when inflated. If the clearance is less than 1 inch (25

mm), relocate the obstructing parts.

CAUTION

Failure to relocate obstructing parts could result

in damage to the air spring.

Freightliner AirLiner Component

Inspecting and Operation Checking

WARNING

Inspect the components and check their operation

as described below. Failure to perform these in-

spections and checks could result in separation of

worn suspension components and loss of vehicle

control resulting in property damage, serious per-

sonal injury or death.

1. Chock the front tires. Raise the rear of the ve-

hicle so the tires just clear the ground and the

suspension is fully extended. Place safety stands

under the vehicle frame.

2. Squeeze all air springs to check for complete

deflation. If any air springs remain partially or

fully inflated, see Group 32 of the

Business

Class

®

Trucks Service Manual

.

3. Inspect each air spring for wear at its connection

to its pedestal. Replace any worn air springs; for

instructions, see Group 32 of the

Business

Class

®

Trucks Service Manual

.

4. Check the axle connection welds (beam-seat to

equalizing-beam) and axle-adapter to axle for

cracks. If welds are cracked, grind them out and

reweld the parts.

5. Move the axle up and down while checking for

signs of looseness due to worn parts at the front

pivot connections. Replace any worn parts by

following the procedures in Group 32 of the

Business Class

®

Trucks Service Manual

.

6. Inspect the shock absorbers for oil leaks and

worn rubber bushings. Replace the shock ab-

sorbers and/or rubber bushings if wear or dam-

age is noted. For instructions, see Group 32 of

the

Business Class

®

Trucks Service Manual

.

7. Remove the safety stands and lower the rear of

the vehicle to the ground. Run the engine until

air pressure of at least 100 psi (689 kPa) is

maintained throughout the system.

8. Check that all air springs are inflated. If the air

springs do not inflate, see Group 32 of the

Busi-

ness Class

®

Trucks Service Manual

for possible

causes and corrections.

Freightliner AirLiner Control Rod

Checking

1. Without disconnecting the control rods, attempt

to move (by hand) each of the control rod ends

up, down, in, and out. If there is any movement,

examine the control rods for wear or damage.

Replace if necessary.

2. Inspect the rubber bushings for cracks or cuts.

3. Check for any shifting of the barpin.

4. Check for cracks in the metal components and

welds.

NOTE: The Freightliner AirLiner Suspension is

manufactured at numerous weight ratings up to

46,000 pounds. The control rod on the 46,000-

pound-rated suspension is larger, and is fas-

tened differently than on other applications; see

Group 32of the

Business Class

®

Trucks Service

Manual

for removal and installation information.

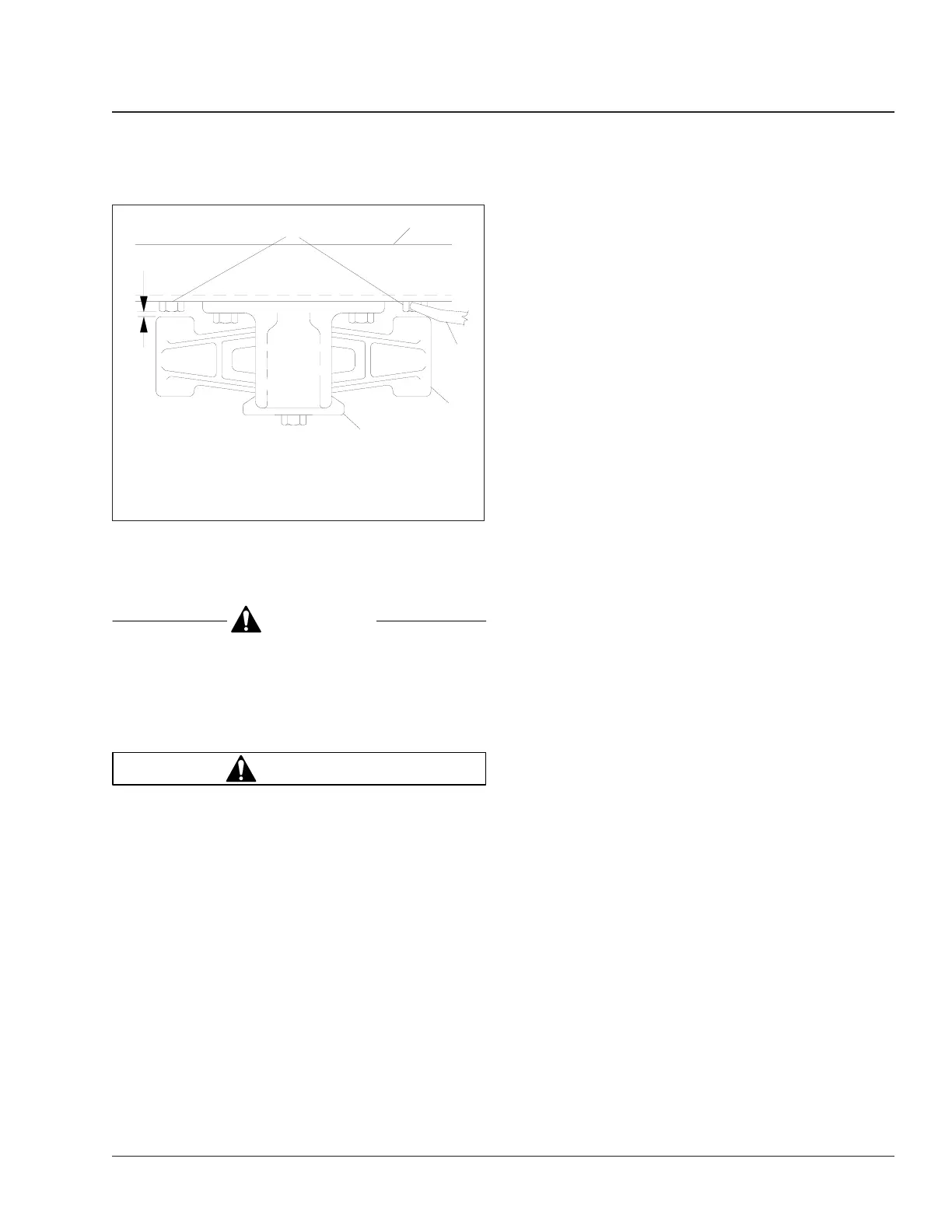

f320023a

05/27/93

1

2

3

4

5

A

A. 1/8 inch (3 mm) Clearance

1. Frame Fasteners

2. Frame Rail

3. Pry Bar

4. Equalizer

5. Equalizer Bracket

Fig. 4, Top View of the Equalizer

Suspension 32

Business Class Trucks Maintenance Manual, July 1999 32/3

Loading...

Loading...