Visually inspect the walking beam for cracks, or

other damage. If damage is found, see Group

32 of the

Business Class

®

Trucks Service

Manual

for replacement instructions.

Keep the vehicle supported by the jack stands

for the next operation.

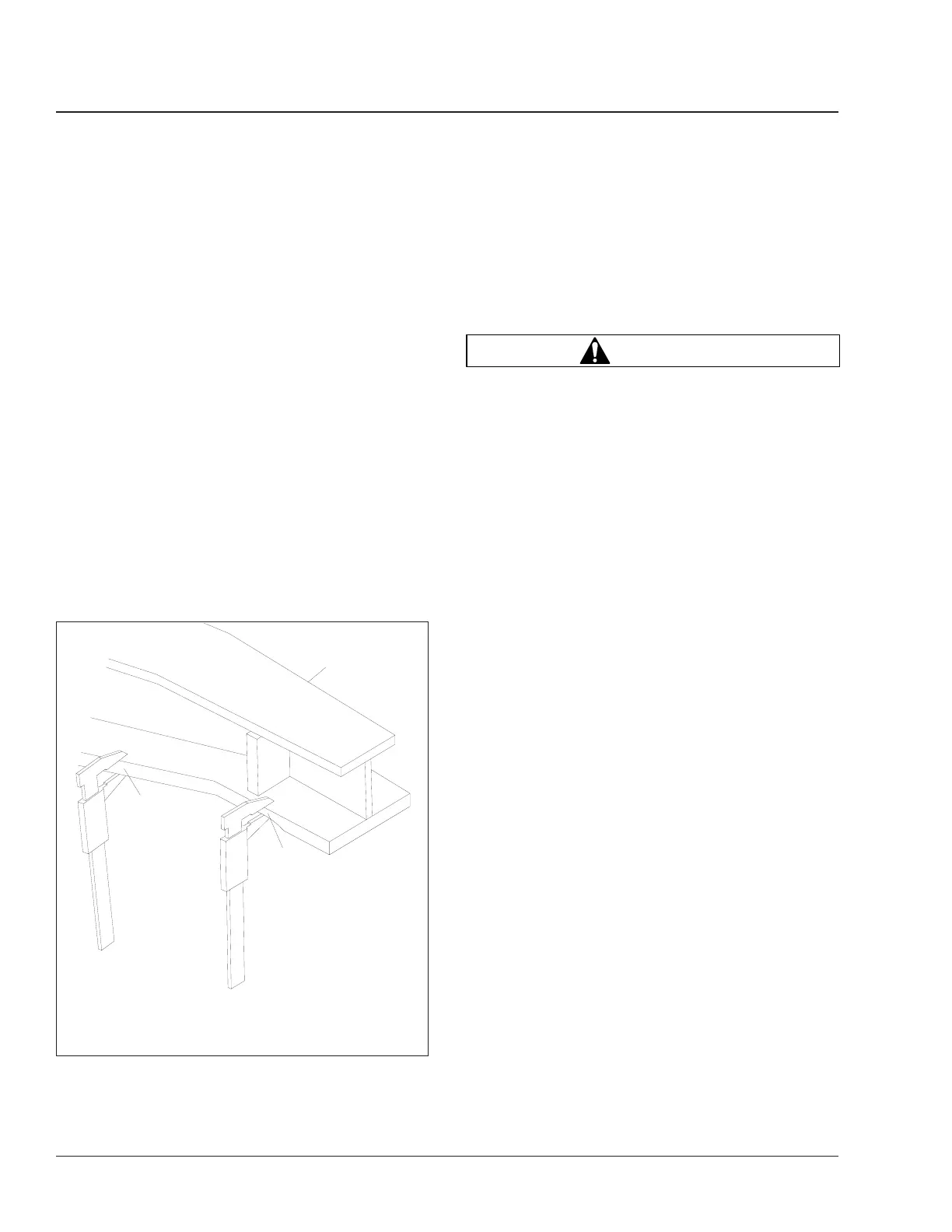

4. Manipulate the walking beam so that a microme-

ter, vernier, or dial caliper can be used to deter-

mine the wear area thickness on the bottom

face. See Fig. 8. Measurements should be taken

a minimum of 1/2 inch (13 mm) from the beam

flange edges to eliminate any edge wear that

may have occurred. Subtract the wear area

thickness (Fig. 8, Ref. B), from the non-wear

area (Fig. 8, Ref. A), to determine the amount of

wear.

If the beams show any wear greater than the

allowable 0.062-inch (1.5-mm) wear, a Chalmers

wear plate must be installed, or the walking

beam must be replaced. See Group 32 of the

Business Class

®

Trucks Service Manual

for re-

pair and replacement instructions.

5. Rotate the restrictor cans 360 degrees and visu-

ally inspect the cans for cracks, severe corro-

sion, and distortion. If any of these conditions are

present, or the restrictor can is missing, replace

the restrictor can. See Group 32 of the

Business

Class

®

Trucks Service Manual

for replacement

instructions.

WARNING

Replace all cracked or missing restrictor cans.

Failure to do so could lead to loss of vehicle con-

trol, which could result in property damage, seri-

ous personal injury or death. Vehicles with

cracked or missing restrictor cans may be driven

slowly to the nearest workshop for restrictor can

replacement.

