Checking gas leakage and purging air6. 1. 1.

Gas leak checks are performed using either vacuum or nitrogen gas, so select the

proper one depending on the situation.

Checking gas leaks with vacuum:

Check if the piping connections are secure.(1)

Remove the cap of 3-way valve, and connect the gauge manifold charge hoses to (2)

the charging port of the 3-way valve.

Open the valve of the gauge manifold fully.(3)

Operate the vacuum pump and start pump down.(4)

Check that the compound pressure gauge reads -0.1 MPa (-14.7 psi), operate the (5)

vacuum pump for 30 minutes or more in each valve.

At the end of pump down, close the valve of the gauge manifold fully and stop the (6)

vacuum pump.

(It checks that leave as it is for about 10 minutes, and a needle does not return.)

Disconnect the charge hose from the 3-way valve charging port.(7)

Remove the blank caps, and fully open the spindles of the 2-way and 3-way (8)

valves with a hexagon wrench.

[torque: 6 to 7 N·m (53 to 62 lbf·in)].

Tighten the blank caps and charging port cap of the 2-way valve and 3-way valve (9)

to the specied torque.

Checking gas leaks with nitrogen gas:

Check if the piping connections are secure.(1)

Remove the cap of 3-way valve, and connect the gauge manifold charge hoses to (2)

the charging port of the 3-way valve.

Pressurize with nitrogen gas using the 3-way valve charging port.(3)

Do not pressurize up to the specied pressure all at once but do so gradually.(4)

1

Increase the pressure up to 0.5 MPa (73 psi), let it sit for about 5 minutes and

then check for any decrease in pressure.

2

Increase the pressure up to 1.5 MPa (218 psi), let it sit for about 5 minutes

and then check for any decrease in pressure.

3

Increase the pressure up to the specied pressure (the pressure designed for

the product) and then make a note of it.

Let it sit at the specied pressure and if there is no decrease in pressure then it is (5)

satisfactory. If a pressure decrease is conrmed, there is a leak, so it is necessary

to specify the leak location and make minor adjustments.

Discharge the nitrogen gas and starting removing the gas with a vacuum pump.(6)

Open the valve of the gauge manifold fully.(7)

Operate the vacuum pump and start pump down.(8)

Check that the compound pressure gauge reads -0.1 MPa (-14.7 psi), operate the (9)

vacuum pump for 30 minutes or more in each valve.

At the end of pump down, close the valve of the gauge manifold fully and stop the (10)

vacuum pump.

Disconnect the charge hose from the 3-way valve charging port.(11)

Outdoor unit5. 5.

