Fig.O

6. CHECKING OIL SUPPLY (Fig. N)

Keep clear of the saw chain as it will start rotating upon

starting of engine.

After starting the engine, run the chain at medium

speed and see if chain oil is scattered off as shown in

the figure.

The chain oil flow can be changed by inserting a

screwdriver in the hole in bottom of the clutch side.

Adjust according to your work conditions.

NOTE:The oil tank should become nearly empty by the

time fuel is used up. Be sure to refill the oil tank every

time when refueling the unit.

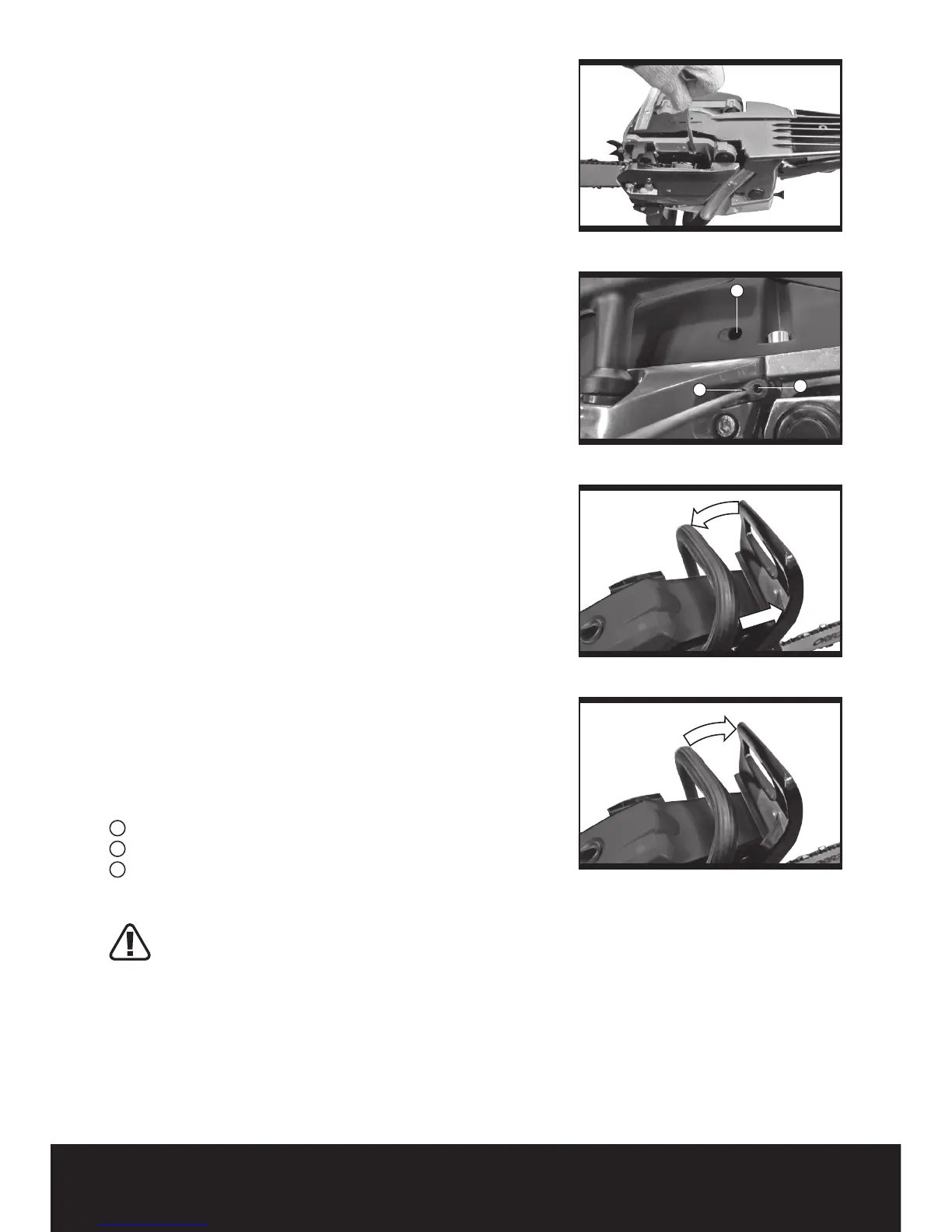

7. ADJUSTING CARBURETOR (Fig. O)

The carburetor on your unit has been factory adjusted,

but may require fine tuning due to change in operating

conditions. Before adjusting the carburetor, make

sure that provided are clean air/fuel filters and fresh,

properly mixed fuel. When adjusting, take the following

steps:

NOTE: Be sure to adjust the carburetor with the bar

chain attached

1) Stop engine and screw in both H and L needles until

they stop. Never force. Then set them back the initial

number of turns as shown below.

