Page 3

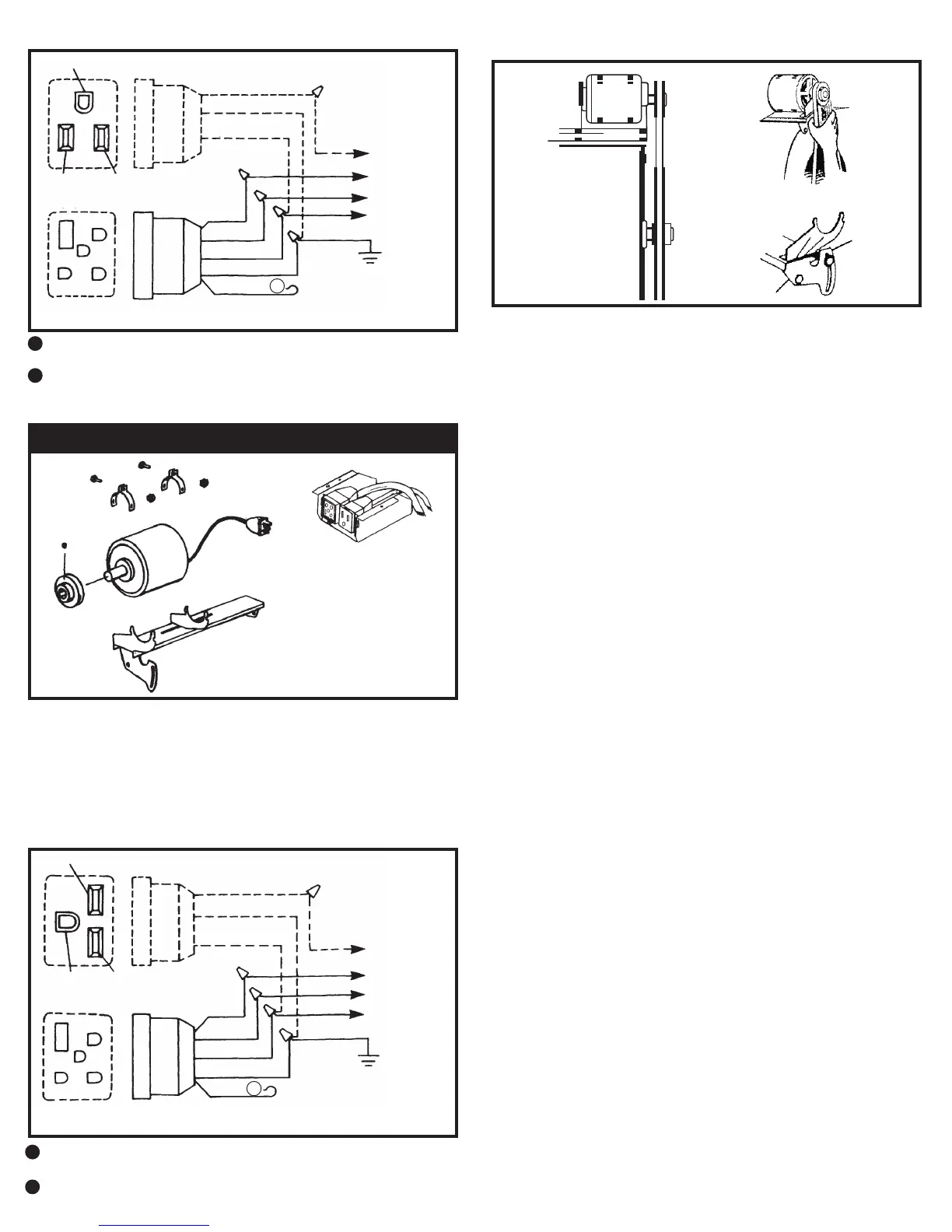

The orange wire is not used. Double it over and cover the bare end with

electrical tape.

A

INSTALLATION

1. Install the motor in the mounting cradle as shown.

2. Remove the junction box from the cooler.

3. Remove 120 volt pump and pump receptacle furnished with cooler and

replace it with the 240 volt LSP-94 pump and pump receptacle. (see

replacement parts list)

4. Wire the pump and motor receptacles per the schematic shown above.

5. Place both receptacles in the junction box as shown and re-attach the

junction box to the cooler top.

240 VOLT MOTOR KIT

The white wire is not used. Double it over and cover the bare end with

electrical tape or wirenut.

A

A

B

Green

Black

White

15A 120V

5 Pin

Motor

Recp.

Red

Black

White

Green

Orange

GND

Green

White

Black

Red

Pump

Black

Green

White

Lo

Hi

Com

Power

Supply

3 Pin

Green

Black White

15A 120V

Black

Green

White

3 Pin

Pump

Black

Red

White

Green

Lo

Hi

ComRed

Black

White

Green

Orange

5 Pin

A

Motor

Recp.

GND

A

Green

Black

Orange

15A 230V

5 Pin

Motor

Recp.

Red

Black

Orange

Green

White

GND

Green

Orange

Black

Red

Pump

Black

Green

Orange

Lo

Hi

Com

Power

Supply

3 Pin

B

Green

Black Orange

15A 230V

Black

Green

Orange

3 Pin

Pump

Black

Red

Orange

Green

Lo

Hi

Com

Red

Black

Orange

Green

White

5 Pin

A

Motor

Recp.

