3

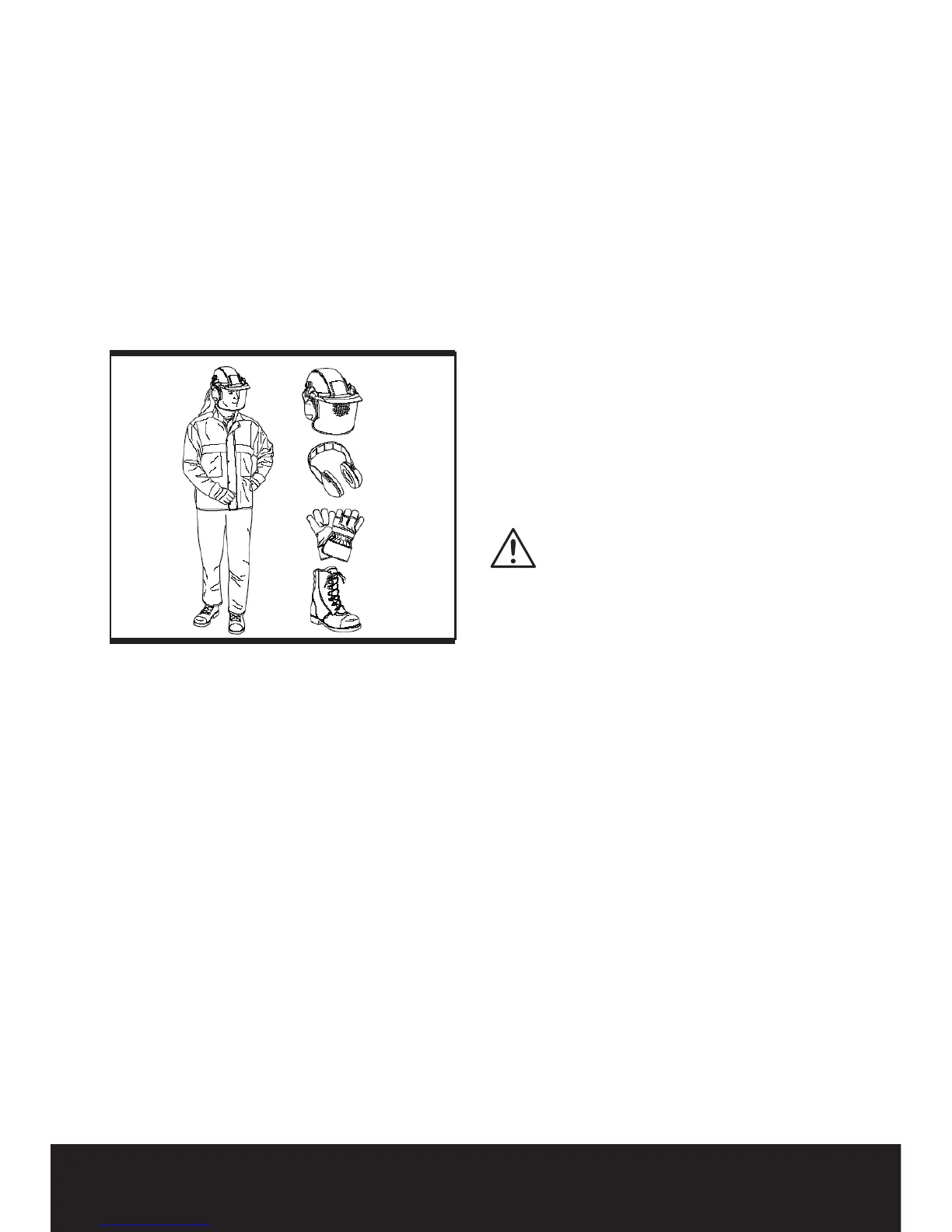

Good footing is most important in chain saw

work.

Wear sturdy boots with nonslip soles. Steel-toed

safety boots are recommended.

Proper eye protection is a must. Non-

fogging, vented goggles and a face screen is

recommended. Their use reduces the risk of eye

and facial injury.

Wear an approved safety hard hat to protect

your head. Chain saw noise may damage your

hearing.

Always wear noise protection equipment (ear

plugs or ear muffs) to protect your hearing.

Continual and regular users should have their

hearing checked regularly.

A

MAINTAIN THE SAW IN GOOD WORKING

ORDER

1. Have all chain saw service performed by a

qualified service dealer with the exception of

the items listed in the maintenance section of

this manual. For example, if improper tools

are used to remove or hold the flywheel when

servicing the clutch, structural damage to the

flywheel can occur and cause the flywheel to

burst.

2. Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to:

CARBURETOR ADJUSTMENT.

1. Never modify your saw in any way.

2. Keep the handles dry, clean, and free of oil or

fuel mixture.

3. Keep fuel and oil caps, screws, and fasteners

securely tightened.

4. Use only qualified accessories and

replacement parts as recommended.

HANDLE FUEL WITH CAUTION

1. Do not smoke while handling fuel or while

operating the saw.

2. Eliminate all sources of sparks or flame in the

areas where fuel is mixed or poured. There

should be no smoking, open flames, or work

that could cause sparks. Allow engine to cool

before refueling.

3. Mix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes. Wipe

up all fuel spills before starting saw.

4. Move at least 3 meters from fueling site

before starting engine.

5. Turn the engine off and let saw cool in a non-

combustible area, not on dry leaves, straw,

paper, etc. Slowly remove fuel cap and refuel

unit.

6. Store the unit and fuel in an area where

fuel vapors cannot reach sparks or open

flames from water heaters, electric motors or

switches, furnaces, etc.

KICKBACK SAFETY PRECAUTIONS

WARNING! Kickback may occur when

the moving saw chain near the upper

quadrant of the bar nose contacts a solid object

or is pinched.

The reaction of the cutting force of the chain

causes a rotational force on the chainsaw in the

direction opposite to the chain movement. This

may fling the bar up and back in an uncontrolled

arc mainly in the plane of the bar. Under some

cutting circumstances the bar moves towards

the operator, who may suffer severe or fatal

injury.

Kickback may occur when the nose of the guide

bar is pinched unexpectedly, unintentionally

contacts solid material in the wood or is

incorrectly used to begin a plunge or boring cut.

It may also occur during limbing. The greater the

force of the kickback reaction, the more difficult

it becomes for the operator to control the saw.

Many factors influence the occurrence and force

of the kickback reaction. These include chain

speed, the speed at which the bar and chain

contact the object, the angle of contact, the

condition of the chain and other factors.

Pull-in occurs when the chain on the bottom of

the bar is suddenly stopped when it is pinched,

caught or encounters a foreign object in the

wood. The reaction of the chain pulls the saw

forward and may cause the operator to lose

control.

Pull-in frequently occurs when the bumper spike

Loading...

Loading...