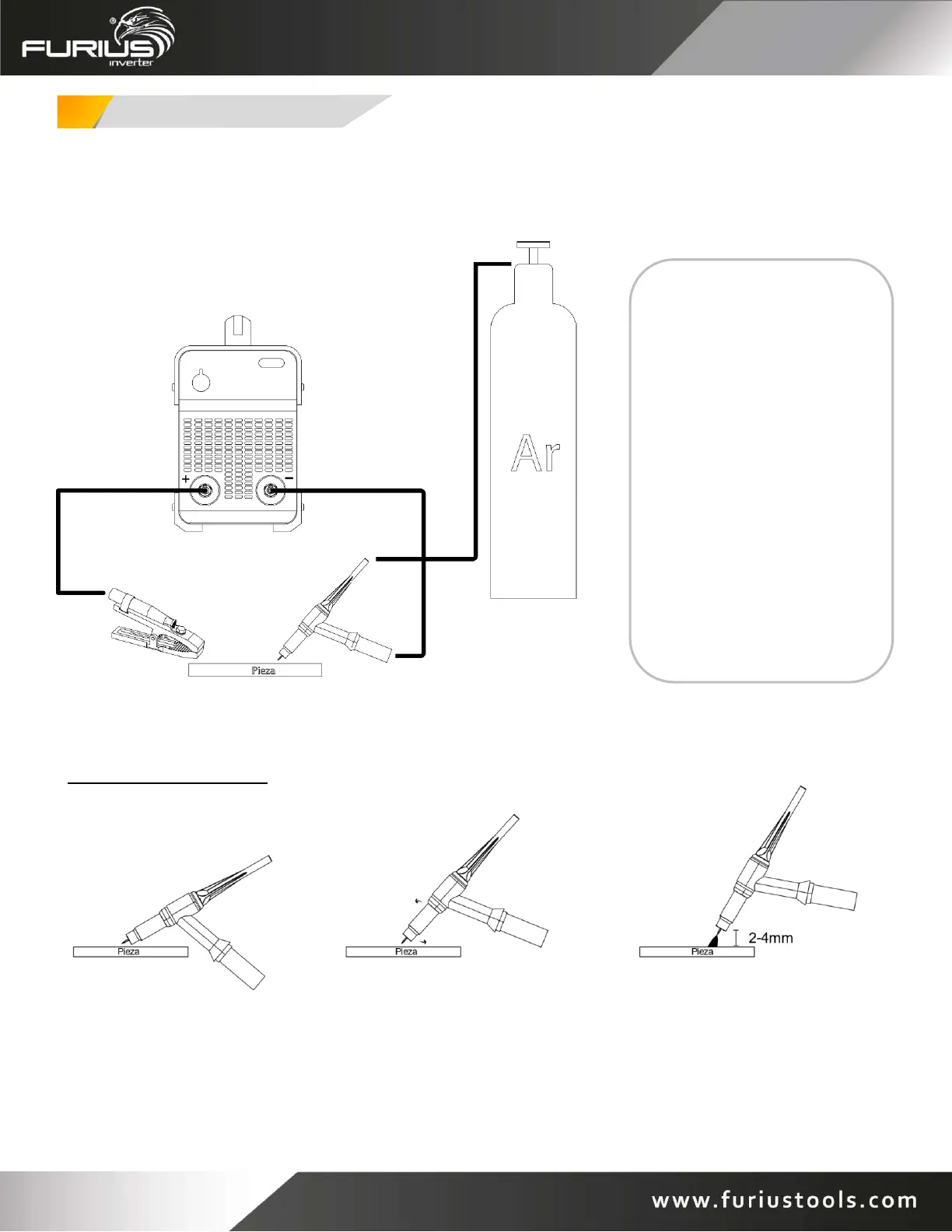

To use TIG with the Furius FIX 201 connect the torch to the negative socket or connector of the machine and the work

clamp (ground) to the positive socket or connector of the machine, as shown in the following figure:

