QUANTUM

™

LX EVAPORATOR CONTROL PANEL

MAINTENANCE

090.610-M (MAY 2016)

Page 20

POWER SUPPLY (Q5)

DESCRIPTION

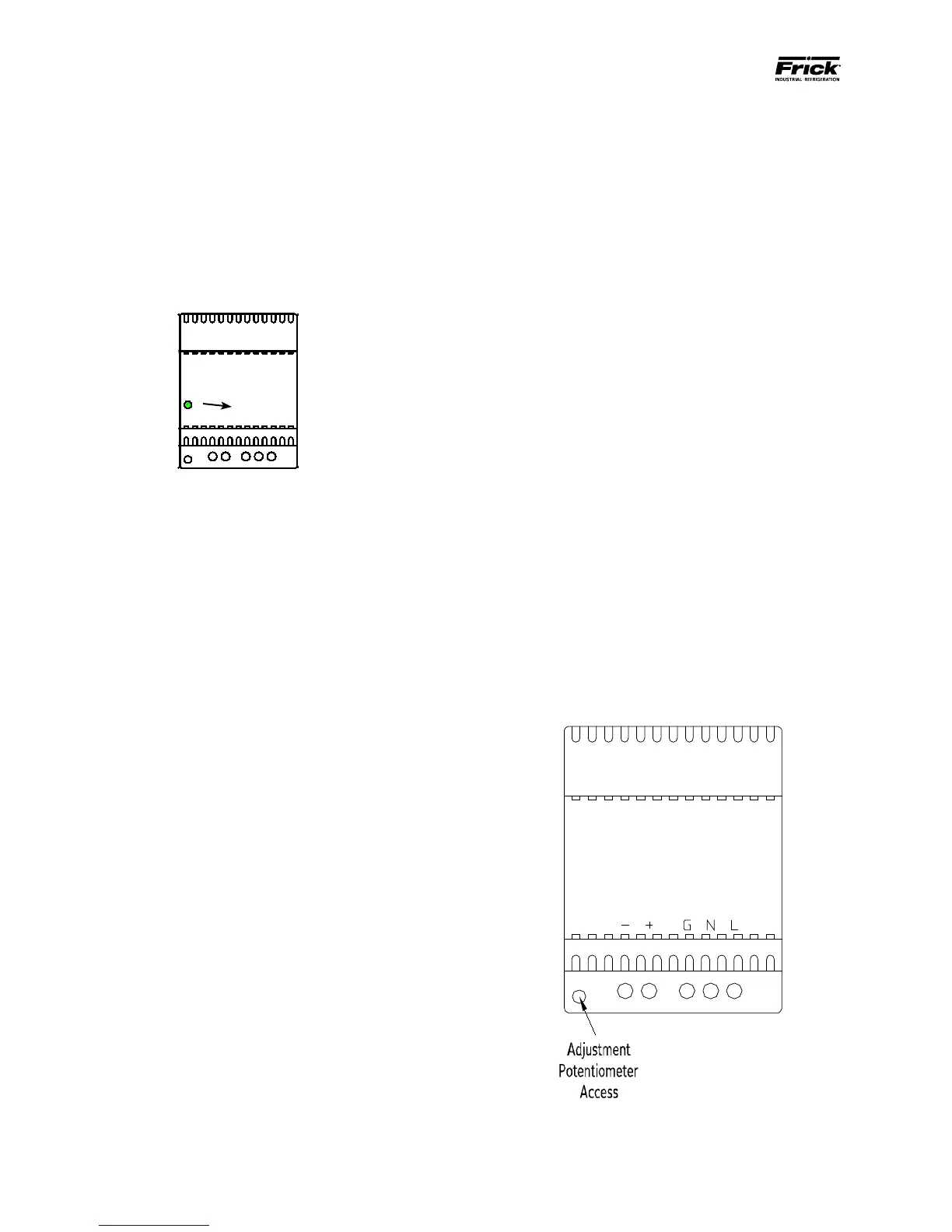

The power supply of the Q5 control panel consists a

single, 12 volt DC supply, and is located on the DIN rail

at the back of the enclosure.

The supply is adjustable and has an indicator to show

that it is powered. Refer to the following page for the

location for the adjustment.

12 Volt DCPower Supply

POWER DISTRIBUTION

12 Volt DC Power is distributed to the Q5 processor

board and Interface Board.

MEASURING VOLTAGES

CAUTION! Measuring and adjusting the power supply

voltage requires the control power switch to be ener-

gized. Extreme care must be observed when taking any

readings, as 120 or 230 VAC (depending on incoming

system voltage) will be present next to the DC volt-

age connector. Adjusting the supply requires the use

of a small Philips screwdriver inserted into the supply

to access an adjusting potentiometer. CAUTION: It is

possible for the screwdriver (and the person mak-

ing the adjustment) to come into contact with po-

tentially lethal voltages. Proper Personal Protective

Equipment (PPE) measures need to be observed.

All circuit boards within the Q5 control panel require

accurately adjusted DC voltages in order to function

properly. Periodic measurement and adjustment of the

DC power system is recommended for optimum sys-

tem operation. Over time, it is possible for tempera-

ture, humidity, vibration and component age, to de-

grade the accuracy of these voltages. When any of the

DC voltages begin to stray from their optimum range,

mysterious problems can begin to arise.

Even with a perfectly adjusted supply, it is possible for

a potential drop in voltage at each connection point.

