49-01 Exhaust System

Inspecting (Noise

Emission Controls)

NOTE: In addition to the maintenance interval in

this manual, inspect the exhaust system if the

vehicle has a noticeable increase in noise level

at any time. Replace parts that show leakage,

wear, or damage.

1. Check the muffler body, muffler outlet stack, muf-

fler shield, and inlet tubes, for leakage, dents,

corrosion, or holes in the muffler.

2. Inspect the exhaust pipe for leakage, wear, or

damage; replace with new parts, if needed. Do

not reuse wide-band clamps. Once a clamp is

removed, it must be replaced.

2.1 On Caterpillar, Cummins, and Detroit Die-

sel engines, check for leakage at the

V-type clamp that attaches the exhaust

pipe to the turbocharger exhaust outlet. If

leakage exists, tighten the nut on the

V-type clamp 85 lbf·in (940 N·cm). If leak-

age persists, install a new V-band cou-

pling.

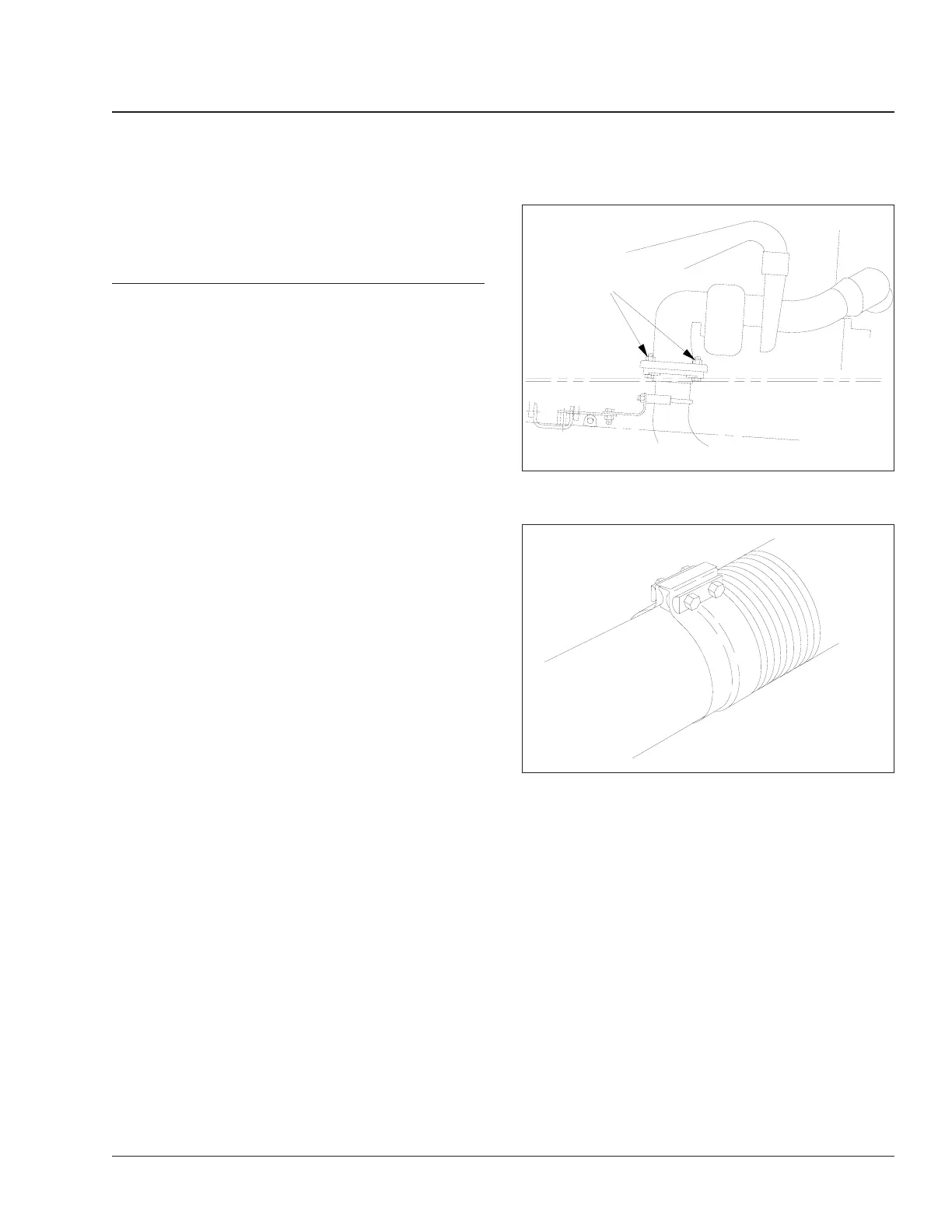

2.2 On Mercedes-Benz OM 366LA and

Dodge Magnum engines, check the tight-

ness of the fasteners that attach the ex-

haust pipe to the exhaust flange (Fig. 1).

