ATTUATORI .

- PNEUMATIC ACTUATORS AND ACCESSORIES -

UsermanING ISSUE .10 March 2004

GT ATTUATORI S.r.l. REA MI 1558400 FAX (02) 90390368

V.le Europa 17 - 20090 Cusago Partita IVA e Cod.Fisc.12449540157 TEL (02) 90390322

Milan - ITALY- E-mail g.trevisan@iol.it

www.gtrevisan.it

PAG. 5 OF 20

INSTALLATION

OPERATION &

MAINTENANCE MANUAL

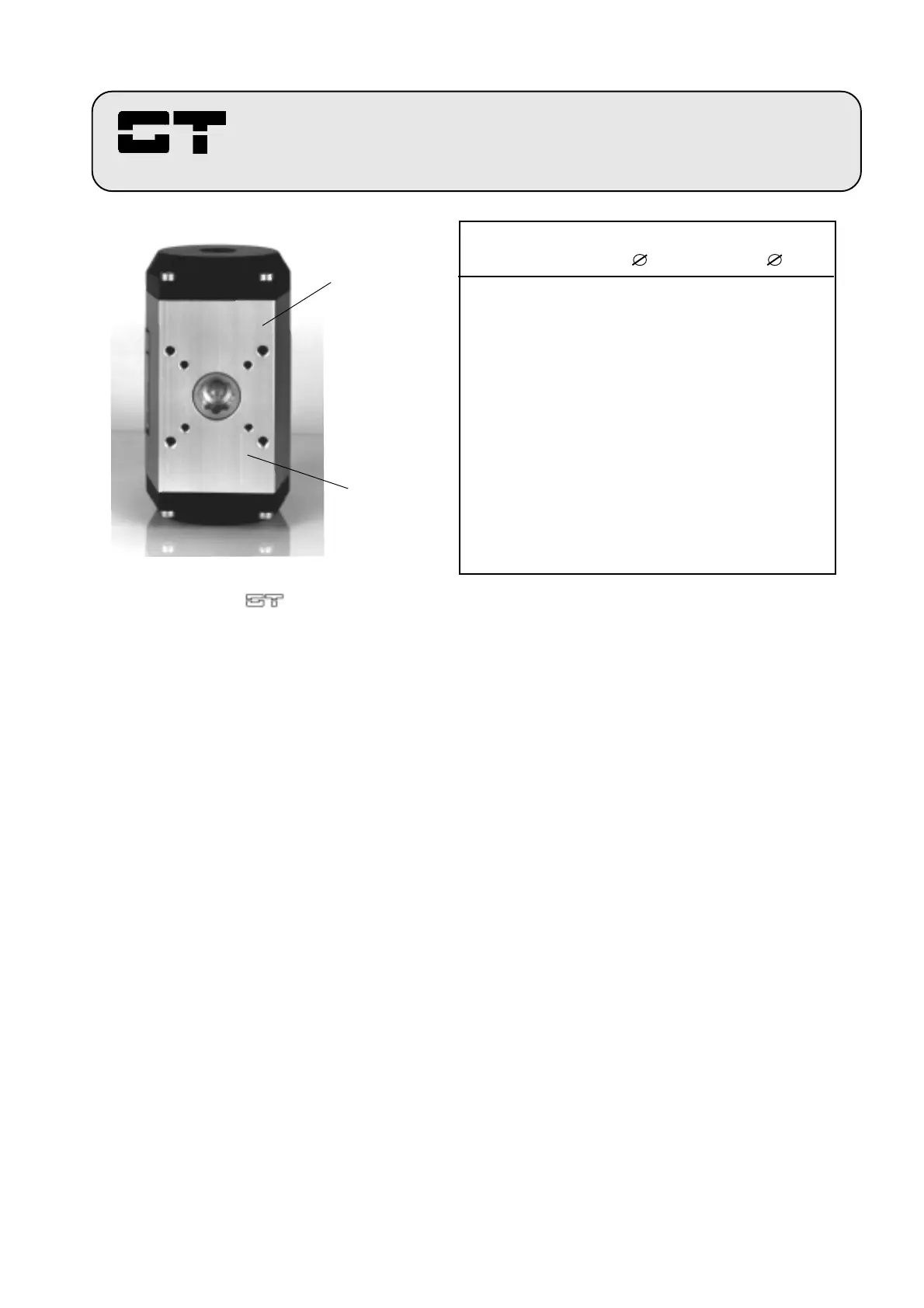

TABLE 1

ISO dimensions represents actuator

mounting bolt circles

FOR ACTUATORS INSTALLATION PLEASE FOLLOW THESE STEPS:

4.1 - Insert valve stem directly into actuator pinion, or through the coupling if necessary, to check for

proper fit.

NOTE.: If actuator is DOUBLE ACTING check to see if pinion is in the normal position, or rather in the

position necessary to get the valve closed.

4.2 - Make sure valve is in normal position before proceeding. Figure 3 describes the correct normal position

of all G.T. Componenti actuators (Including spring return types with FCW, assembling A and FCCW assembling C,

applications).

4.3 - Install mounting bracket on to valve and hand tighten all fasteners. Be sure not to fully torque bolts until

entire assembly is correctly aligned and installed.

4.4 - Place coupling on valve stem, if necessary, and position actuator on mounting brackets. Aligne valve

and actuator assembli so as to eliminate shear force on system.

Rotate the actuator to open direction (normally counter clockwise) as regards to the valve until to eliminate all

torsional play in closing direction, just to get correct closing valve position in corrispondence of actuator closing

position (piston close to piston, see figures 1A and 1C), then tighten all assembly fasteners to appropriate torque

specification given in table 3, pag. 9).

IS O

Dimension A

ISO

Dimension B

FIGURA 2

Bottom view of the actuator

with ISO standard mounting dimensions.

TIPO Dimens. A Dimens. B

ISO mm ISO mm.

GTX. 52 F03 36 F05 50

GTX. 63 F05 50 F07 70

GTX. 75 F05 50 F07 70

GTX. 83 F05 50 F07 70

GTX. 92 F05 50 F07 70

GTX.110 F07 70 F10 102

GTX.118 F07 70 F10 102

GTX.127 F07 70 F10 102

GTX.143 F10 102 F12 125

GTX.160 F10 102 F12 125

GTX.190 F14 140

GTX.210 F14 140

GTX.254 F16 165

GTX.255 F16 165

GTX.300 F16 165

Loading...

Loading...