This drop normally is in the millivolt range, but un-

der some conditions, the drop can be much greater (as

high as tenths of a volt). Some examples of problems

could be:

• Loss of or intermittent communications fail-

ures.

• Q5 reboots for no apparent reason.

Power ON

Indicator

• LED’s on the Q5 are lit, but nothing appears on

the display.

To perform measurements and adjustments on the

power supply voltage, use a reliable, calibrated Digi-

tal Volt Meter (DVM). The DVM should be accurate

to 1/100 of a volt DC. With the control power switch

turned ON, wait until the Operating Screen appears.

This is because the graphics required to create this

screen will draw more current than when the screen is

showing the normal POST (DOS) style messages during

a boot up. If the screen never appears however (possi-

bly due to a voltage problem), you will need to proceed

regardless of what is or is not displayed.

In order to properly measure the DC power system, it

must be checked at the DC power supply.

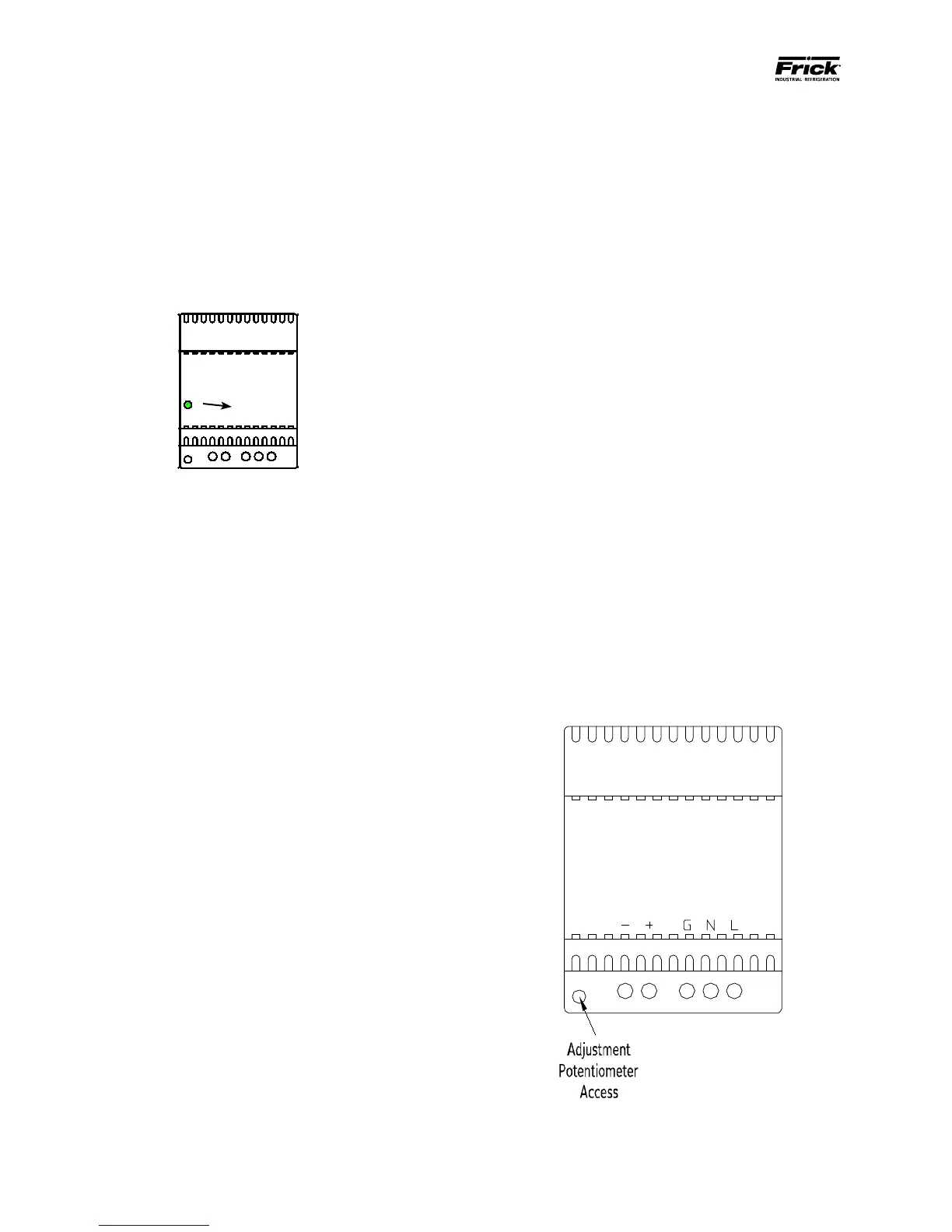

ADJUSTMENT

Ensure that the meter is set to the proper range (DC,

0-50 V or equivalent), as well as observing proper wire

polarity. The power supply drawing shown on the fol-

lowing page applies to all three power supplies. The

adjustment access hole for each supply is located on

the lower left of the front of the supplies. If an adjust-

ment is required, use a thin, Philips screwdriver, insert

the tip into the access hole for the appropriate voltage

potentiometer (refer to the diagram on the following

page for adjustment location). NOTE: Extreme care

must be used when adjusting the potentiometer.

Adjustment should only be performed by qualied

personnel. The use of a non-conductive device is

recommended.

+ -

DC

G N L

120 VAC

or

240 VAC

Loading...

Loading...