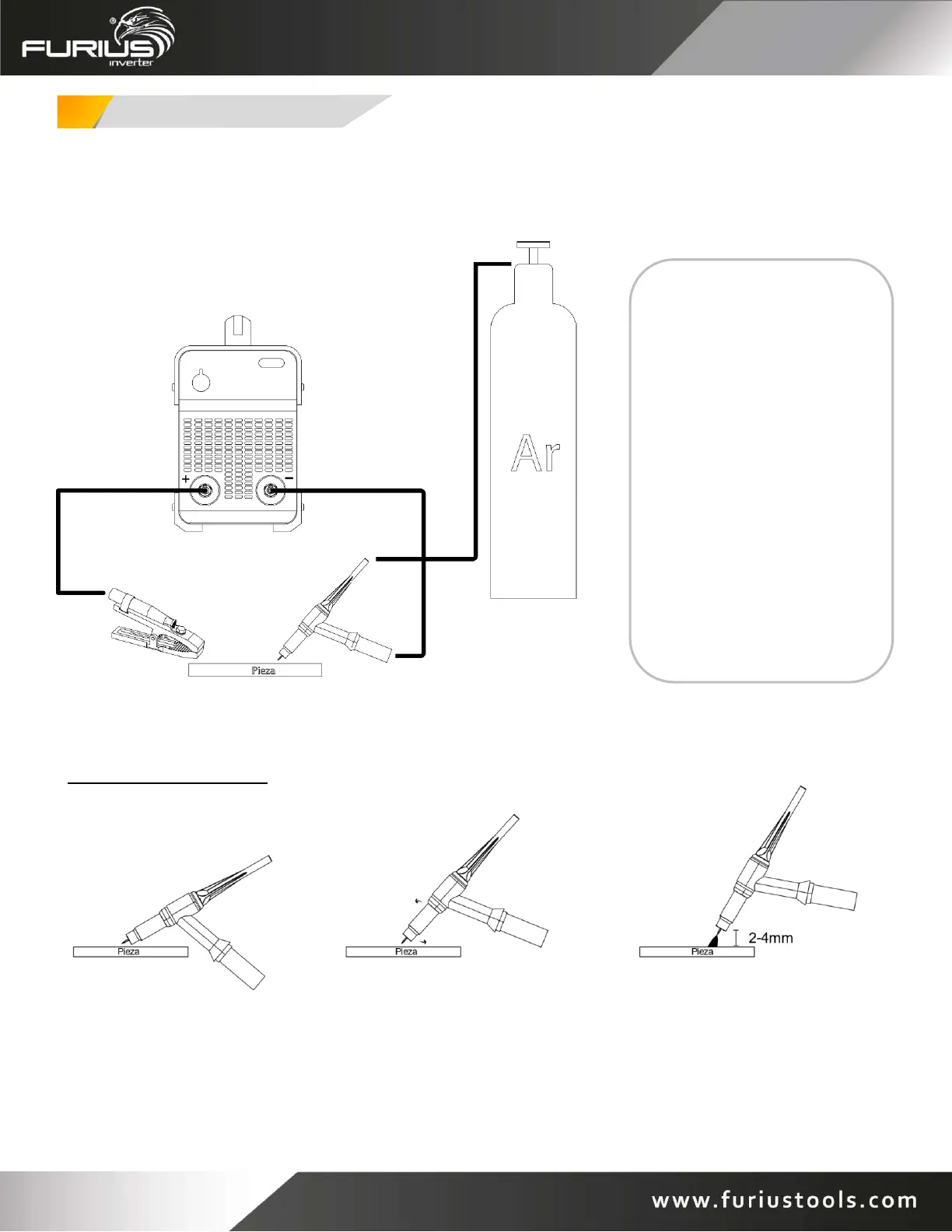

FROM 2 TO 4 MM TO START THE

1. PLACE THE TORCH IN POSITION

Argon gas from a cylinder with a

flow regulator must be used for

this gas. The torch must be

connected directly to the

regulator. The equipment does

not have a solenoid valve to

control the gas flow, so the use of

a torch with a knob is

recommended for regulation and

interruption of gas flow.

It is recommended to adjust a gas

flow of 10 to 20 l / m or 21 to 40

The arc start mode in TIG is scratch

TIG, which means that to start the

arc it is necessary to scratch the

tungsten against the workpiece.

Loading...

Loading...