Do you have a question about the Fujitsu ASU18RLQ and is the answer not in the manual?

Controls compressor operation based on temperature differences and outdoor conditions.

Controls compressor operation based on temperature differences and outdoor conditions.

Controls compressor frequency based on detected room temperature variation.

Automatically switches modes based on temperature changes.

Details indoor fan speeds and operation modes.

Provides outdoor fan speeds and behavior based on compressor frequency and temperature.

Manages vertical louver position and swing operation for airflow direction.

Explains compressor operation frequency ranges and startup control.

Describes ON, OFF, program, and sleep timer functions.

Explains the coil-dry operation function and its duration.

Details the air clean operation function, which performs sterilization.

Specifies conditions for initiating defrost operation based on temperature.

Outlines the conditions for ending the defrost operation.

Defines the conditions for off defrost operation in heating mode.

Specifies the conditions for ending the off defrost operation.

Protects against high discharge gas temperature by adjusting compressor frequency.

Controls compressor frequency to prevent exceeding outdoor unit input current limits.

Prevents freezing by decreasing compressor frequency when indoor heat exchanger temperature is low.

Stops the compressor if outdoor heat exchange sensor temperature rises.

Controls compressor frequency based on indoor heat exchanger temperature during heating.

Lists necessary tools and equipment for R410A refrigerant installation and servicing.

Provides precautions for installing R410A refrigerant pipes and flare nuts.

Highlights differences in refrigerant oil and pressure for R410A compared to R22.

Explains the phase-out schedule of HCFC and the nature of HFC refrigerants.

Discusses differences in oil, compressor, and heat exchangers with R22.

Addresses the issue where the unit does not operate and indicator lamps are off.

Describes how the self-diagnosis function memorizes errors and how to read/erase memory.

Details error codes, their causes, and diagnosis methods for various issues.

Provides check points and procedures for serial signal receiving errors.

Provides diagnosis for refrigerant cycle issues and component checks.

Details jumper settings for remote control custom codes and auto restart functions.

Presents graphs of outdoor unit pressure, current, capacity, and input data.

Lists resistance values for various thermistors across temperature ranges.

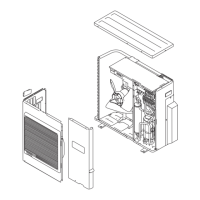

Shows exploded view diagrams of indoor and outdoor unit components for replacement.

Details the process of attaching the inverter assembly and connecting leads.

| Seasonal Energy Efficiency Ratio (SEER) | 16.0 |

|---|---|

| Coefficient of Performance (COP) | 3.5 |

| Cooling Capacity | 18000 BTU/h |

| Power Supply | 208-230V, 60Hz |

| Refrigerant | R410A |