20–03 Fan Clutch Checking

(Noise Emission

Control)

Eaton Viscous Fan Clutch

CAUTION

If the fan drive assembly is damaged, replace the

unit as soon as possible. Operating a seized or

otherwise damaged clutch reduces fuel economy,

and could cause serious engine damage.

See Group 20 of the

Business Class

®

Trucks Ser-

vice Manual

for replacement instructions.

1. With the engine off, rotate the fan at least one

full turn by hand. It should have a smooth,

steady drag. If it does not, replace the fan clutch.

2. Check for physical damage to the fan or fan

shroud.

3. At the fan clutch mounting:

3.1 Check for correct drive belt alignment and

tension. For specifications, see Group 01

of the

Business Class

®

Trucks Service

Manual

3.2 Check for wear of the fan clutch bearings.

There should be no side-to-side or in-

and-out movement of the fan clutch.

3.3 Do all of the checks in Section 20.02 of

the

Business Class

®

Trucks Service

Manual

.

Horton Advantage

®

Fan Clutch

NOTE: If any part of the fan clutch needs to be

repaired or replaced, after performing the

checks below, see Group 20 of the

Business

Class

®

Trucks Service Manual

.

1. Disconnect the electrical cables from the battery.

Drain all air from the air system. If equipped with

an air starter, drain the air starter reservoir.

WARNING

If the engine starts during this procedure, the fan

could cause personal injury. If the vehicle is

equipped with an air starter, be sure that the air

starter reservoir is drained.

2. Inspect the electrical connections and wires to

the fan clutch solenoid. Secure the connection if

loose; replace wires and connectors if damaged.

3. Clean the fan clutch air solenoid valve filter, if

equipped.

3.1 Unscrew the fan clutch solenoid valve air

filter assembly and remove the filter ele-

ment.

3.2 Clean the filter element with cleaning sol-

vent.

3.3 Reassemble the clutch valve solenoid air

filter assembly and install on the vehicle.

4. Visually check the fan for bent, cracked, or dam-

aged blades. Replace if damaged. Check for ad-

equate clearance between the fan and other

components.

5. Check the fan belt for wear, tension, and align-

ment. Correct if necessary.

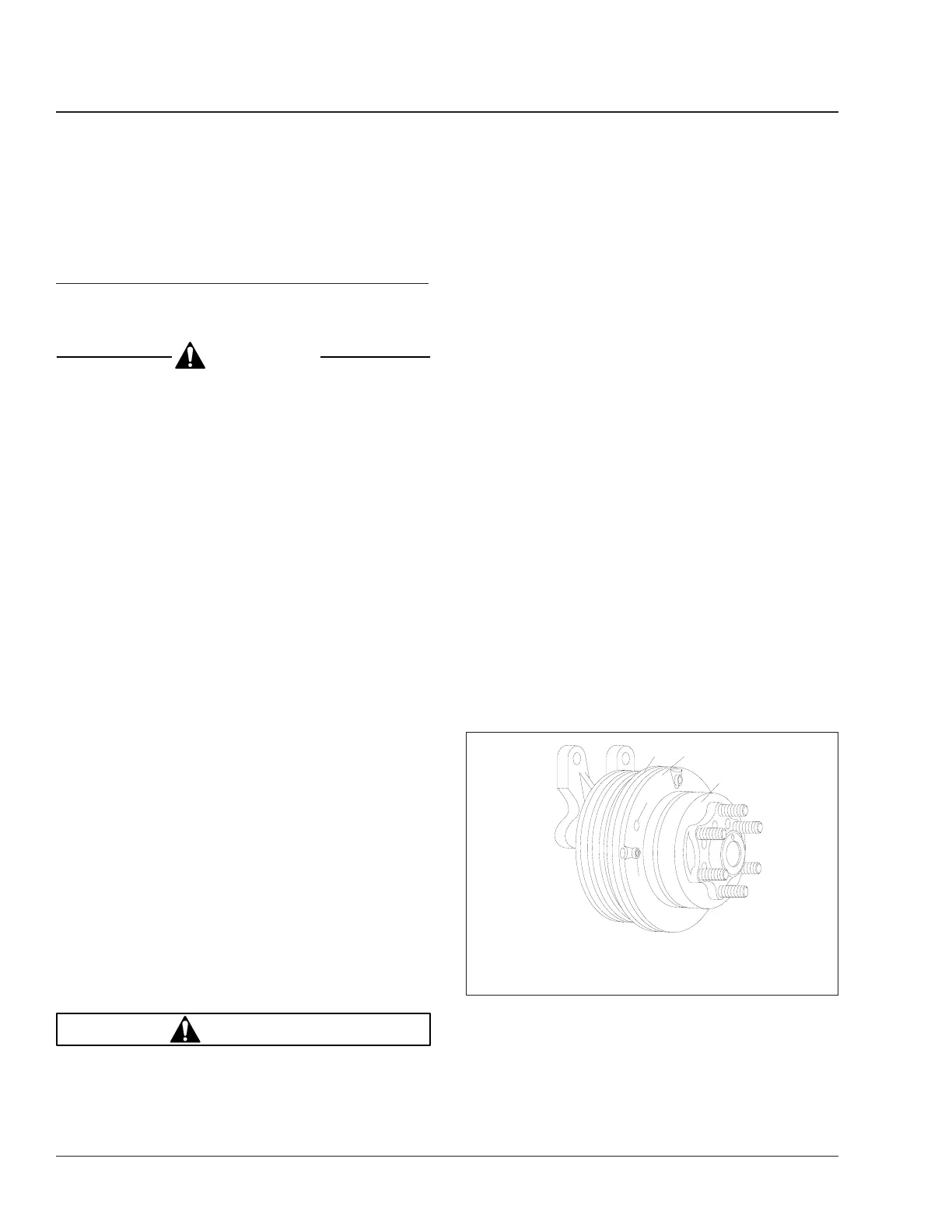

6. Check for wear on the friction facing. See Fig. 5.

Replace the friction facing if it is worn to a 1/16-

inch (1.6-mm) thickness or less. Also check the

facing for signs of oil contamination or burn

marks. If evidence of oil or burn marks are

found, replace the friction facing.

7. Connect the battery cables. Start the engine, and

charge the air system to 120 psi (827 kPa). Shut

f200290

1

2

08/08/94

3

4

5

1. System Sentry

®

Fuse

2. Safeguard Hole

3. Friction Facing

4. Piston Friction Disc

5. Air Chamber

Fig. 5, Horton Advantage Fan Clutch

Engine Cooling/Radiator20

Business Class Trucks Maintenance Manual, August 200320/4

Loading...

Loading...