RXF PLUS MICROPROCESSOR CONTROL PANELS70-401 IOM

Page 16

through all menus, entering setpoints as required for the

system. Note that on initial power-up or simply on a loss of

setpoints the micro will display a NEW annunciation mes-

sage “FACTORY DEFAULTS SET”. If you need assistance

in optimizing setpoints, contact the FRICK Service Dept.

Since the lead lag version does not incorporate Auto-Cycle, it

is best to use standard programs on the compressors that the

RXF Plus controller sequences. This allows those compres-

sors to automatically switch to their respective Auto-Cycle

modes upon a 5 minute period of communications loss.

TROUBLESHOOTING

Most problems encountered with lead lag controls concern

two main areas:

1. Communications problems

2. Optimizing control sequencing

The RXF Plus lead lag control program has a new feature

that can be used to help diagnose communications prob-

lems. This feature may be accessed on a new display by

pressing the [F1] key, then pressing the [ * ] key once. This

new menu is actually the last menu in the program.

COM.IN:

## OUT:

The period after the word COM will blink for each character

received. While this may not be much help during normal

data exchanges, it will help the operator notice when the

micro is receiving abnormal single character hits. The ##

shows actual number of characters received since the last

pound # code was encountered, which will also reset this

counter to zero. Should the micro not receive a valid com-

mand sequence (most commands are less than 14 charac-

ters long) starting with a pound character, this counter will

count excessively high, up to 99 and stop, only resetting

upon receiving a pound code. The shaded area to the right

of IN: will show actual reception of data flow from right to

left. This information should be the normal data responses

from the compressors that the RXF Plus lead lag controller

is requesting data from. The shaded area to the right of OUT:

displays the actual command that the RXF Plus lead lag

controller is sending. This does not represent a feedback

loop verifying actual data sent; it only verifies what the mi-

cro is attempting to send.

The RXF Plus lead lag program has additional communica-

tions failure annunciation which will, on communication fail-

ure to a given compressor, report a message such as “COMP.

#1 COMM. FAIL”, with its associated time of failure. This

feature is enabled once a nonzero ID code is entered to add

a compressor to the lead lag sequence and lead lag is en-

abled. The controller must get 3 successive communica-

tions failures to actually set the failure, which also will turn

on the RXF Plus controllers alarm output. Individual (single

hit) communications errors will actually display “NOT COM-

MUNICATING” in the LEAD LAG STATUS display. This mes-

sage will disappear once normal communications have re-

sumed.

