Hendrickson Suspension

Torque Values

Description Size

Torque

lbf·ft (N·m)

Fore and Aft Torque

Rod Mount Nut

— 95 (130)

Table 2, Hendrickson Suspension Torque Values

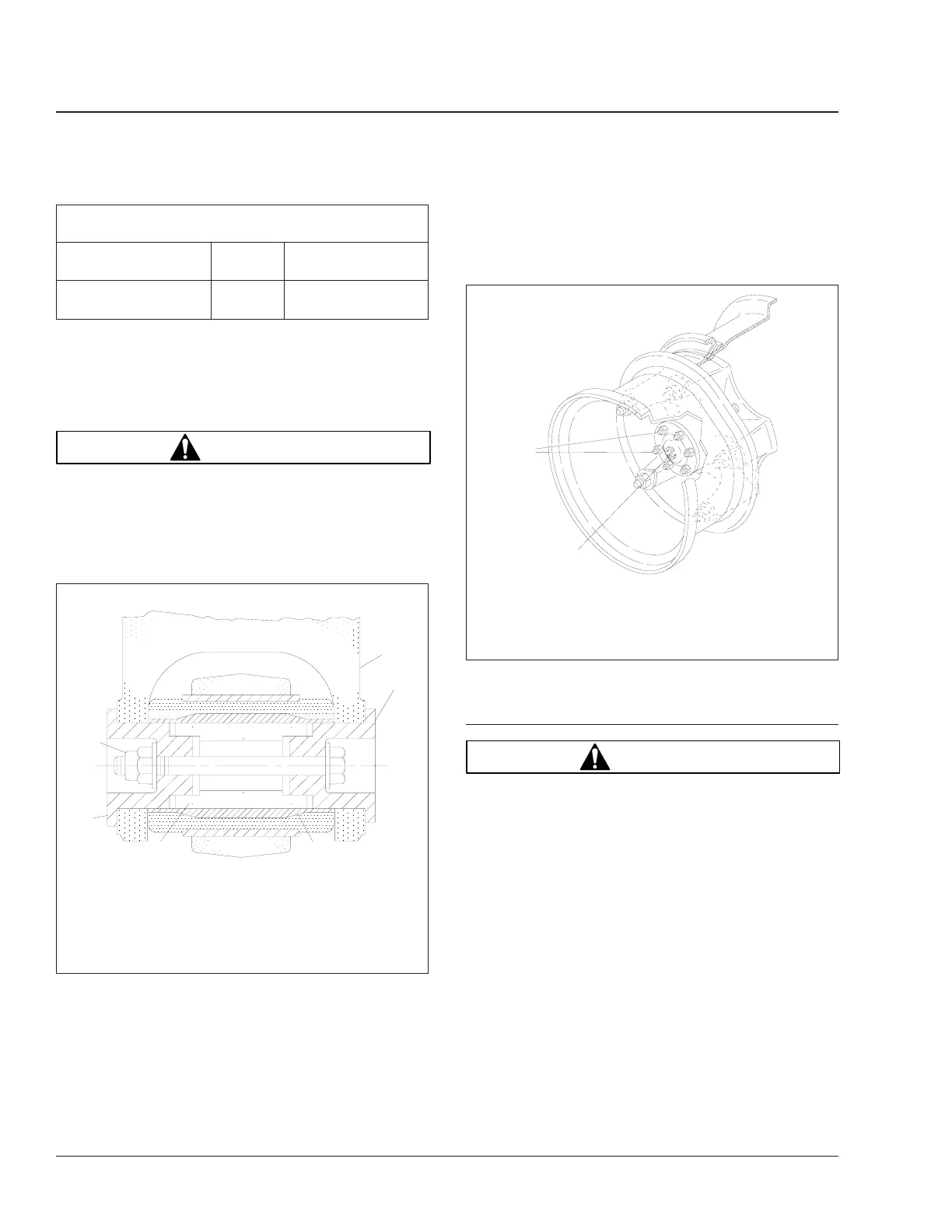

All Hendrickson beam end fasteners must maintain

their torque values to firmly clamp the rubber bushing

inner metal tubes to the beam hanger legs.

WARNING

Insufficient beam end fastener torque could cause

the beam to separate from the axle, and result in

loss of vehicle control.

Tighten the nut (see Fig. 1) to the torque value in

Table 2. Do not over-torque.

