CAUTION

When flushing the radiator, do not apply more

than 20 psi (138 kPa) air pressure. Excessive pres-

sure can damage the radiator or heater core.

4. Drain the radiator, and flush the radiator until

clean water flows from the radiator. Remove the

flushing gun.

5. Close the petcock at the bottom of the radiator.

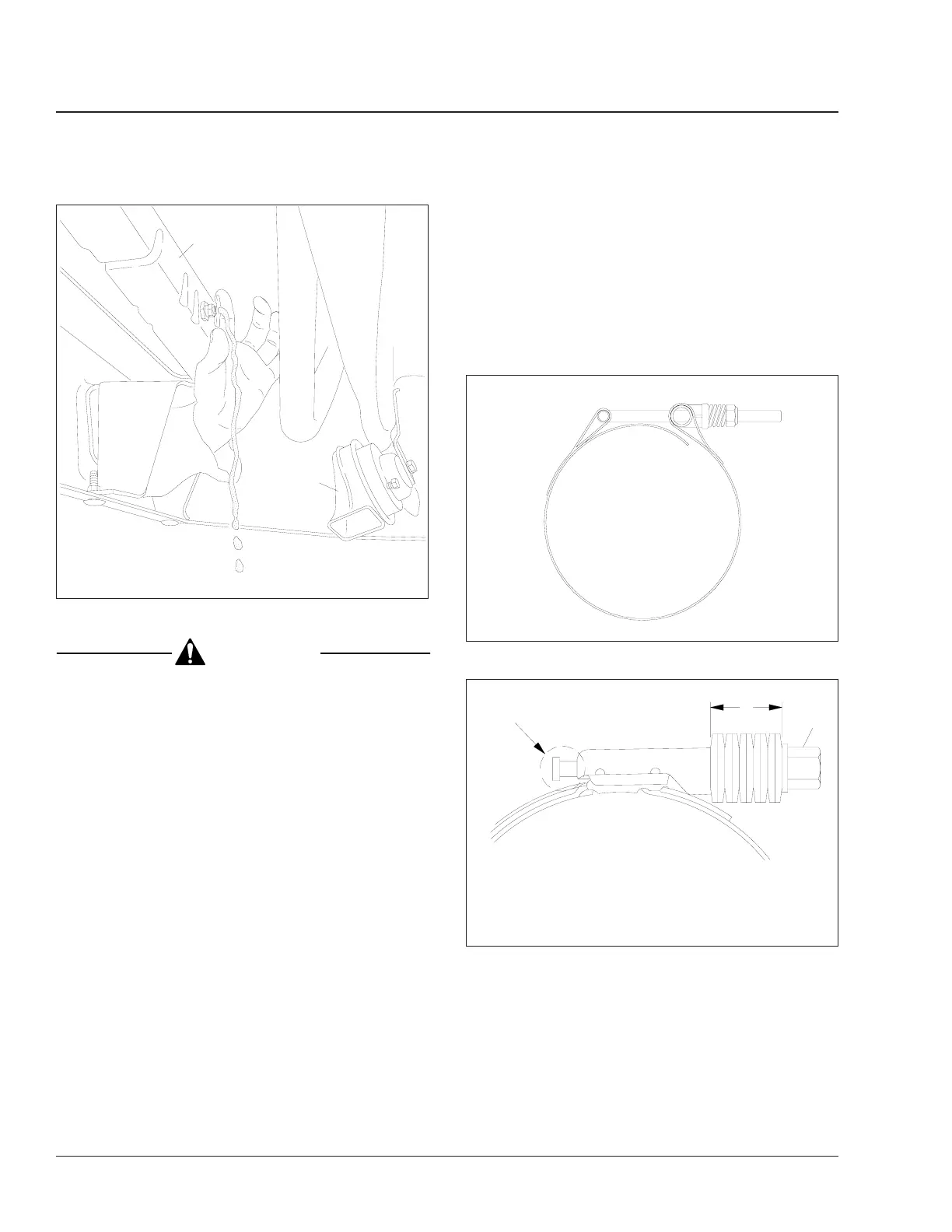

6. Connect the hoses. Your hose clamps can be

either T-bolt clamps (Fig. 3) or Breeze Constant-

Torque clamps (Fig. 4).

When working with T-bolt type hose clamps,

tighten the clamps 55 lbf·in (620 N·cm). These

clamps are now standard on hoses with an in-

side diameter greater than 2 inches (51 mm).

When installing the Breeze Constant-Torque

hose clamps, the clamps must be tightened to

the correct torque. The screw tip of the clamp

must extend about 1/4 inch (6 mm) from the

clamp housing, and the belleville washer stacks

must be collapsed almost flat. Use a torque

wrench to install these hose clamps correctly.

The correct installation torque for Breeze

Constant-Torque hose clamps is as follows:

For Breeze Constant-Torque hose clamps with a

5/16-inch tightening screw hex:

55 lbf·in (620

N·cm).

For Breeze Constant-Torque hose clamps with a

3/8-inch tightening screw hex:

90 lbf·in (1020

N·cm).

NOTE: All hose clamps will lose torque after

installation due to "compression set." However,

when correctly installed, Breeze Constant-

Torque clamps will hold enough torque to auto-

matically adjust and keep consistent sealing

pressure. During vehicle operation and shut-

f500108a

1

2

11/19/94

1. Radiator 2. Horn

Fig. 2, Draining The Engine Coolant

02/28/96

f200326

Fig. 3, T-Bolt Type Hose Clamp

08/15/94

f200286

A

B

1

A. The screw tip must extend about 1/4 inch (6 mm).

B. The belleville washer stacks must be collapsed

almost flat.

1. Tightening Screw Hex

Fig. 4, Breeze Constant-Torque Hose Clamp Installation

Engine Cooling/Radiator20

Business Class Trucks Maintenance Manual, August 200320/2

Loading...

Loading...