Page 4

CLEANING

1. Remove pad frames and set them aside.

2. Remove the overow standpipe from the drain bushing and allow the

reservoir to empty.

3. Clean the internal surfaces of the cooler with a cloth and clean water. DO

NOT USE WIRE BRUSHES OR OTHER MEANS THAT MIGHT SCRATCH

THE PAINT. DO NOT USE ANY CHEMICALS OTHER THATN SOAP OR

DETERGENT TO CLEAN THE COOLER.

4. Rinse the cooler bottom pan throughly.

5. Clean the pump screen and remove any foreign material in the hose

adapter between the pump and hose. Remove any foreign material in the

distributor adapter located between the top end of the hose and the water

distributor.

6. Touch up and scratches or bare spots inside the cooler with a suitable

cooler coating.

OILING

Fill the oil cups on the blower shaft bearings with SAE#30 non-detergent

motor oil.

BELT ADJUSTMENT

Check belt tension. Re-adjust, if loose, per instructions in the Operation

section of this manual.

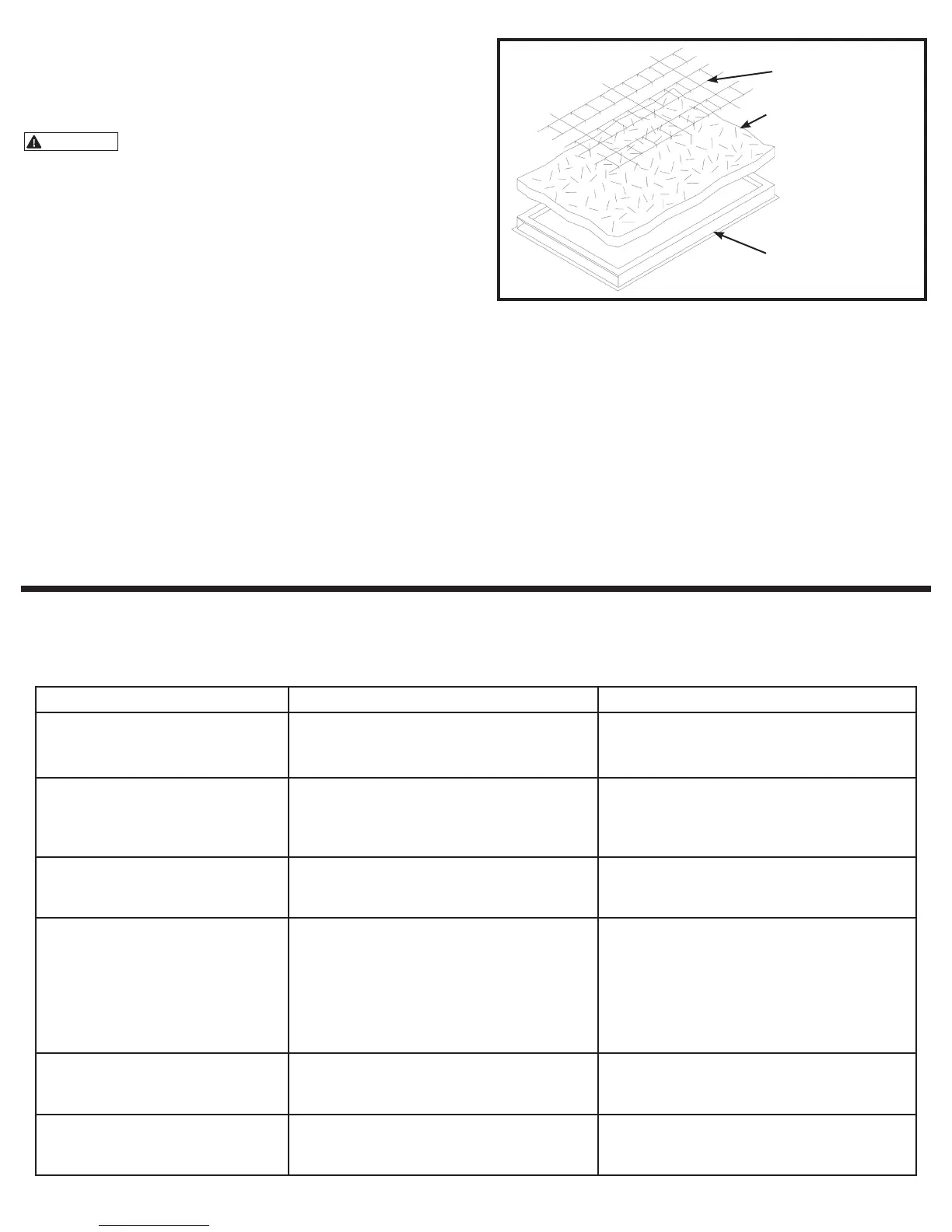

WIRE PAD RETAINER

ASPEN PAD

PAD FRAME

PAD REPLACEMENT

1. Lay pad frame on smooth surface with wire pad retainers up. Remove wire

retainers.

2. Remove and discard used pads.

3. Clean pad frames. Do NOT use wire brush or harsh chemicals that might

harm the paint nish. Touch up scratches and bare spots with touch up

paint.

4. Check slots in trough at top of pad frame to be sure they are open.

5. Replace pads with new media pads of the correct size.

6. Reinstall wire retainers.

7. Thoroughly wet pads with garden hose before re-installing.

MAINTENANCE

The cooler should be serviced at least once a year and more often if required.

This includes cleaning, oiling, belt adjustment or replacement (if required) and

pad replacement.

WARNING: ALWAYS DISCONNECT ELECTRICAL

POWER TO THE COOLER BEFORE WORKING ON

COOLER.

TROUBLESHOOTING:

The following guide is intended to help you diagnose and x some of the most commonly encountered problems; by no means does

this guide cover all of the possible problems you may encounter. If you cannot diagnose and correct the problem, or if it persists,

contact qualied service personnel. All electrical work should be done by, or with the help of, a qualied electrician.

PROBLEMS / SYMPTOMS POSSIBLE CAUSE CORRECTIVE ACTION

Water overow

1. Float valve out of adjustment

2. Float movement obstructed

3. Float valve defective

1. Adjust oat to 2½" water depth.

2. Free oat from obstruction

3. Replace oat assembly

Blower will not operate

1. Electrical power disconnected

2. Motor defective

3. Switch or thermostat defective

4. Blower belt broken

1. Check power receptacle and cord

2. Replace motor

3. Replace switch or thermostat

4. Replace belt

Fuse blown or circuit breaker

tripped

1. Wiring faulty or wired incorrectly

2. Motor faulty

3. Water pump faulty

1. Repair or replace defective wiring

2. Replace motor

3. Replace water pump

Dry pads

1. Water level incorrect

2. Pump intake clogged

3. Water pump faulty

4. Clogged water line

5. Trough clogged

6. Switch faulty

7. Wiring faulty

1. Adjust oat to 2-1/2" water depth

2. Remove obstruction

3. Replace water pump

4. Locate and free obstruction

5. Clear debris from trough

6. Replace switch

7. Repair or replace defective wiring

Noisy operation

1. Blower rubbing on housing

2. Motor sheave loose

3. Blower set screws loose

1. Reposition wheel

2. Tighten screws

3. Tighten set screws

Inadequate air ow

1. Pad plugged

2. Belt loose

3. Insufcient exhaust vent area

1. Replace pads

2. Adjust belt tension

3. Open windows or doors

Loading...

Loading...