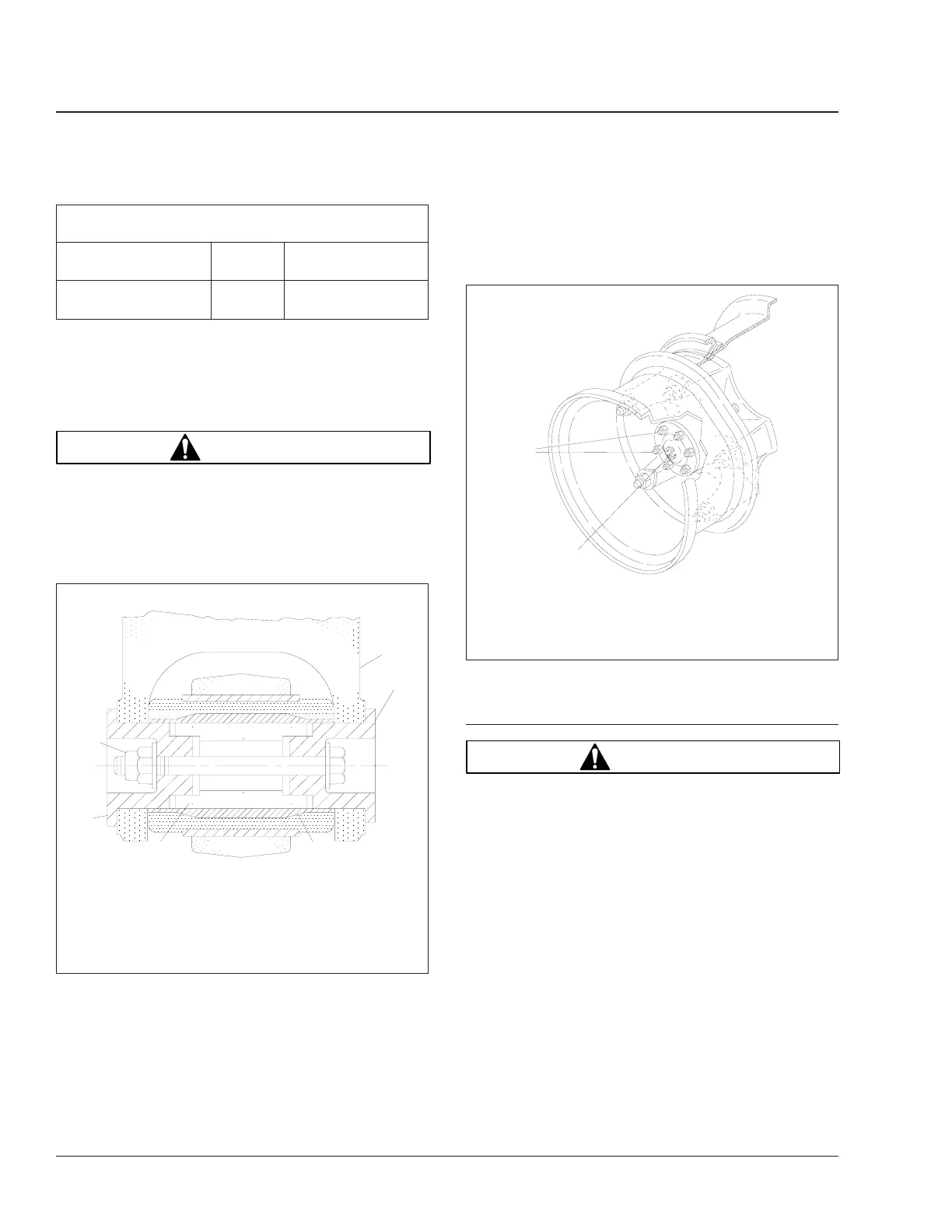

Check the drive-axle-flange fasteners (Fig. 2) for

tightness. Tighten the fasteners as follows:

Tighten 1/2-inch drive-axle stud nuts (with or without

dowels) 75 to 115 lbf·ft (102 to 156 N·m), and tighten

5/8-inch drive-axle stud nuts 150 to 230 lbf·ft (203 to

312 N·m).

31–02 Fifth Wheel Inspecting

WARNING

All fifth wheel maintenance, adjustment, and re-

building must be done only by a qualified me-

chanic. Improper or incomplete procedures could

result in possible disengagement of the trailer

from the tractor, causing serious damage or injury.

Wear safety goggles during removal, installation,

and rebuilding. Failure to do so can result in per-

sonal injury, due to parts ejecting under spring

compression.

Fontaine

Disconnect the tractor from the trailer. For instruc-

tions, see Chapter 10 of the

Business Class

®

Trucks

Driver’s Manual

. Thoroughly steam clean the fifth

wheel, then make the following checks:

1. Look for cracks in the fifth wheel assembly,

mounting brackets, and mounting parts.

f320110a

05/27/93

1

2

2

3

4

5

NOTE: Do not use the three-piece adapter without the

intermediate tube.

1. Nut

2. Adapter

3. Intermediate Tube

4. Inner Metal of Beam

End Bushing

5. Beam Hanger

Fig. 1, Three-Piece Adapter-Type Beam End Connection

06/09/94

f400090b

1

2

NOTE: Spoke wheel shown.

1. Drive-Axle-Flange

Studs and Nuts

2. Drive-Axle Flange

Fig. 2, Drive-Axle Flange

Frame and Frame Components31

Business Class Trucks Maintenance Manual, December 200231/2

Loading...

Loading...