Optimizing control sequence is combining an educated

guess with trial and error. Every system is to some degree

unique, either due to operating conditions, equipment cali-

bration, or simply the operators desired control. The RXF

Plus lead lag program, on initial power-up, defaults all

setpoints to known values, such as all minimum slide valve

settings will default to 50 %. Start / Stop setpoints are actu-

ally defaulted to values that will prevent actual sequencing

from occurring. Hence the need for an operator to work

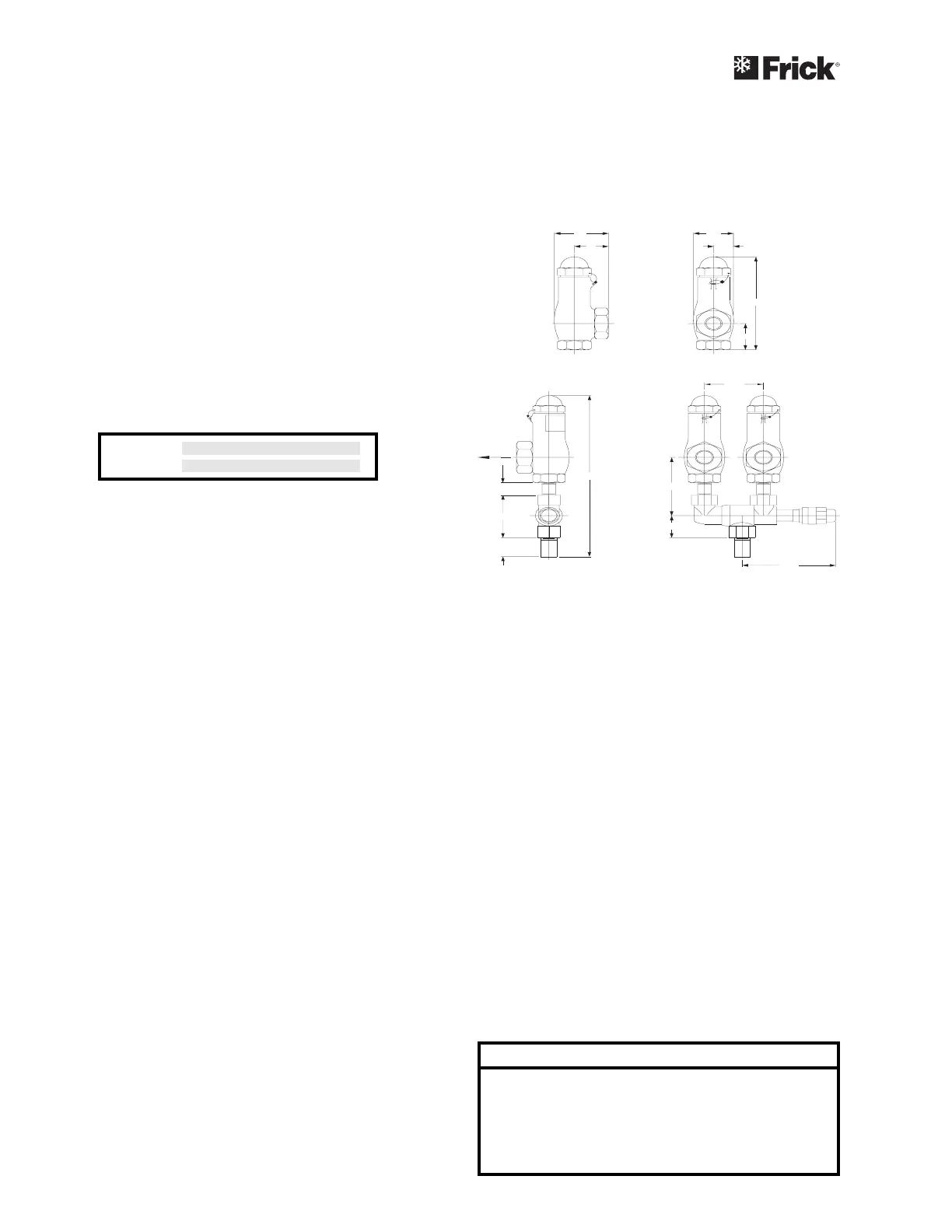

1 1/2" REF

13/4"

33/8"

1" REF

53/4"

3 5/8"

D

A

E

F

C

B

H

G

OUTLET

INLET

OUTLET

INLET

SRVSHNK1

MICROPROCESSOR

TELECOMMUNICATIONS

The Frick RXF Microprocessor comes with an onboard tele-

communications interface. The telecommunications feature

permits interfacing the microprocessor with a modem, re-

mote data communications terminal, or master computer via

RS-422 protocol. In the case of a modem, telephone lines

are used for the actual transmission of data permitting

communications from a remote location.

The components necessary to utilize the telecommunica-

tions feature will vary with the application. Information

concerning these items may be obtained from Frick Com-

pany, Waynesboro, Pa.

COMMUNICATIONS PROTOCOL

SPECIFICATIONS:

All commands must be in ASCII (CAPS) to be recognized. A

compressor with an ID code of [00] is considered disabled.

ID Codes from [01] thru [99] are valid and are recognized by

the microprocessor.

The following is a complete list of available command types:

COMMAND CODE and DESCRIPTION

I = Returns compressor status information.

R = Compressor start command.

S = Compressor stop command.

V = Compressor capacity control command.

P = Return Pressures information.

T = Return Temperatures information.

A = Return full load amps information.

C = Enter Change setpoints mode.

OPERATION

Loading...

Loading...