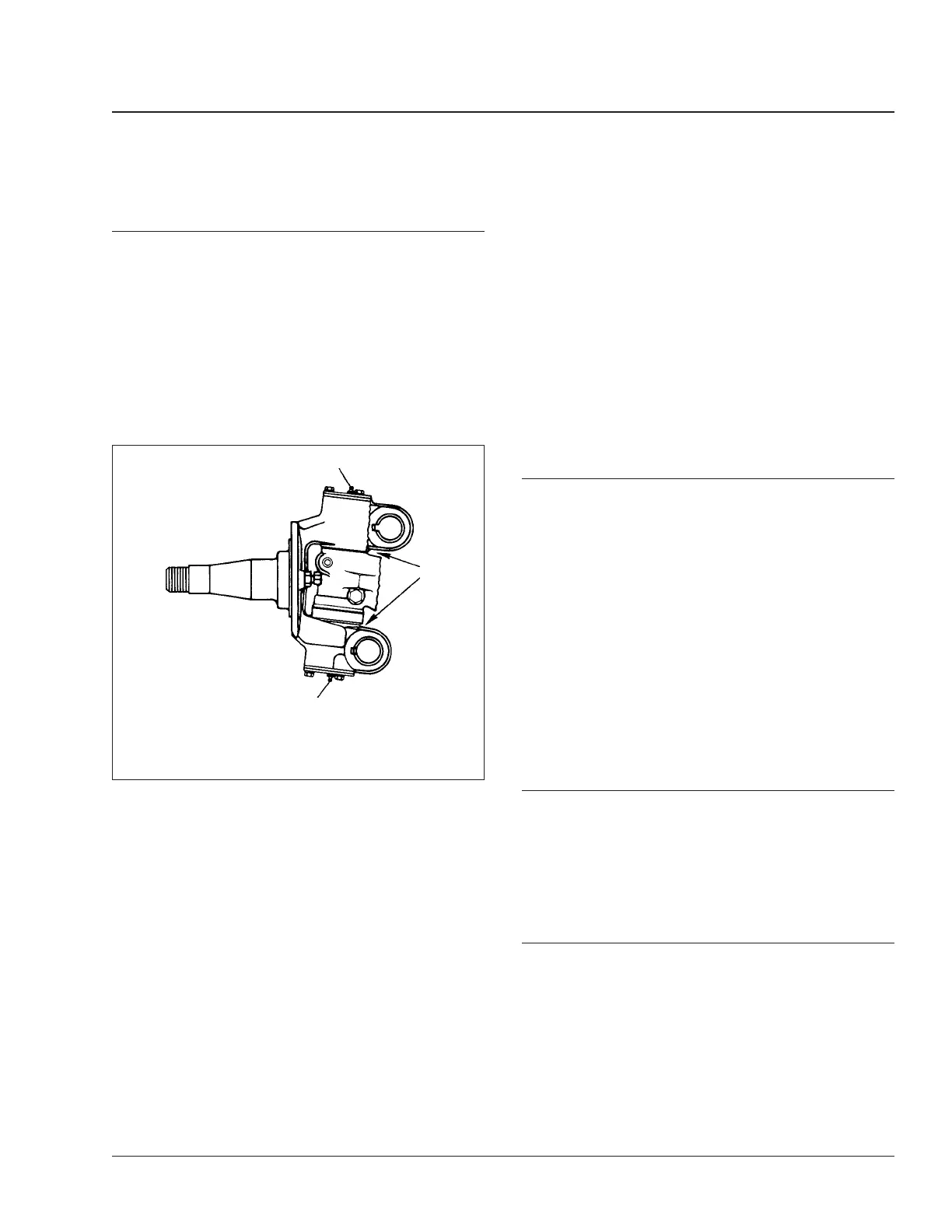

33–01 Knuckle Pin Lubricating

Hold a pressure gun on each fitting until fresh grease

appears. See Fig. 1. This will ensure that all the old

contaminated grease has been forced out. It is not

necessary to exceed 4000 psi (27 560 kPa). The

best distribution of new lubricant and the best purg-

ing of old lubricant occurs when about 4000 psi (27

560 kPa) pressure is applied at the grease gun

nozzle. Using a 40 to 1 booster, the air should be

limited to 100 psi (689 kPa); using a 50 to 1 booster,

the air should be limited to 80 psi (551 kPa). Higher

or lower pressures are not recommended.

When lubricating knuckle pin bushings for Initial

Maintenance, raise the front axle until the front tires

are off the ground. Wipe the lube fittings clean, and

slowly feed multipurpose chassis grease (NLGI grade

1 or 2) into each bushing area while turning the

wheels from extreme right to left and back again

(lock to lock). This will eliminate small air pockets

and improve grease distribution.

Lower the tires to the ground, and regrease both top

and bottom bushings until new grease is seen at the

seal on the bushing opposite the fittings. The grease

seal will accept the grease pressure without damag-

ing the seal, and is designed to have grease pumped

out through it during lubrication. Even if grease leaks

out around the top or bottom plate gasket, continue

pumping until new grease is seen at the seal on the

bushing opposite the grease fitting.

When lubricating knuckle pin bushings at M1 through

M5, do not raise the front axle. Wipe the lube fittings

clean, and apply multipurpose chassis grease until

new grease is seen at the grease seal on the bush-

ing opposite the fittings. The grease seal will accept

the grease pressure without damaging the seal, and

is designed to have grease pumped out through it

during lubrication. Even if grease leaks out around

the top or bottom plate gasket, continue pumping

until new grease is seen at the seal on the bushing

opposite the grease fitting.

