Offset Conduit Conduit Conduit

Required Max. Size M Max. Size M Max. Size M

2"

3

⁄4" 7

3

⁄4"

4" 1

1

⁄2" 15

7

⁄16"

3

⁄4" 8"

6" 2" 23

3

⁄16" 1" 12"

1

⁄2” 8

1

⁄2"

8" 30

5

⁄8" 1

1

⁄2" 16" 1” 11

5

⁄16"

10" 38

5

⁄8" 2" 20" 1

1

⁄4” 14

1

⁄8"

12" 46

3

⁄8" 24" 1

1

⁄2” 16

15

⁄16"

14" 54

1

⁄16" 28" 2" 19

13

⁄16"

16" 61

13

⁄16" 32" 22

5

⁄8"

18" 67

7

⁄16" 36" 25

7

⁄16"

20" 77

1

⁄4" 40" 28

1

⁄4"

22" 85" 44” 31

1

⁄8"

To locate distance between centers of offset bending marks other than

listed in table A use the following multipliers:

15° bend - 3.9

30° bend - 2.0

45° bend - 1.4

Table A

15° Bend 30° Bend 45° Bend

4.4 Stub-up Bending

1. Table C shows minimum length (inches).

2. Mark #1 is stub length, deduct from this as per table C

and obtain mark #2.

Conduit Radius Radius

Size Rigid / IMC EMT

1

⁄2" 3

31

⁄32" 3

7

⁄8"

3

⁄4" 4

25

⁄32" 4

29

⁄32"

1" 5

9

⁄16" 5

29

⁄32"

1

1

⁄4" 6

7

⁄8" 7

3

⁄32"

1

1

⁄2" 7

9

⁄16" 7

1

⁄2"

2" 8

9

⁄32" 8

9

⁄16"

Table B

BEND RADIUS

Shoe

Min. 2"

Stub Length

Set Back

Mark #2

Mark #1

Front Edge of

Clamp Mark #2

Stub to Bottom

of Pipe

1

⁄2" Rigid 7

3

⁄4" 1

1

⁄4" Rigid 12

3

⁄4"

1

⁄2" IMC 7

3

⁄4" 1

1

⁄4" IMC 12

1

⁄2"

1

⁄2" EMT 7

5

⁄8" 1

1

⁄4" EMT 13"

3

⁄4" Rigid 9" 1

1

⁄2" Rigid 13

1

⁄2"

3

⁄4" IMC 9" 1

1

⁄2" IMC 13

1

⁄2"

3

⁄4" EMT 8

1

⁄2" 1

1

⁄2" EMT 13

1

⁄2"

1" Rigid 10

1

⁄8" 2" Rigid 15

3

⁄4"

1" IMC 10

1

⁄8" 2" IMC 15

1

⁄2"

1" EMT 10

3

⁄8" 2" EMT 15

1

⁄2"