6. Remove the jack stands, then lower the vehicle.

Check that the spring, or driveline brake is ap-

plied, then remove the wheel chocks.

Reyco 79KB Suspension Visual

Inspection

The Reyco 79KB suspension requires minimal main-

tenance. To provide trouble-free operation in over-

the-road applications, do the following visual inspec-

tion.

1. Park the vehicle on level ground. Apply the park-

ing brakes, and chock the tires.

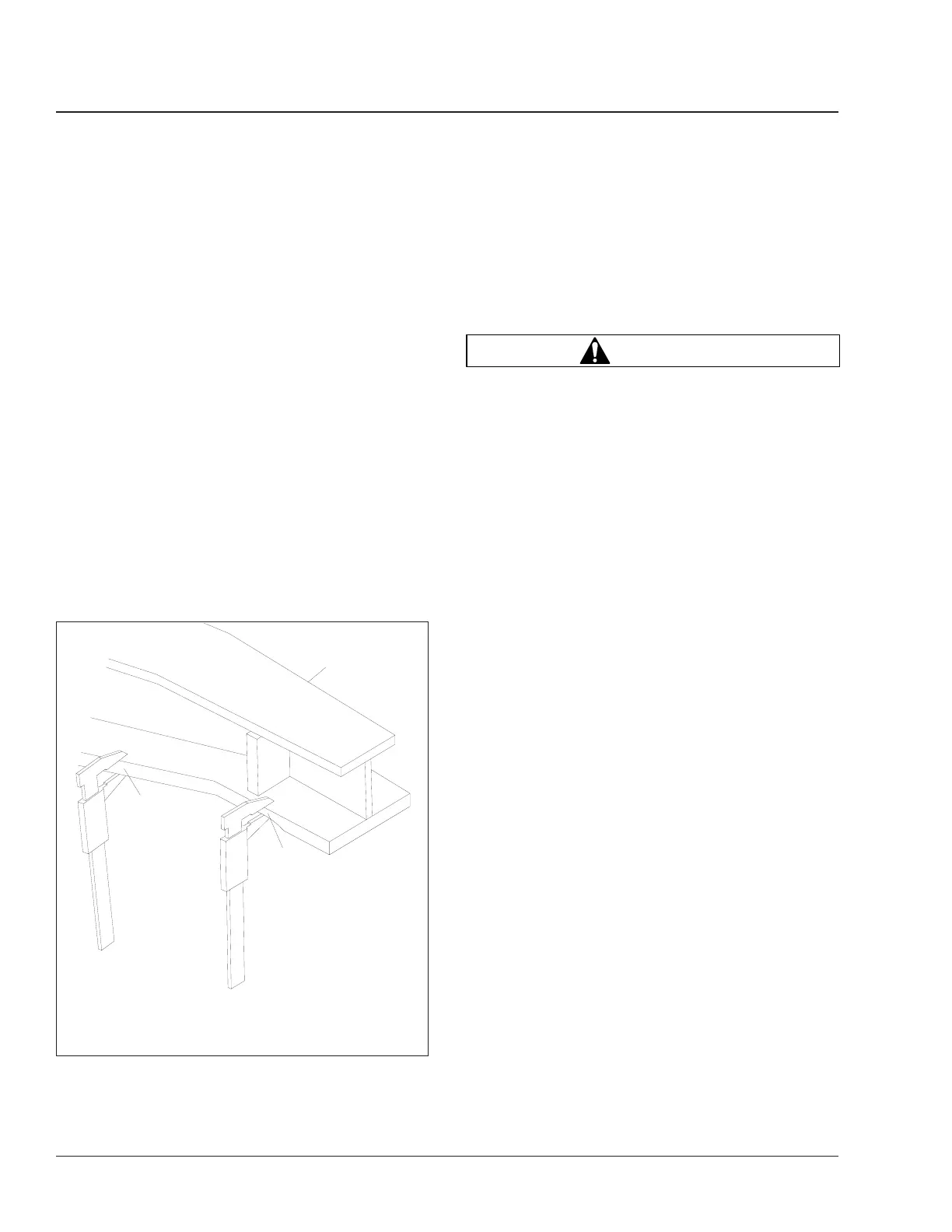

2. Check that the torque rod clamps are directed

away from the spring to prevent possible interfer-

ence during operation. See Fig. 9.

3. Check the fit of springs to hangers to ensure

good ride characteristics.

4. Check for elongated holes in the suspension

components. See Group 32 of the

Business

Class

®

Trucks Service Manual

for proper repair

procedures.

5. Check bushing condition. Replace any bushing

that is worn, cracked, dry-rotted, or otherwise

damaged. See Group 32 of the

Business Class

®

Trucks Service Manual

for removal and installa-

tion instructions.

6. Check tire condition. If abnormal tire wear is

found, check and replace all worn or damaged

components, and check suspension alignment.

See Group 32 of the

Business Class

®

Trucks

Service Manual

for component removal and in-

09/27/95

f320432

1

A

B

1. Walking Beam

A. Non-Wear Area

B. Wear Area

Fig. 8, Walking Beam End Wear Thickness

Suspension32

Business Class Trucks Maintenance Manual, July 199932/6

Loading...

Loading...