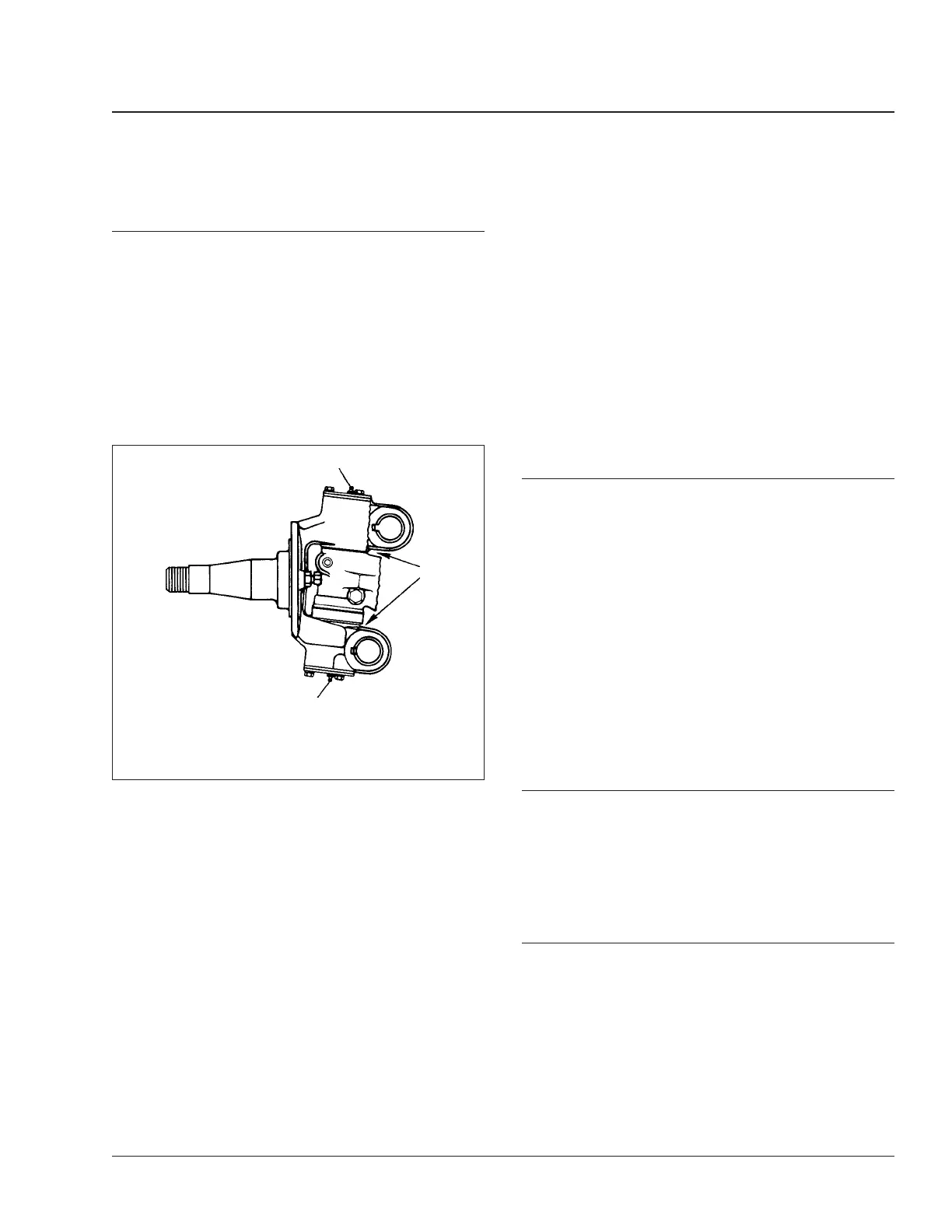

33–02 Tie-Rod End Inspecting

1. Shake the cross-tube. Movement or looseness

between the tapered shaft of the ball and the

cross-tube socket members means that the tie-

rod end assembly must be replaced.

2. The threaded portion of the tie-rod end assembly

must be inserted all the way into the cross-tube

split, for adequate clamping. See Fig. 2. Replace

the parts if this cannot be done. For instructions,

see the axle manufacturer’s service manual.

3. Check the tie-rod end nut and clamp nut torques.

Tighten the tie-rod end nut 100 lbf·ft (136 N·m),

and tighten the clamp nut 40 to 55 lbf·ft (54 to 75

N·m).

33–03 Tie-Rod End Lubricating

Wipe the tie-rod end grease fittings clean, then pump

multipurpose chassis grease (NLGI grade 1 or 2) to

the tie-rod ends until all used grease is forced out

and new grease appears at the ball stud neck.

33–04 All-Axle Alignment

Checking

Drive Axle Alignment Checking

Check the axle alignment, parallelism, and thrust

angle measurements for the rear drive axles. Use the

applicable procedure and specifications in Group 35

of the

Business Class

®

Trucks Service Manual

.

f320032a

1

1

A

10/20/93

A. Pump lubricant into each grease fitting until fresh

grease comes out here.

1. Grease Fitting

Fig. 1, Meritor Front Axle

Front Axle 33

Business Class Trucks Maintenance Manual, June 2001 33/1

Loading...

Loading...