ERROR

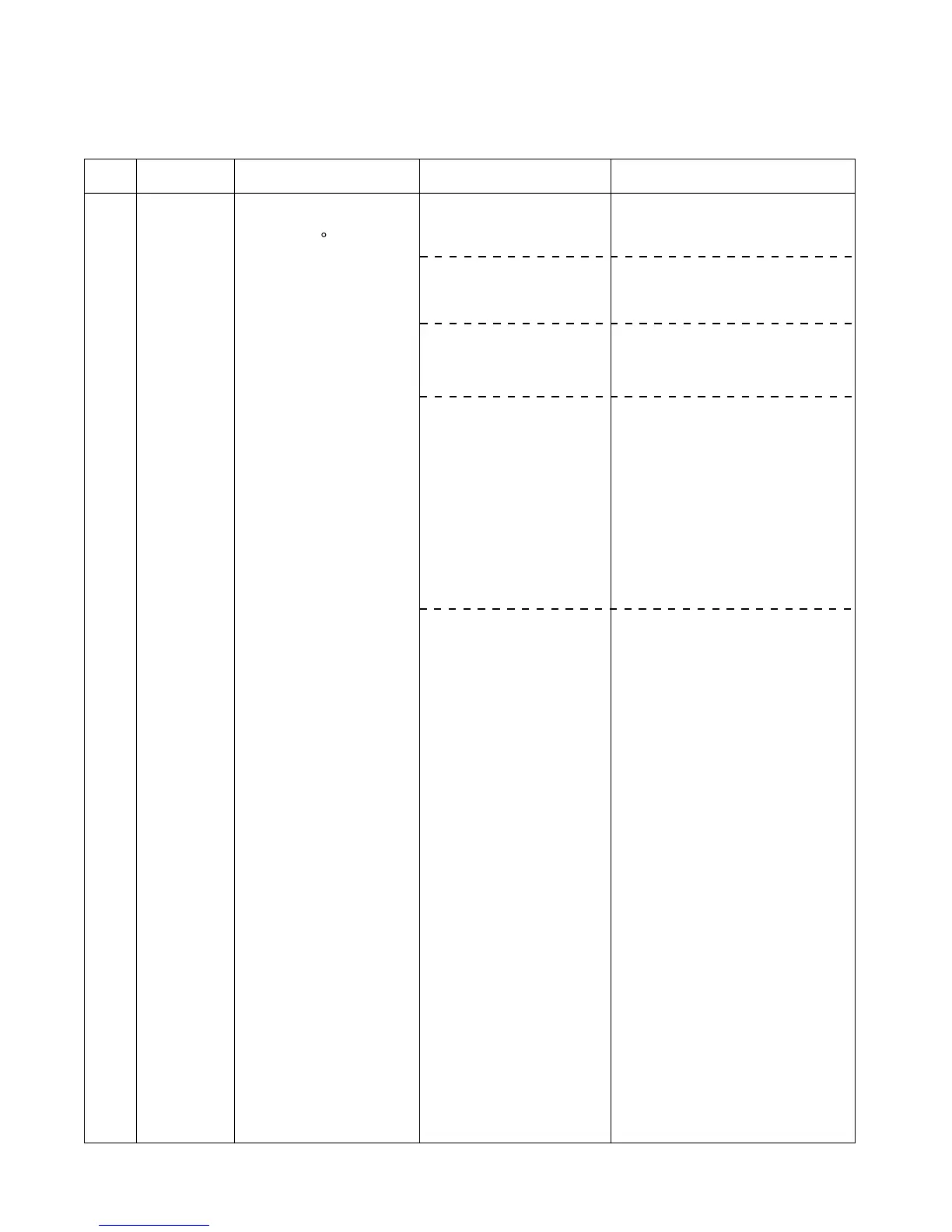

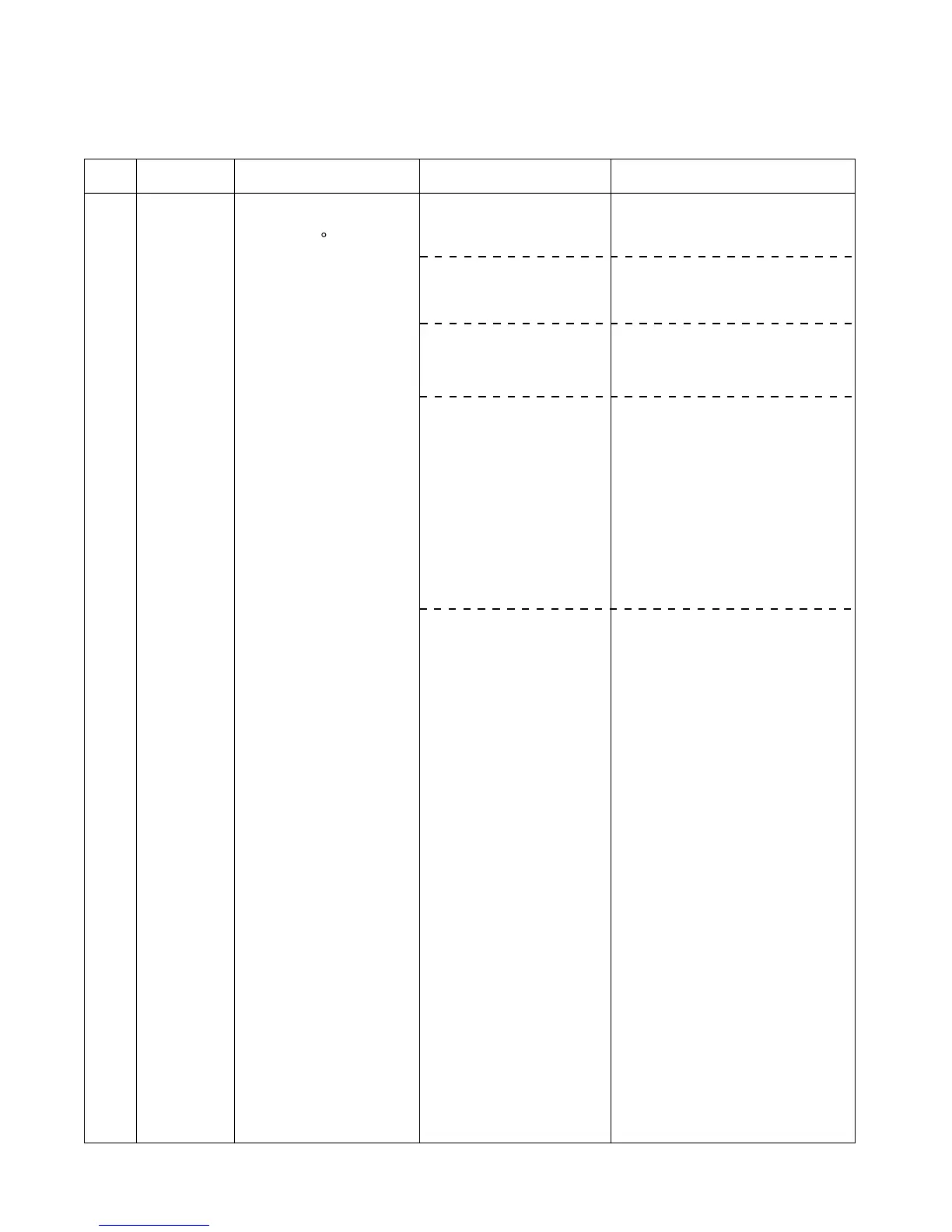

CONTENTS

ERROR CAUSE

COUNTERMEASURE

Discharge

temperature 1

error

1. Check the gas leak and additional

refrigerant amount, and recharge

suitable refrigerant.

1. Gas leak or lack of refrigerant.

1. Error occurrence condition

Discharge temperature 1

rises to 130 C or higher for

40 minutes and compressor

1 is stopped twice or more.

2. Relevant operation

Error is displayed on LED of

outdoor unit and output to

communication bus line.

3. Clearance

When all the following

conditions are satisfied:

1) Discharge temperature

protector 1 reset.

2) Discharge temperature

protector is not operated for

40 minutes or longer.

21

2. Check outdoor fan motor operation.

Remove the obstruction in wind path.

If fan motor is faulty, replace motor.

3. Check if the wiring of discharge

temperature sensor THD1 loosens or

comes off and check the resistance

THD1. If it's abnormal, replace sensor.

4. Check operation and coil resistance

of following electronic expansion

valve. If it's abnormal, replace

electronic expansion valve.

Coil resistance measurement points.

Red-white, red-orange, brown-yellow,

brown-blue.

(1) Outdoor unit electronic expansion

valve EEV1 and EEV2 Coil

resistance: 192 +/-19 ohms.

(2) Indoor units electronic expansion

valve EEV Coil resistance:

150 +/-50 ohms.

5. Check operation of following solenoid

valves. If operation is faulty, replace

solenoid valve.

Cooling operation.

(1) Outdoor unit solenoid valve SV1.

(2) RB unit solenoid valves SVB and

SVS.

Heating operation.

(3) Outdoor units solenoid valves SV1,

SV7, and SV8.

(4) RB unit solenoid valve SVD.

Heat recovery operation (1), (2),

(3), (4).

2. Outdoor fan motor is faulty.

3. Discharge temperature

sensor THD1 is faulty.

4. Electronic expansion valve

operation is faulty.

5. Solenoid valve operation is

faulty.

ERROR

CODE

05-22

Loading...

Loading...