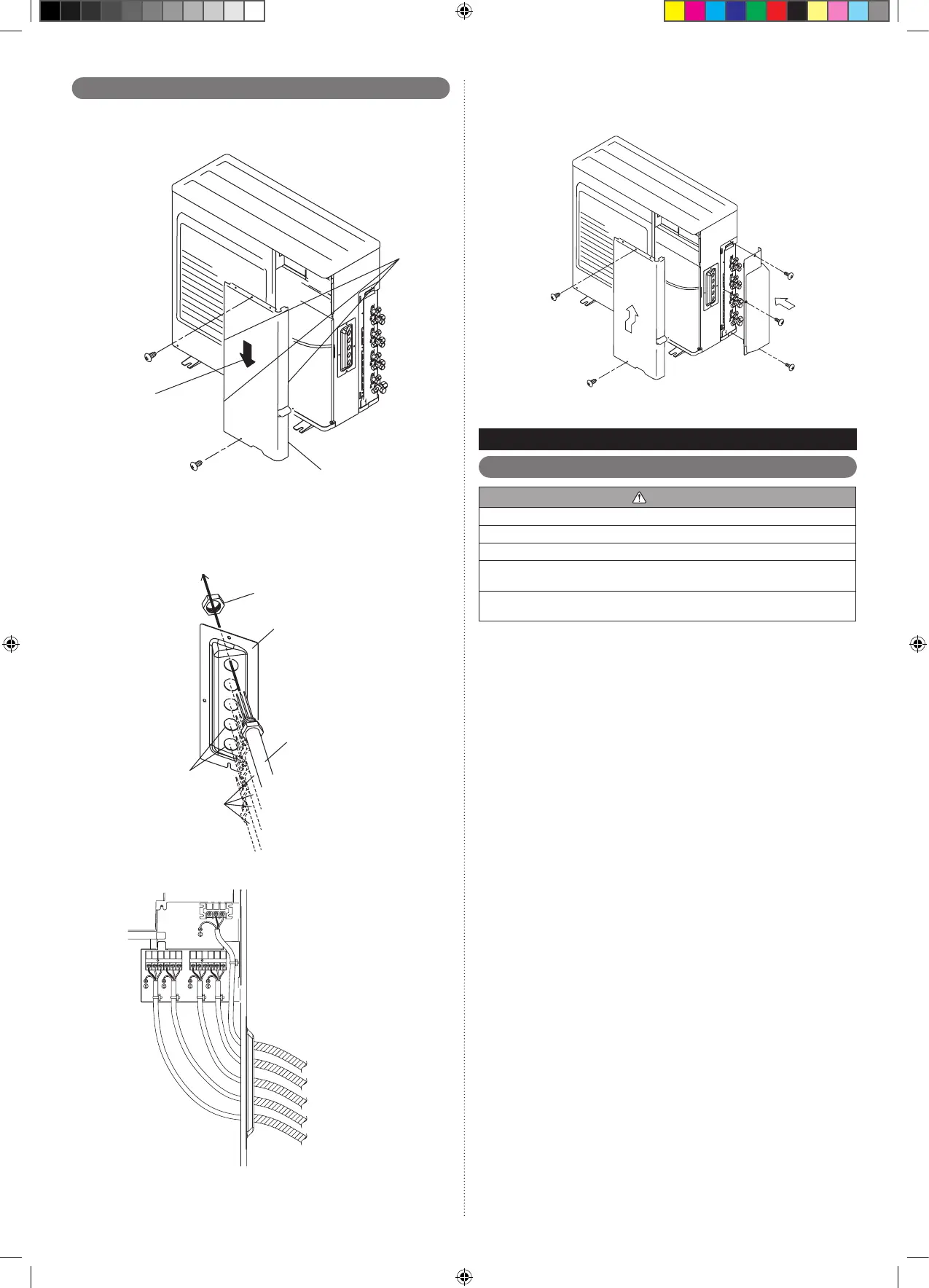

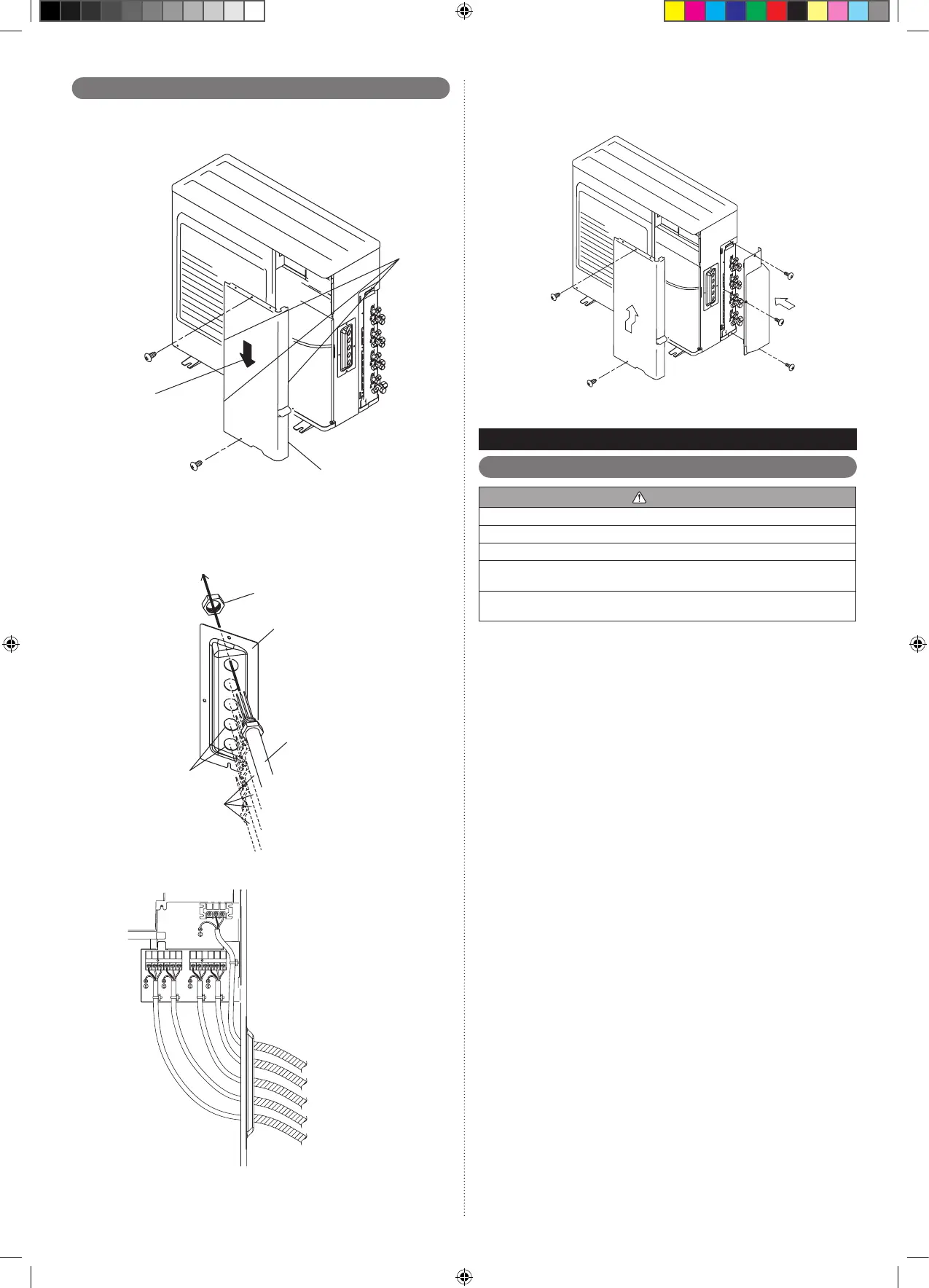

(1) Service cover removal

• Remove the two mounting screws.

• Remove the service cover by pushing downwards.

Loading...

Loading...