• There are gaps between the rubber bush-

ing and the pin or the outer steel sleeve.

• Either bushing end contacts a torque arm

pin mounting bolt.

• There are cracks in the bushing.

• Part of the rubber bushing extends beyond

the outside diameter of the outer bushing

sleeve.

Freightliner Spring (Tandem)

Equalizer Bushing Checking

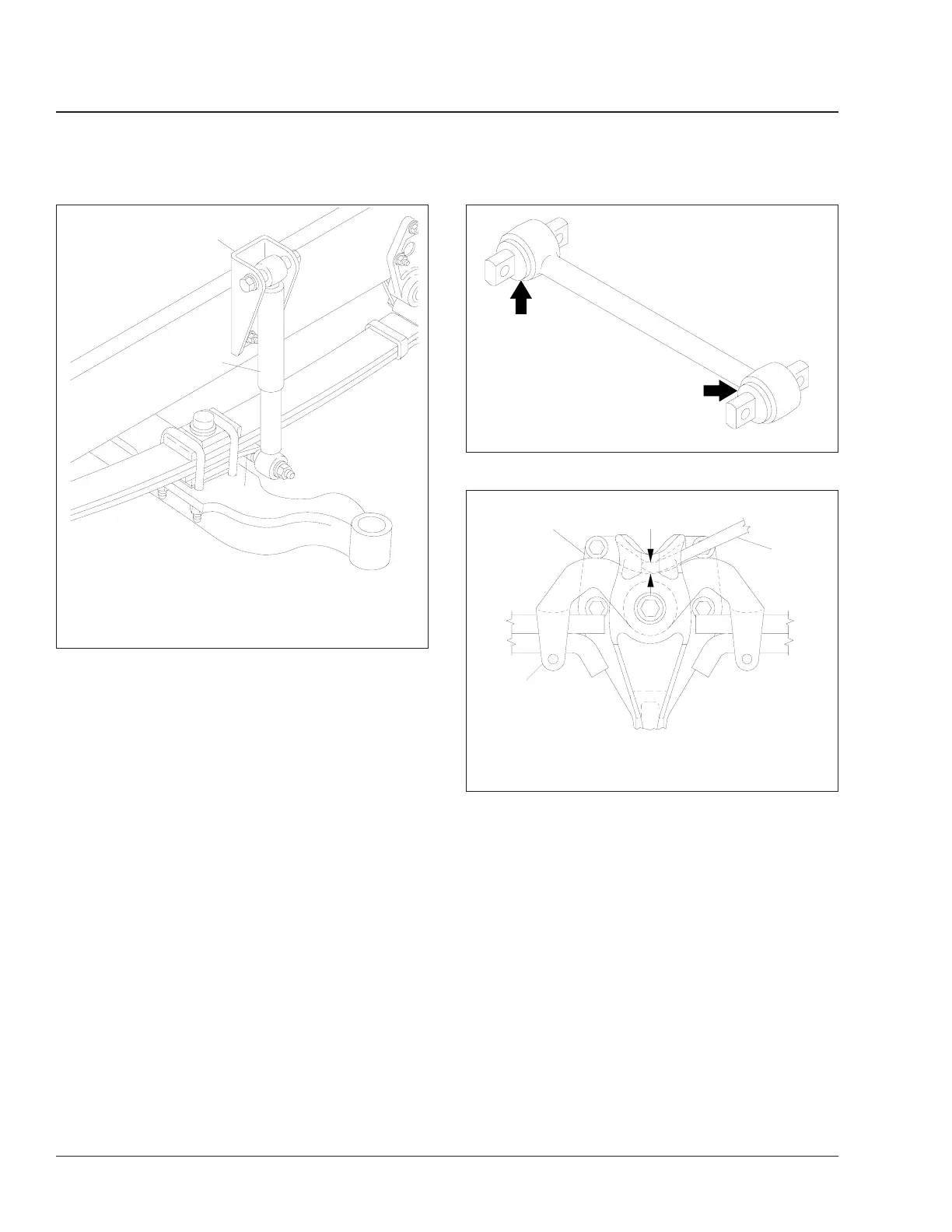

1. Block the frame up enough to take the weight of

the chassis off of the springs. Attempt to move

the equalizer up and down, by using a pry bar

between the top of the equalizer and the top of

the equalizer bracket. Apply hand pressure only.

See Fig. 3. If movement at the center of the

equalizer exceeds 1/8 inch (3 mm), replace the

equalizer bushings.