GND

Power

Supply

Power

Supply

120 VOLT MOTOR KIT

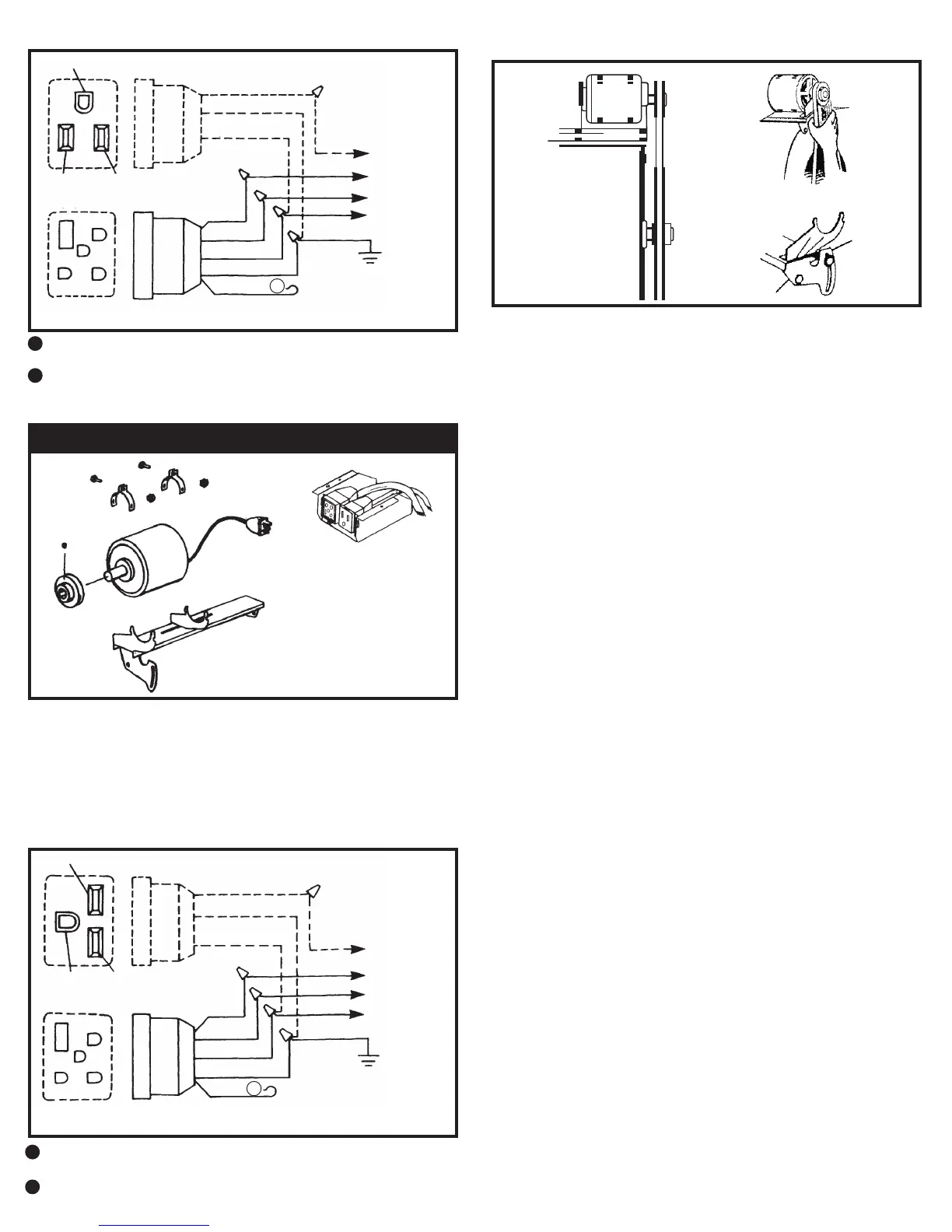

BLOWER BELT ADJUSTMENT

Correct belt tension adjustment is important. Incorrect adjustment increases

power consumption and shortens belt and motor life.

Install belt over motor and blower pulleys.

(A) check belt tension by squeezing (deecting) belt. Proper tension will allow

deection of 1/2 to 3/4 inch.

(B) To increase or decrease belt tension, loosen bolt in slot of motor support

brcket. Adjust belt to desired tension and re-tighten bolt.

OPERATION

PRE-WET PADS

For maximum cooling efciency, prior to the initial start up of the cooler

remove the pad frame assemblies from the cooler and spray the pad and

frames thoroughly with water from a garden hose.

Put the pad frame assemblies back on the cooler and while the pads are still

wet start the cooler with the pump on.

BUILT-IN WINTER CLOSURE (Down discharge units only)

An exclusive feature of your cooler (models in the 4800 to 6800 CFM range)

which is provided is the full closure damper. Your cooler is shipped from the

factory with the damper temporarily fastened to the side of the blower with a

shipping screw. Remove the screw and store the damper for later use during

winter months.

1. For Winter use of a damper, slide damper into cooler below the blower.age.

2. When starting the cooler in the Spring, remove the damper and store in a

safe place.

B

The red wire is not used on single speed motors. Double it over and cover

the bare end with electrical tape.

B

The red wire is not used on single speed motors. Double it over and cover

the bare end with electrical tape or wirenut.

Loading...

Loading...