L NEEDLE: 1

1/4

H NEEDLE: 1

3/8

2) Start engine and allow it to warm up at OPEN-

throttle.

3) Turn L needle slowly clockwise to find a position

where idling speed is maximum, then set the needle

back a quarter(1/4)turn counterclockwise

4) Turn idle adjusting screw (T) counterclockwise to

that saw chain dose not turn. If idling speed is too

slow, turn the screw clockwise.

5) Make a test cut and adjust the H needle for best

cutting power, not for maximum speed.

4

L needle

5

H needle

6

Idle adjusting screw

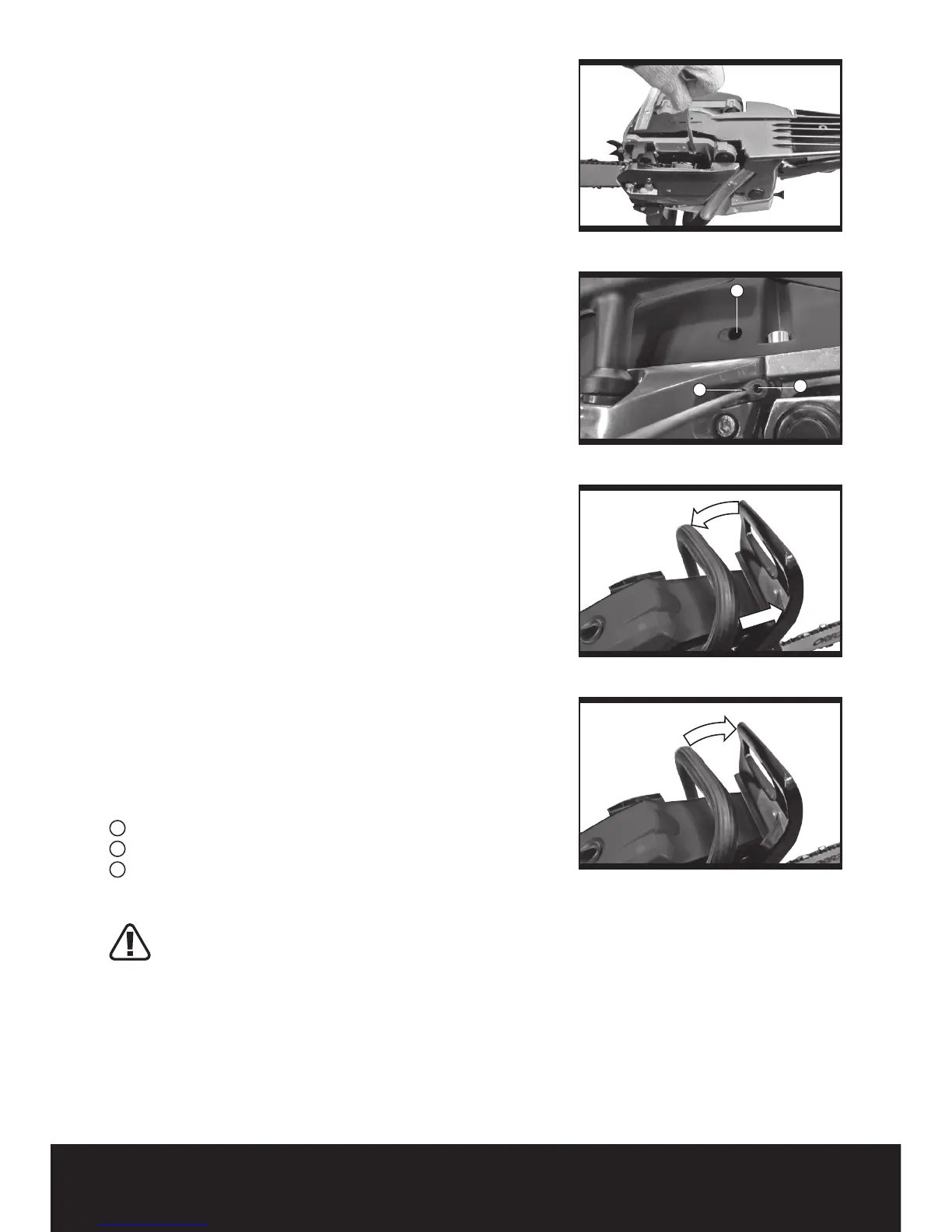

8. CHAIN BRAKE (Fig. P1&P2)

WARNING: If the brake band is worn too thin

it may break when the chain brake is triggered.

DO NOT USE IT. It must be replaced by the

manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard. With

a broken brake band, the chain brake will not stop

the chain. The chain brake should be replaced by an

authorized service dealer if any part is worn to less

than 0.5 mm (0.020”) thick. Repairs on a chain brake

Fig.P1

Fig.P2

Loading...

Loading...