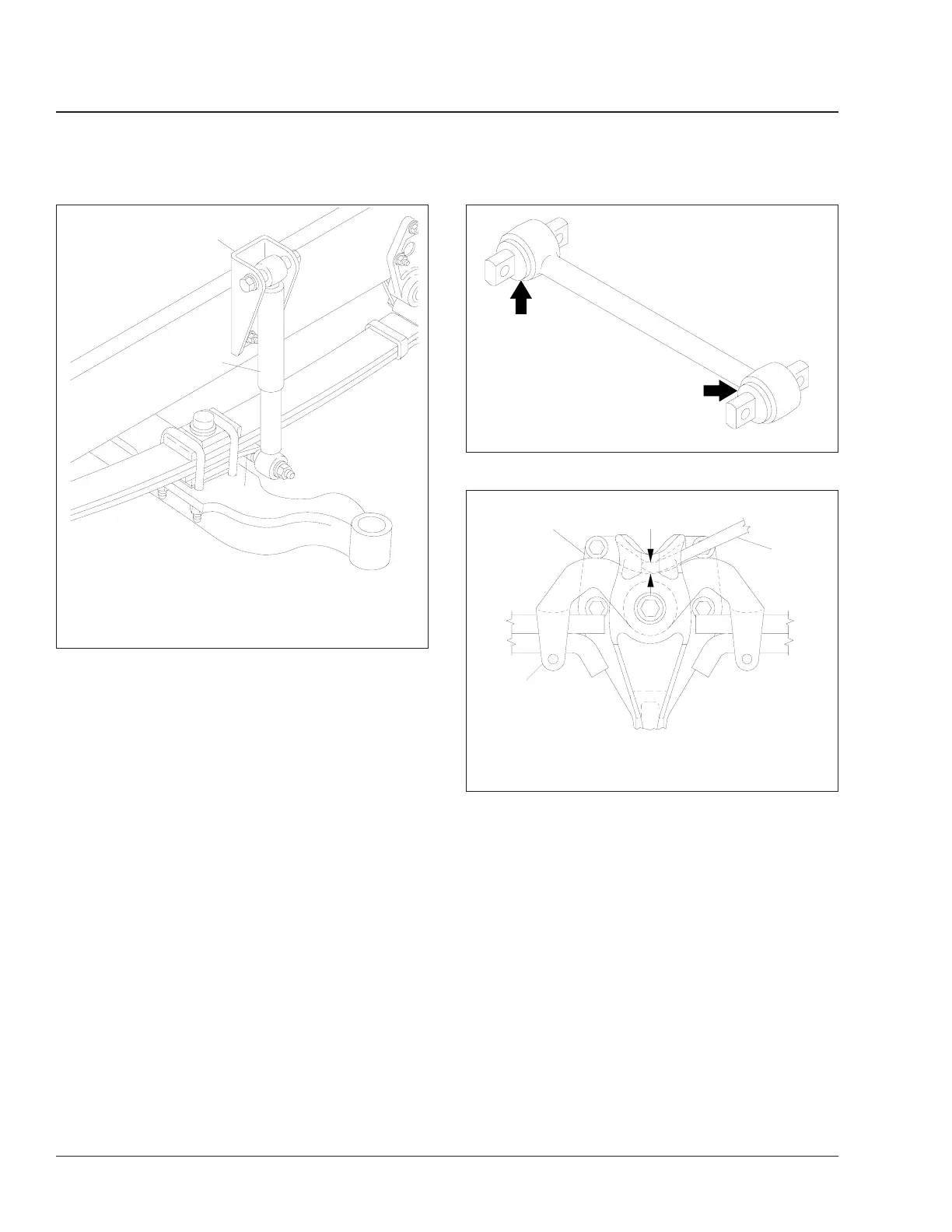

2. With the vehicle unloaded, attempt to move the

equalizer side to side using a pry bar between

the equalizer and frame rail. Apply hand pressure

only. See Fig. 4. If clearance between the equal-

izer assembly and any frame component or fas-

tener is less than 1/8 inch (3 mm), replace the

equalizer bushings.

Freightiner AirLiner Component

Clearance Checking

Check that the air line support brackets are posi-

tioned so the air lines do not rub against anything.

Reposition any configurations that could contact and

result in friction and wear. There must be at least 1

inch (25 mm) clearance around the rubber air spring

f320267a

10/05/94

1

2

3

1. Upper Mounting Bracket

2. Shock Absorber

3. Lower Mounting Bracket

Fig. 1, Shock Absorber Installation (front suspension

shown)

f320021a

05/27/93

Fig. 2, Torque Arm Bushings

f320022a

05/27/93

1

2

3

A

A. Measure the change in gap at this point.

1. Equalizer Bracket

2. Equalizer

3. Pry Bar

Fig. 3, Side View of the Equalizer

Suspension32

Business Class Trucks Maintenance Manual, July 199932/2

Loading...

Loading...