Table C

Conduit Stub-up Conduit Stub-up

Size Set-back Size Set-back

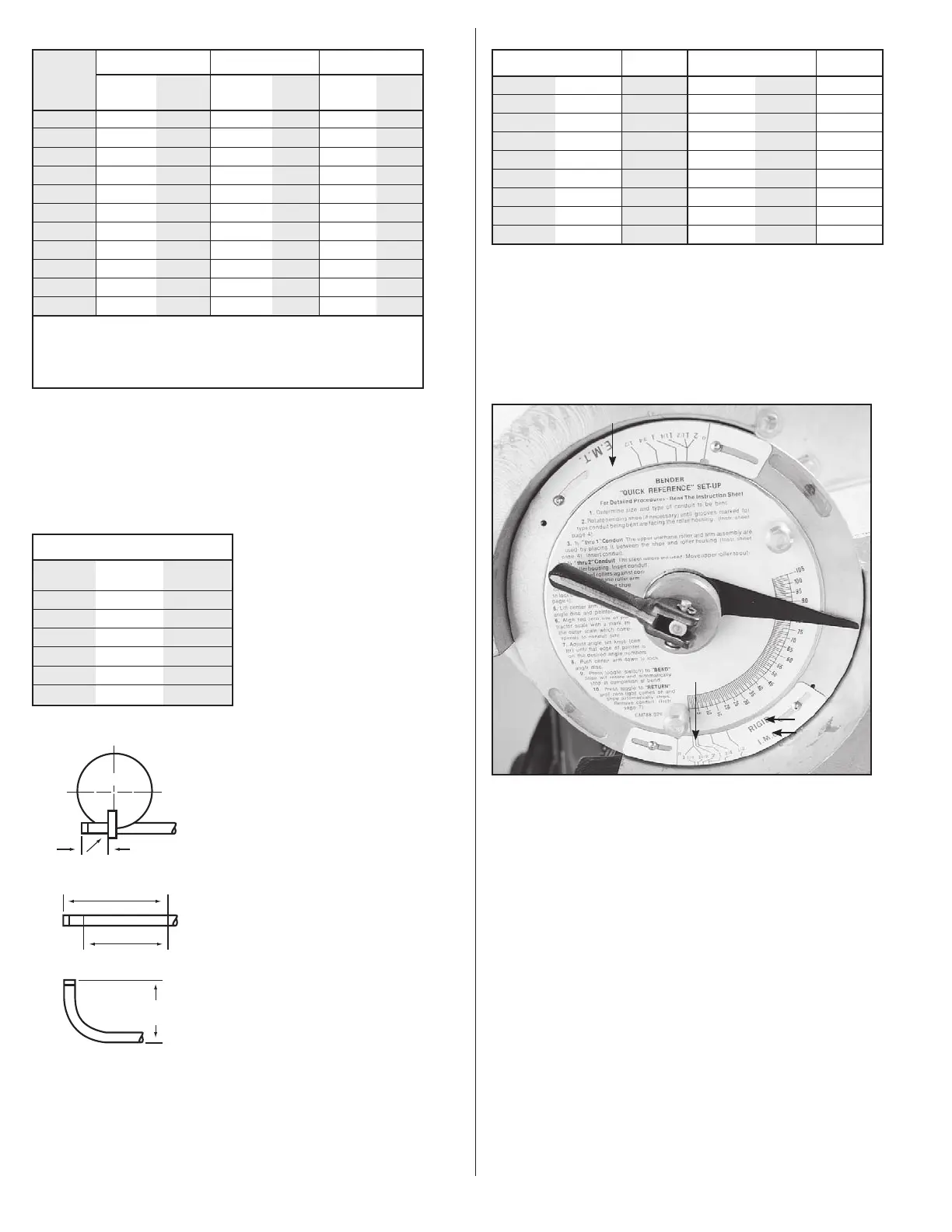

5.0 ANGLE ADJUSTMENT

Two different type scales are mounted on the shoe outer rim.

One for

1

⁄2" thru 2" IMC and Rigid, the other for EMT

1

⁄2" thru 2"

See Figure 12.

Each scale indicator is adjustable to compensate for over long

or short bends which may be due to differences in conduit

characteristics or other variations.

Type Scale

Roller Support Arm

Locking Handle

Upper Urethane Roller

EMT Size Scale

Note: Two

scales one

for rigid

and one

for IMC

Type Scale

Type Scale

Figure 12. Two Type Scales

Bends which are too long: Loosen the size scale (for type material

being bent) mounting screws. Slide the scale clockwise as many

degrees as the overbend (if bend is 5° over, move indicator 5°

clockwise). The degree of movement is observed by watching one

of the size marks as it moves past the angle disc scale. Tighten

the mounting screws.

Bends which are too short: Loosen the size scale (for type material

being bent) mounting screws. Slide the scale counterclockwise

as many degrees as the bend is short (if bend is 5° short move

counterclockwise 5°). The degree movement is observed by watching

one of the size marks as it moves past the angle disc scale. Tighten

the mounting screws.

6

Loading...

Loading...