En-5

• Do not install directly on the ground, this may result in equipment failure.

• The drain water is discharged from the bottom of the equipment. Construct a drain ditch

around the base and discharge the drain water properly.

• Provide ample space for ice buildup from condensate between the bottom of the unit and

the flat surface on which it is mounted. Otherwise, there is risk that the drainage water

will freeze between the device and the surface, disabling drainage.

Base

CAUTION

If the unit is installed in a region that is exposed to

high winds, freezing conditions, freezing rain, snow

fall or heavy snow accumulation, take appropriate

measures to protect it from those elements.

To ensure stable operation, the outdoor unit must be

installed on a raised stand or rack, at or above the

anticipated snow depth for the region.

The installation of snow hoods and drift prevention

fencing is recommended when blowing and drifting

snow is common to the region.

4. PIPE SELECTION

4.1. Selecting the pipe material

CAUTION

Do not use existing pipes.

Use pipes that have clean external and internal sides without any contamination which

may cause trouble during use, such as sulfur, oxide, dust, cutting waste, oil, or water.

It is necessary to use seamless copper pipes.

Material: Phosphor deoxidized seamless copper pipes.

It is desirable that the amount of residual oil is less than 40 mg/10 m.

Do not use copper pipes that have a collapsed, deformed, or discolored portion

(especially on the interior surface).

Otherwise, the expansion valve or capillary tube may become blocked with contaminants.

Improper pipe selection will degrade performance. As an air conditioner using R410A

incurs pressure higher than when using conventional refrigerant, it is necessary to

choose adequate materials.

• Thicknesses of copper pipes used with R410A are as shown in the table.

• Never use copper pipes thinner than those indicated in the table even if they are

available on the market.

Table. A (Wall thickness and pipe material for each diameter)

Outside

Diameter

mm

6.35 9.52 12.70 15.88 19.05 22.22 28.58

Wall Thick-

ness *3

mm

0.8 0.8 0.8 1.0 1.2 1.0 1.0

Material

COPPER *1

JIS H3300 C1220T-O or equivalent

COPPER *2

JIS H3300 C1220T-H or equivalent

Please select the pipe size in accordance with local rules.

*1: Allowable tensile stress ≥ 33 (N/mm

2

)

*2: Allowable tensile stress ≥ 61 (N/mm

2

)

*3: Endurance pressure of the pipes 4.2MPa

4.2. Protection of pipes

• Protect the pipes to prevent the entry of moisture and dust.

• Especially, pay attention when passing the pipes through a hole or connecting the

end of a pipe to the outdoor unit.

Location Working period Protection method

Outdoor

1 month or more Pinch pipes

Less than 1 month Pinch or tape pipes

Indoor - Pinch or tape pipes

4.3. Refrigerant pipe size and allowable piping length

CAUTION

Keep the piping length between the indoor unit and outdoor unit within the allowable

tolerance.

