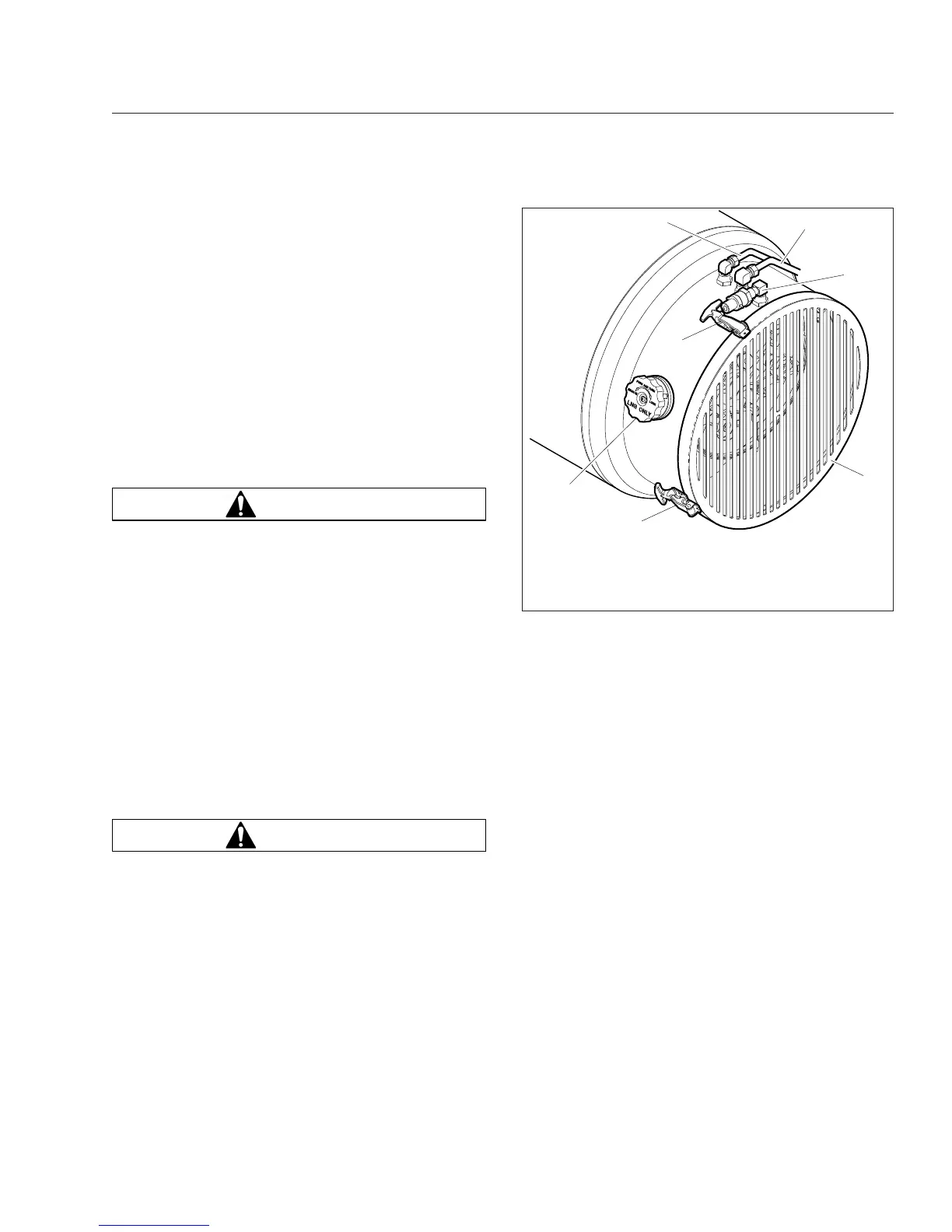

Remove the fuel fill fitting dust cap. See

Fig. 19.2.

3.

Using compressed air, remove any dirt, debris, or

water that may have collected in the fuel fill fit-

ting and the station dispensing nozzle. Contami-

nants in the fuel system can cause drivability

problems.

WARNING

Natural gas fuel tanks, lines, and valves are al-

ways pressurized. Always observe safety precau-

tions. Failure to do so could lead to loss of con-

trol over a filling hose or to ignition of the natural

gas, which could cause serious bodily injury,

death, or severe property damage.

4.

Connect the station fueling nozzle to the tank

fuel fill fitting.

5.

Connect an electrical ground clamp and cable to

the fuel tank.

IMPORTANT: An LNG tank which is first in-

stalled, or is on a vehicle that has not been op-

erated in approximately ten days, is considered

to be a hot tank. When fueling a hot tank, LNG

entering the tank will immediately vaporize,

causing tank pressure to spike above 250 psi

(1724 kPa) and automatically shutting down the

station fuel pump. To prevent the pump from

shutting down, connect a vent line to the fill vent

fitting on the LNG tank to capture escaping

vapor, then open the shroud cover and open the

vapor shutoff valve (

Fig. 19.3, Item 2).

6.

Open the station’s fill valve, if equipped, and

start fueling. Monitor the flow or line pressure as

filling progresses. When filling begins, line pres-

sure will spike quickly until the vehicle tank cools

down. The flow and pressure will then remain

stable during the remainder of the filling

procedure.

IMPORTANT: When fueling a hot tank, initially

put 5 to 10 gallons (19 to 37 liters) of LNG in

the tank and manually stop the fueling process.

Drive the vehicle for 15 to 20 minutes to cool

the tank and reduce tank pressure, then con-

tinue fueling the tank to full.

05/29/2009 f470534

1

2

3

4

6

5

6

1. Fuel Fill Fitting

2. Fuel Outlet Line

3. Primary Relief Vent

Line

4. Fill Vent Fitting

5. Shroud Cover

6. Shroud Cover Latches

Fig. 19.2, LNG Fuel Tank

Natural Gas Vehicle

19.4

Loading...

Loading...