If needed, tighten the fasteners 33 lbf·ft

(45 N·m) for Mercedes-Benz OM 366LA

engines. For Dodge Magnum engines,

tighten the fasteners 25 lbf·ft (34 N·m).

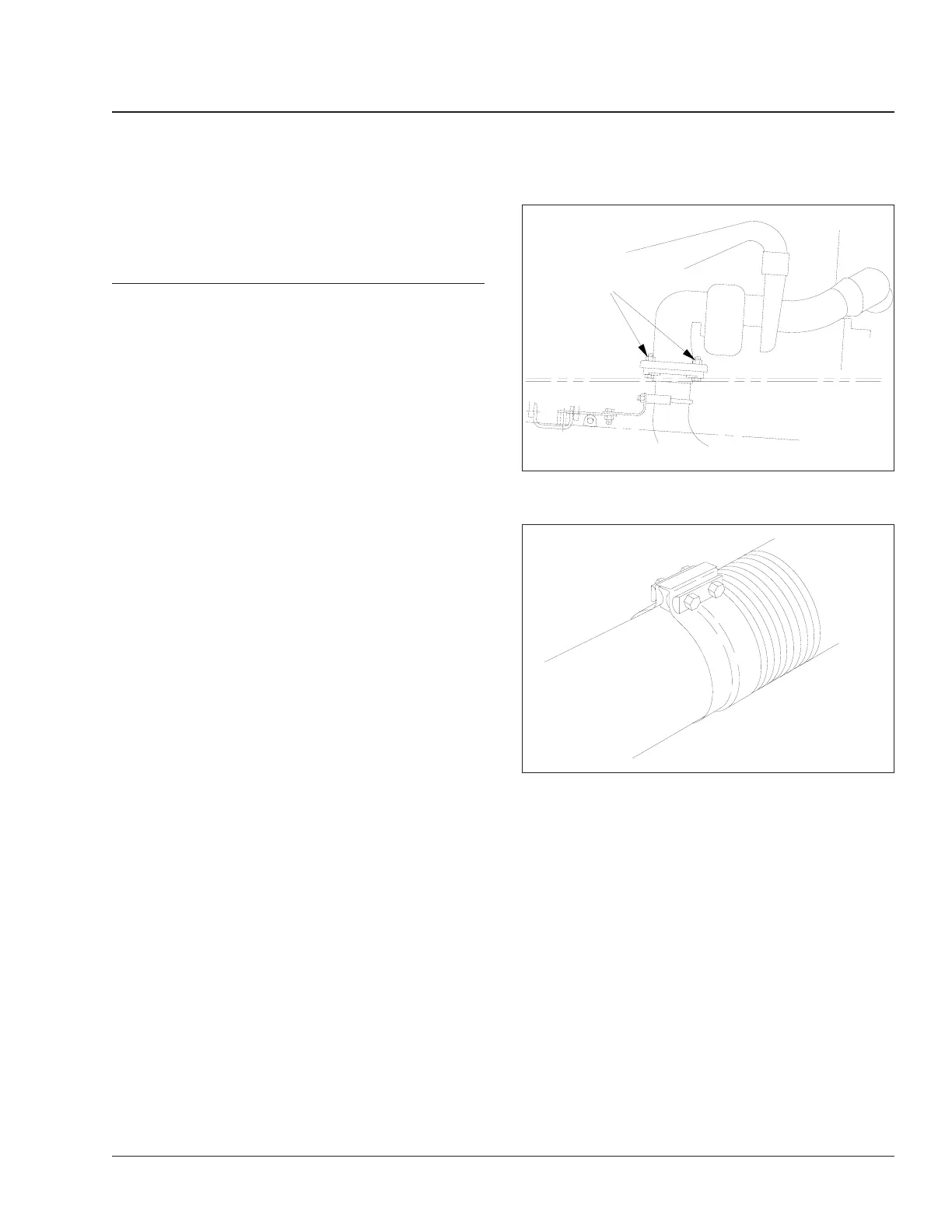

3. Check for leakage at each wide-band exhaust

clamp (Fig. 2). If leakage exists, tighten the nuts

40 to 60 lbf·ft (54 to 81 N·m). If leakage persists,

install a new wide-band exhaust clamp. See

Group 49 of the

Business Class

®

Trucks Service

Manual

for procedures.

f490032a

10/05/94

A

A. Check the Tightness of These Fasteners

Fig. 1, Typical Exhaust-Pipe to Exhaust-Flange

Fasteners, OM 366 Engine Shown

f490005a

10/05/94

Fig. 2, Wide-Band Exhaust Clamp

Exhaust 49

Business Class Trucks Maintenance Manual, October 1998 49/1

Loading...

Loading...