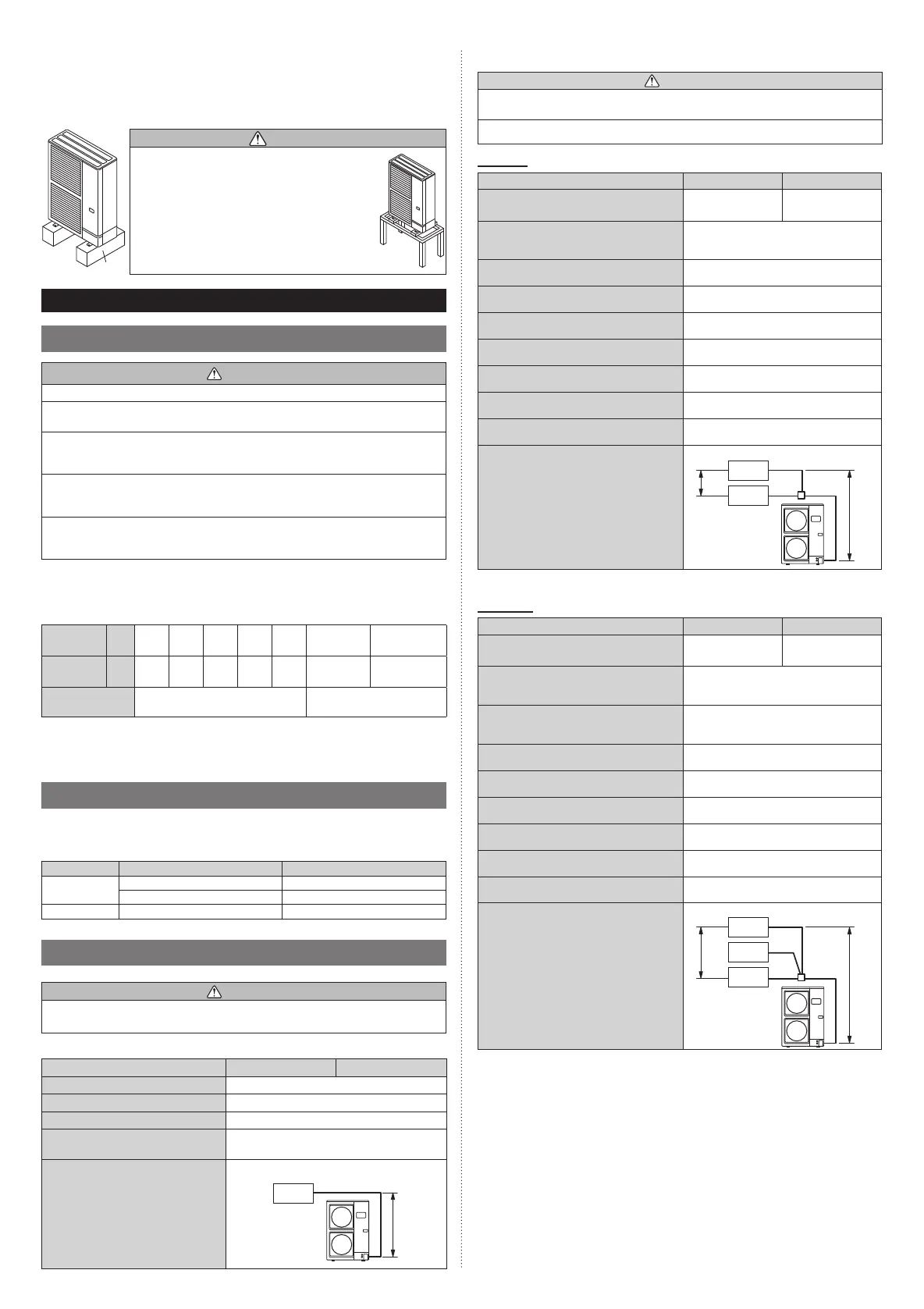

4.3.1. Single type installation

Capacity [BTU/h class] 72,000 90,000

Pipe diameter <Liquid/Gas> [mm (in.)] 12.70 (1/2) / 25.40 (1)

Max. piping length (L) [m] 100

Min. piping length (L) [m] 5

Max. height difference (H)

<Indoor unit to outdoor unit> [m]

30

View (Example)

H

L

Indoor Unit

4.3.2. Simultaneous operation multi type installation

CAUTION

Be certain to install indoor units in the same room because the combinations are for

simultaneous operation.

The lengths after branching should be equal if possible.

Twin type

Capacity [Btu/h class] 72,000 90,000

Indoor unit capacity

[Btu/h class]

36,000

+ 36,000

45,000

+ 45,000

Main pipe diameter (L1)

<Liquid/Gas>

(Standard) [mm (in.)]

12.70 (1/2) / 25.40 (1)

Branch pipe diameter (L2, L3)

<Liquid/Gas> [mm (in.)]

9.52 (3/8) / 15.88 (5/8)

Max. piping length

(L1+L2+L3)

[m]

100

*1

Min. piping length

(L1+L2+L3)

[m]

5

Max. branch piping

length (L2, L3) [m]

20

Max. difference between branch lengths

(L2 to L3)

[m]

8

Max. height difference (H1)

<Indoor unit to outdoor unit>

[m]

30

Max. height difference (H2)

<Indoor unit to indoor unit>

[m]

0.5

View (Example)

L1L3

L2

H1

H2

Indoor Unit

*1: For the standard pipe diameter.

Triple type

Capacity [Btu/h class] 72,000 90,000

Indoor unit capacity

[Btu/h class]

24,000 + 24,000

+ 24,000

30,000 + 30,000

+ 30,000

Main pipe diameter (L1)

<Liquid/Gas>

(Standard) [mm (in.)]

12.70 (1/2) / 25.40 (1)

Branch pipe diameter

(L2, L3, L4)

<Liquid/Gas> [mm (in.)]

9.52 (3/8) / 15.88 (5/8)

Max. piping length

(L1+L2+L3+L4)

[m]

100

*1

Min. piping length

(L1+L2+L3+L4)

[m]

5

Max. branch piping length

(L2, L3, L4) [m]

20

Max. difference between piping lengths

(L2, L3, L4) [m]

8

Max. height difference (H1)

<Indoor unit to outdoor unit> [m]

30

Max. height difference (H2)

<Indoor unit to indoor unit> [m]

0.5

View (Example)

L2

L3

L4 L1

H1

H2

Indoor Unit

*1: For the standard pipe diameter.

9380545231_IM.indb 59380545231_IM.indb 5 7/14/2017 8:53:11 AM7/14/2017 8:53:11 AM

Loading...

Loading...